Comprehensive recovery method for waste iron-based diamond tool

A technology for discarding iron and funds, applied in the field of comprehensive utilization of resources, can solve the problems of a large number of toxic gases, the sneak discharge of pollutants, and the low value of recycled materials, and achieve the effects of environmental protection, shortening time, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

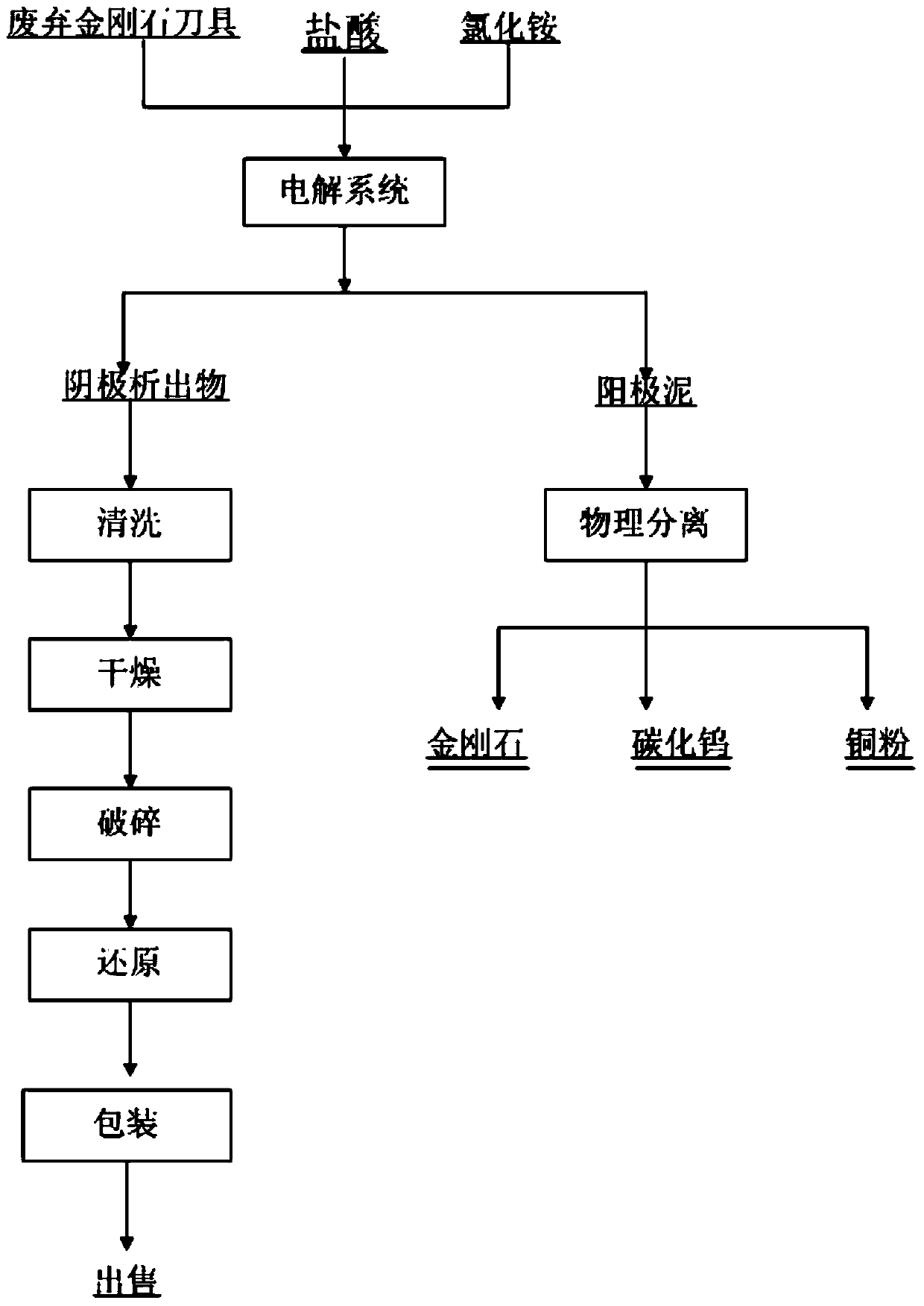

Image

Examples

Embodiment 1

[0040] Wash the waste iron-based diamond tools and put them into mesh titanium blue with a size of 550mm×450*80 as the anode, and a 316L stainless steel plate with a size of 600*500*2 as the cathode (the effective area of cathode electrolysis is 0.5 square meters / Block), the anode and cathode are installed in the electrolytic cell with the pole distance of 100mm. In the waste iron-based diamond tool, there are 2 wt% of diamond, 65-70 wt% of iron powder, 10-30 wt% of copper powder, 1 wt% of nickel powder, about 2-3 wt% of zinc and a trace amount of tungsten carbide.

[0041] In this embodiment, a PVC tank with a size of 800mm×800mm×700mm is used as an electrolytic tank, and a PVC tank with a size of 1000mm×1000mm×600mm is used as an electrolyte circulation tank. The circulation tank is equipped with a filter device, and the filtered electrolyte is pumped into the electrolytic tank through a circulation pump, iron is dissolved at the anode, and electrolytic iron sheets are ob...

Embodiment 2

[0051] Change the following conditions, and other conditions are the same as in Example 1;

[0052] After making liquid electrolysis until the concentration of ferrous ions in the electrolyte is 50g / L, after controlling the pH value of the reaction system to 3.0-3.5, lower the strength of the electrolytic liquid to 800A (at this time, the current density of the cathode is 400A / m2, The cell voltage is 3.2V), the circulation speed of the electrolyte is controlled at 40L / min, and the electrolytic recovery of waste diamond tools is carried out. The electrolytic recovery process takes 20 hours as a cycle, and the weight of the cathode deposit obtained in one electrolysis cycle is 15.67 kg; during the recovery process, the average current efficiency of the cathode is controlled to be 94%; the obtained cathode deposit is cleaned, dried, crushed and reduced, and then packaged for sale.

Embodiment 3

[0062] After the completion of Example 1, add waste iron-based diamond tools to the titanium anode blue to continue recycling electrolysis; control the current density of the cathode during recycling electrolysis to be 350A / m 2, the cell voltage is 2.8V, the circulation speed of the electrolyte is controlled at 50L / min, and the electrolytic recovery of waste diamond tools is carried out. The electrolytic recovery process takes 24 hours as a cycle, and the weight of the cathode deposit obtained in one electrolysis cycle is 15.40 kg; during the recovery process, the average current efficiency of the cathode is controlled to be 88%; the obtained cathode deposit is cleaned, dried, crushed and reduced, and then packaged for sale.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com