System and method for recycling Fischer-Tropsch synthetic wastewater in indirect coal liquefaction production

A technology for Fischer-Tropsch synthetic wastewater and wastewater, applied in the direction of neutralization water/sewage treatment, etc., can solve problems such as blocked pipes, corrosion of pumps and pipelines, high safety risks, etc., to avoid load reduction operations, save economic losses, and avoid Effects of Security Risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

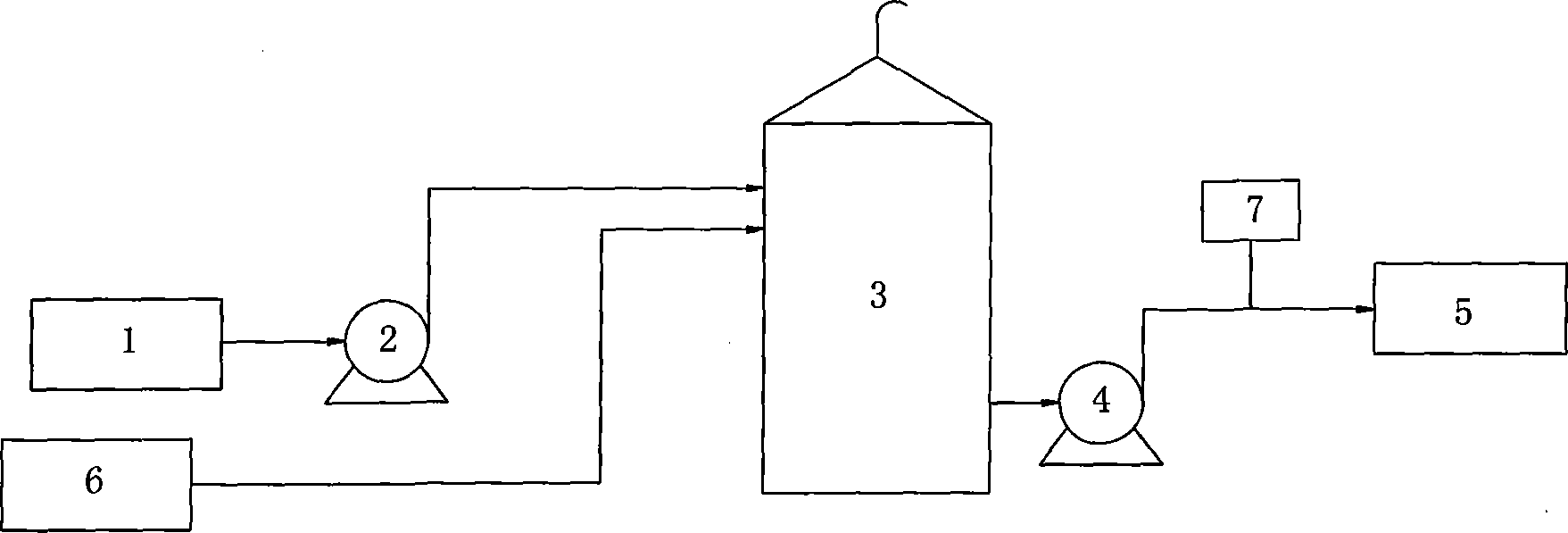

[0022] Embodiment 1: A Fischer-Tropsch synthetic wastewater recycling system in indirect coal liquefaction production, which includes an ammonia-containing wastewater storage device 1, an ammonia-containing wastewater pump 2, a pulping tank 3, a pulping water pump 4, and a coal-water slurry preparation device 5 and the F-T synthesis device 6, the outlet of the ammonia-containing wastewater storage device 1 is connected with the inlet of the ammonia-containing wastewater pump 2, the outlet of the ammonia-containing wastewater pump 2 is connected with the ammonia-containing wastewater inlet of the pulping tank 3, the F-T synthesis device 6 The wastewater outlet is connected to the Fischer-Tropsch synthetic wastewater inlet of the pulping tank 3, the outlet of the pulping tank 3 is connected to the inlet of the pulping water pump 4, and the outlet of the pulping water pump 4 is connected to the water inlet of the coal-water slurry preparation device 5. An online pH value monitorin...

