Hydroscopic and fast dry spandex fiber and preparation method thereof

A technology of spandex fiber, moisture absorption and quick drying, applied in dry spinning, fiber chemical characteristics, rayon manufacturing and other directions, to achieve the effect of improving moisture absorption capacity, improving grade, and mature manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

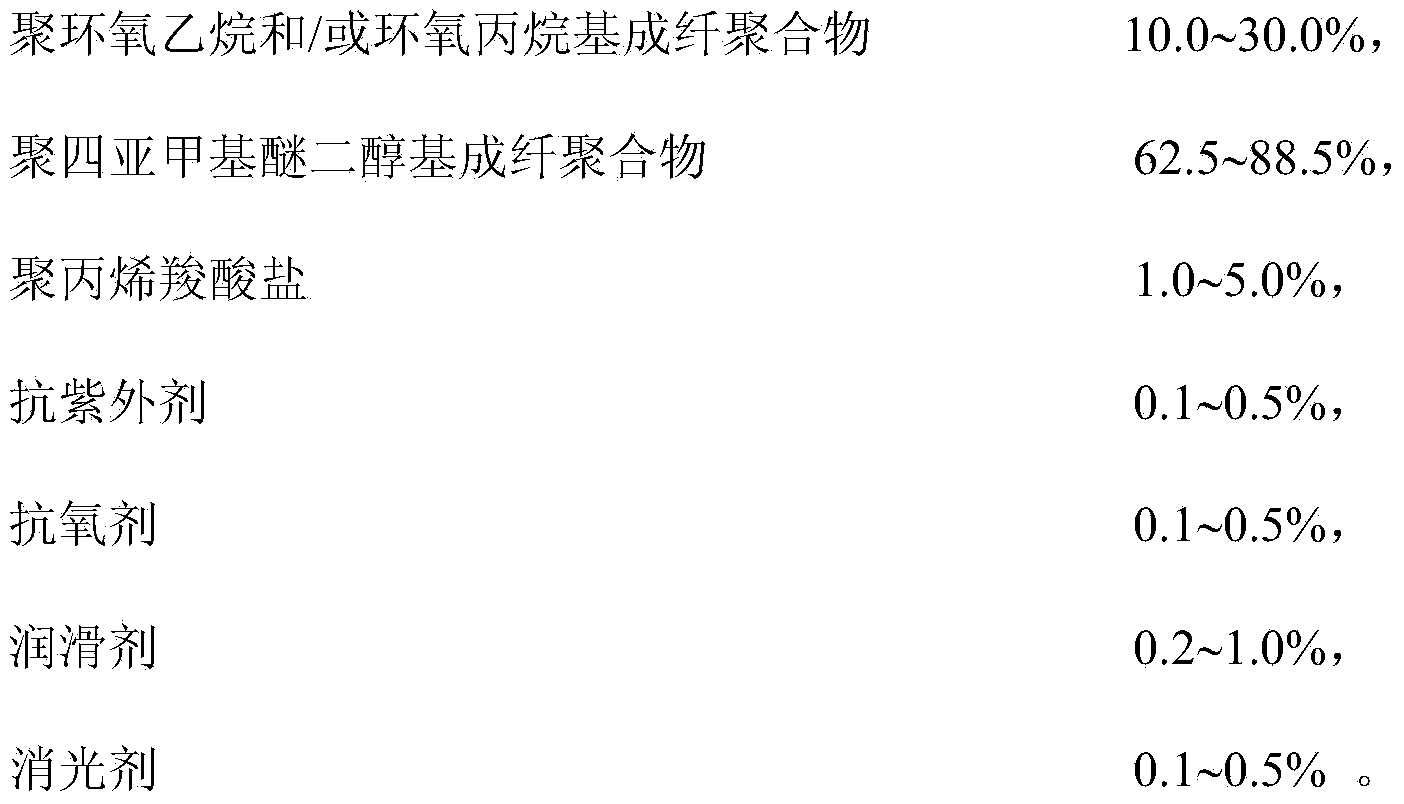

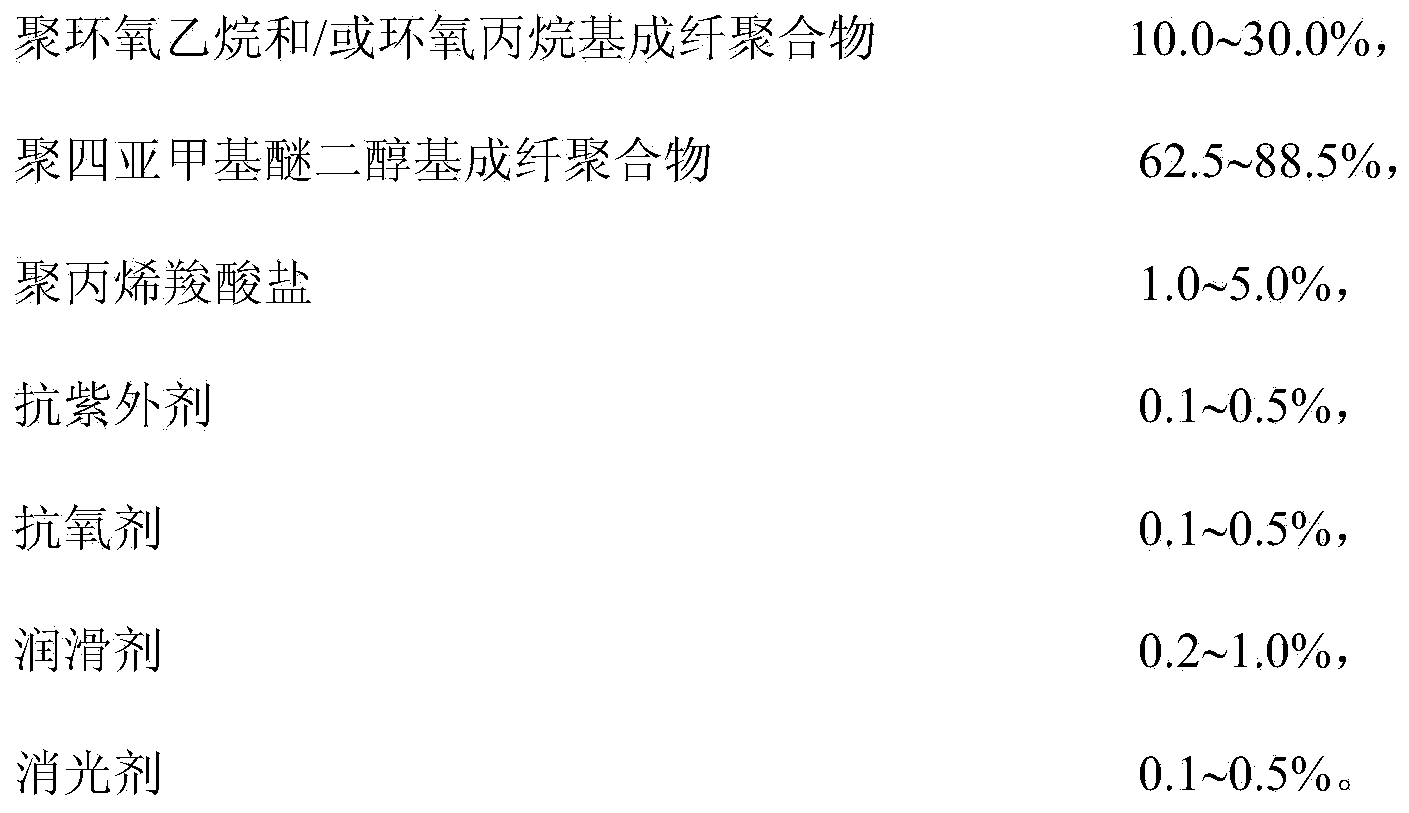

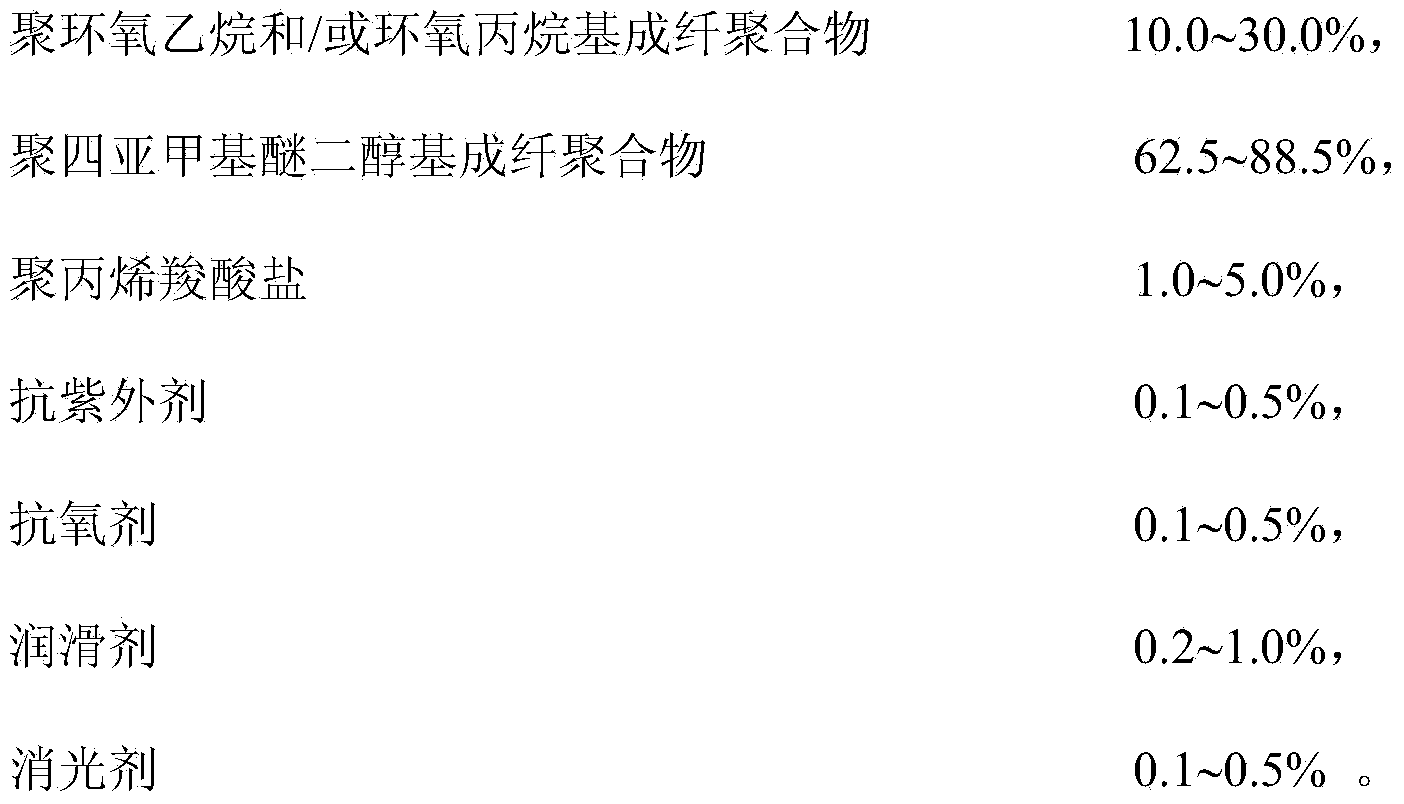

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Preparation of prepolymer solution

[0029] 1) Mix the raw materials polytetramethylene ether glycol and 4,4'-diphenylmethane diisocyanate, and react at 75-90°C for 120 minutes to prepare prepolymer 1, in which 4,4'-diphenylmethane The molar ratio of diisocyanate to polytetramethylene ether glycol is 1.80:1;

[0030] 2) Mix the raw materials polyethylene oxide and 4,4'-diphenylmethane diisocyanate in N,N-dimethylacetamide with a concentration of 50.0% by mass, and react at 80°C for 150 minutes to prepare the pre- Polymer 2, wherein the molar ratio of 4,4'-diphenylmethane diisocyanate to polyethylene oxide is 1.90:1;

[0031] 3) Mix the prepolymer 1 and the prepolymer 2 evenly, dissolve them into the solvent N,N-dimethylacetamide to obtain a prepolymer solution, and store it at a temperature of 45°C.

[0032] Step 2: Preparation of fiber-forming polymer

[0033] 1) Dissolving one or both of ethylenediamine and butylenediamine into the solvent N,N-dimethylaceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com