High-solid-content low-viscosity odorless hydroxyl polyurethane resin as well as preparation method and application thereof

A clean-odor hydroxypolyurethane, low-viscosity technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor film compactness, residual odor, and high temperature in the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of a high-solid, low-viscosity, clean-odor hydroxyl polyurethane resin

[0054] In parts by mass, the raw material components and consumption are as follows in Table 1

[0055] Table 1

[0056]

[0057] The preparation process comprises the following steps:

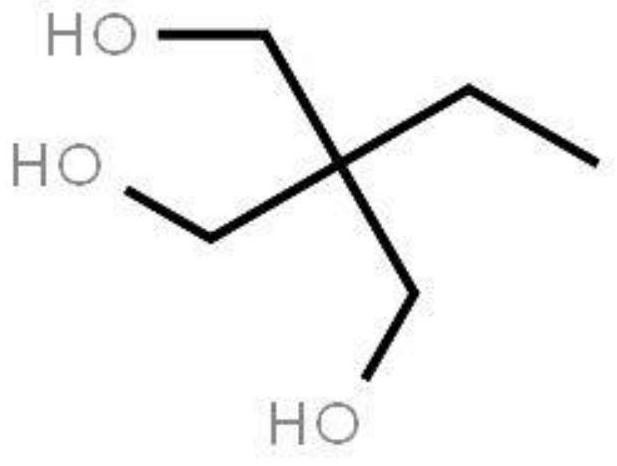

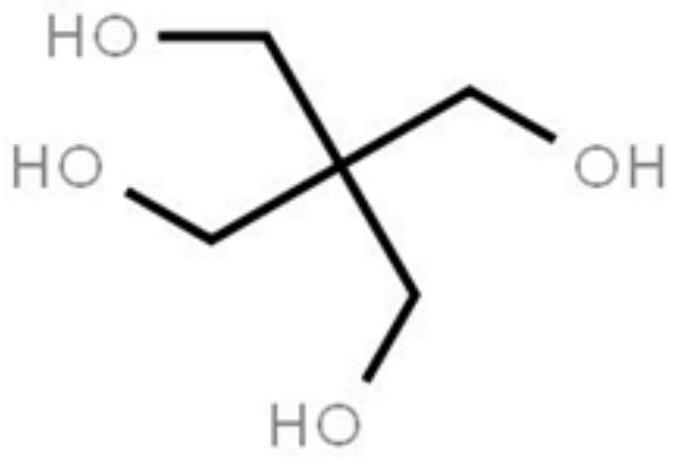

[0058] (1) Preparation of hydroxypolyols with star-shaped branched structure: trimethylolpropane, phthalic anhydride and p-toluenesulfonic acid (catalyst one) and a small amount of ethyl acetate are added to the reactor, and the temperature is raised Stir at 120°C, keep warm at 120°C for 2 hours, measure the acid value of the resin below 155mgKOH / g; add epichlorohydrin and tetrabutylammonium bromide (catalyst 2) to the above system, Keep warm for 5 hours, measure the acid value of the resin below 12.0mgKOH / g; lower the temperature below 90°C, and distill under reduced pressure for 1-3h at a vacuum degree of 0.06-0.08MPa to remove excess water and solvents to obtain hydroxyl groups with a star-s...

Embodiment 2

[0082] (1) Preparation of a high-solid, low-viscosity, clean-odor hydroxyl polyurethane resin

[0083] In parts by mass, the raw material components and consumption are as shown in Table 5

[0084] table 5

[0085]

[0086] The preparation process comprises the following steps:

[0087] (1) Preparation of hydroxypolyols with star-shaped branched structure: Pentaerythritol, maleic anhydride, hexahydrophthalic anhydride and p-toluenesulfonic acid monohydrate (catalyst one) and a small amount of ethyl acetate are added to the reactor, and the temperature is raised To 115°C, start stirring, keep warm at 115°C for 2 hours, measure the acid value of the resin below 150mgKOH / g; add benzyl glycidyl ether and tetraethylammonium bromide (catalyst two) to the above system, Insulate at ℃ for 7 hours, measure the acid value of the resin below 12.0mgKOH / g; cool down below 90℃, and distill under reduced pressure for 1-3h at a vacuum degree of 0.06-0.08MPa to remove excess water and solv...

Embodiment 3

[0102] (1) Preparation of a high-solid, low-viscosity, clean-odor hydroxyl polyurethane resin

[0103] In parts by mass, the raw material components and consumption are as shown in Table 9

[0104] Table 9

[0105]

[0106]

[0107] The preparation process comprises the following steps:

[0108] (1) Preparation of hydroxypolyols with star-shaped branched structure: Pentaerythritol, succinic anhydride, methyl hexahydrophthalic anhydride and p-toluenesulfonic acid (catalyst one) and a small amount of ethyl acetate are added to the reactor, and the temperature is raised Stir at 120°C, keep warm at 125°C for 3 hours, measure the acid value of the resin below 150mgKOH / g; add tert-butyl glycidyl ether and triphenylphosphine (catalyst 2) to the above system, Insulate for 6 hours, measure the acid value of the resin below 12.0mgKOH / g; cool down below 90°C, and distill under reduced pressure for 1-3h at a vacuum of 0.06-0.08MPa to remove excess water and solvents to obtain hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com