Non-woven fabric hot rolling device

A non-woven, hot-pressing roller technology, applied in non-woven fabrics, textiles and papermaking, heating/cooling fabrics, etc., can solve the problems of inconvenient adjustment of the degree of compression, poor non-woven forming effect, and long time spent. , to achieve the effect of high processing efficiency, short time and easy winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

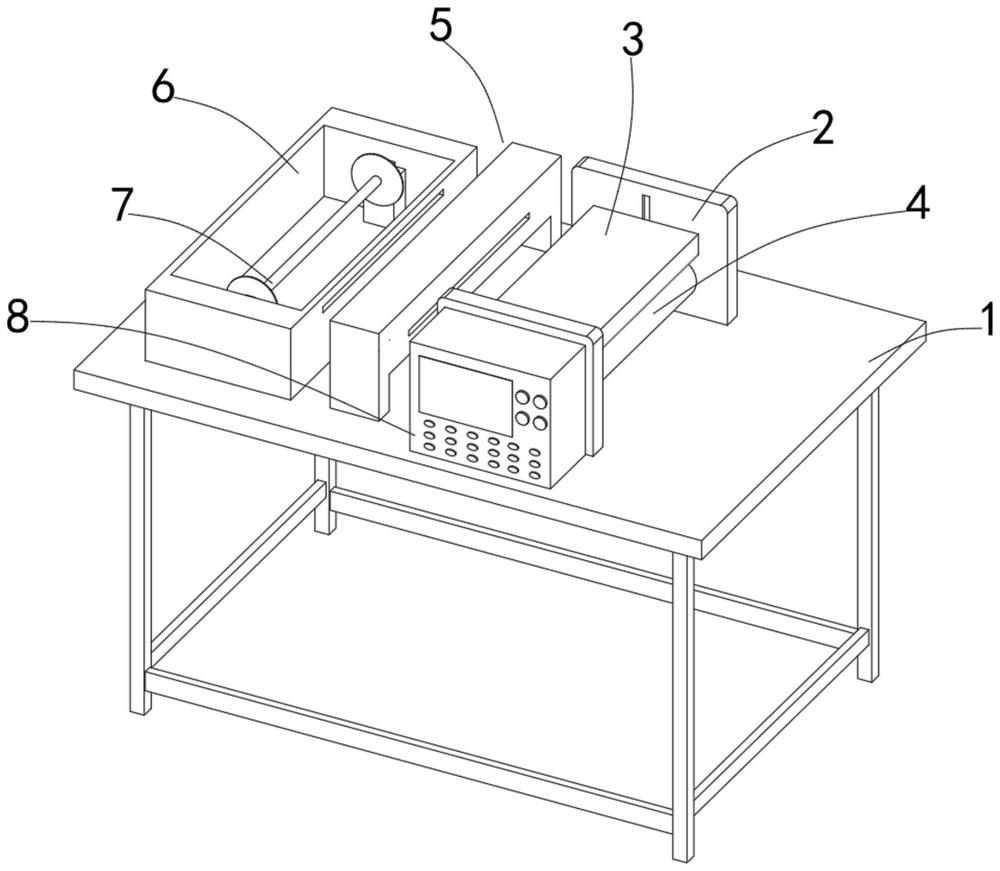

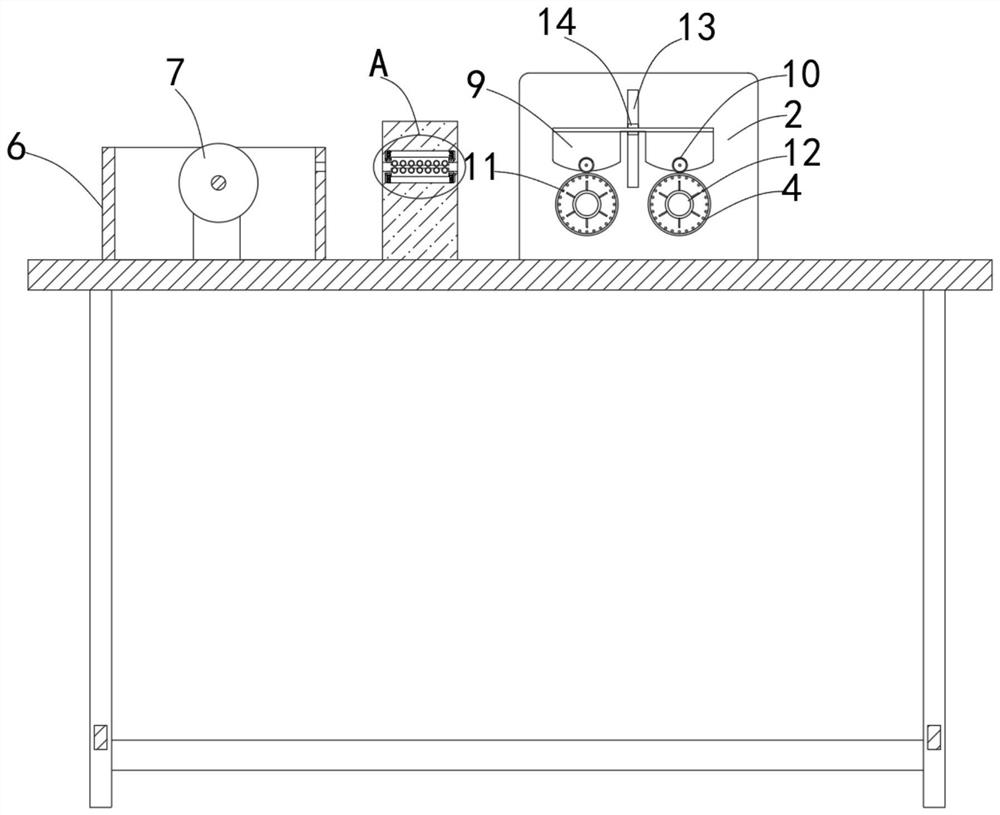

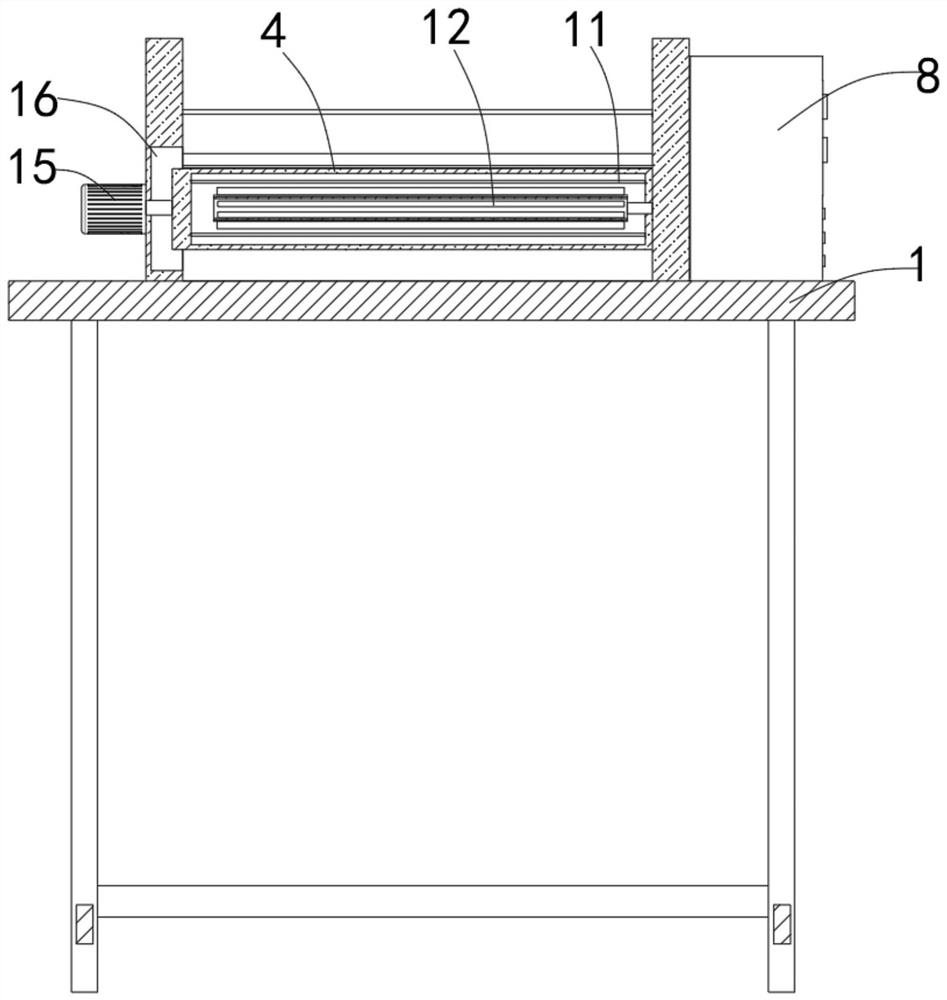

[0025] Example 1, please refer to figure 1 , 2 , 3 and 4, the hot-rolling device of non-woven fabric, comprises table body 1, and the upper end of table body 1 is respectively provided with hot-rolling mechanism, cooling mechanism 5 and the winding groove 6 that is used for winding, and the inside of winding groove 6 Rewinding roll 7 is detachably arranged, and the hot rolling mechanism includes side plate 2, and there are two side plates 2 in total, and hot pressing roll 4 is arranged between side plates 2 on both sides, and one side of side plate 2 is provided with control End 8, the inside of the heat-pressing roller 4 on both sides is provided with a cavity 11 for storing heat-conducting medium, and the inside of the cavity 11 on both sides is provided with a stirring shaft 12, and one end of the stirring shaft 12 runs through the heat-pressing roller 4 and one side The plate 2 is fixedly connected, one of the hot pressing rollers 4 on both sides is rotated with the side ...

Embodiment 2

[0026] Example 2, please refer to figure 1 , 2 and 3 and 4, the cooling mechanism 5 includes a connecting frame 51, the middle part of the connecting frame 51 is provided with a slot 53, and the upper and lower ends of the slot 53 are provided with grooves 52, and both sides of the upper and lower ends of the groove 52 are A chute 57 is opened, and connecting plates 55 are slidably connected to the inside of the adjacent chute 57 on both sides, and cooling plates 54 are connected between the connecting plates 55 on both sides, and cooling pipes are installed at equal intervals inside the cooling plates 54 at the upper and lower ends 56, both sides of the upper and lower ends of the groove 52 are connected with connecting columns 59, and the outside of each connecting column 59 is provided with a spring 58, and the two ends of each cooling pipe 56 are communicated with the external cooling pipe through the main pipe, and the heat The rolled non-woven fabric passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com