Embodiment 2

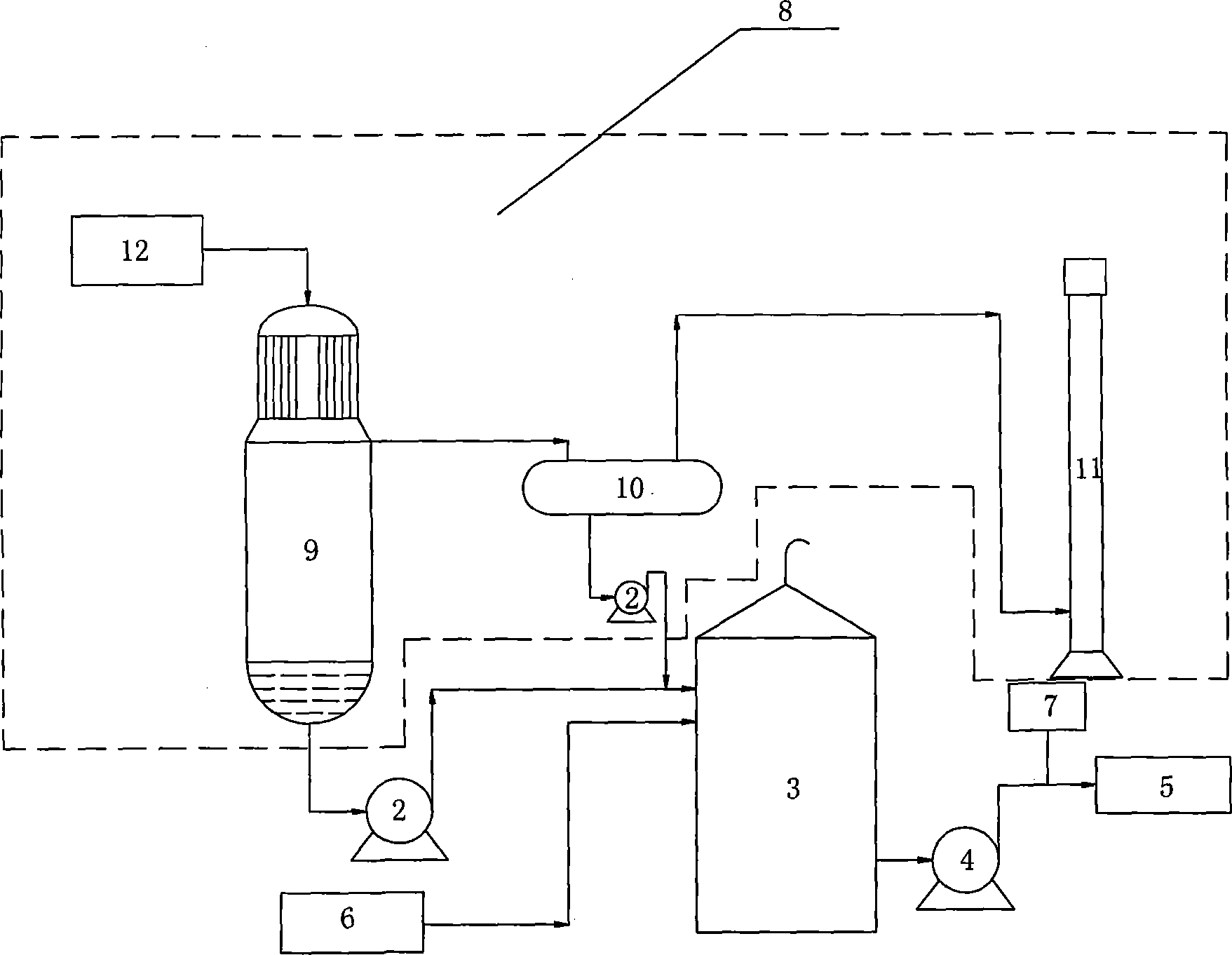

[0023] Embodiment 2: On the basis of embodiment 1, a kind of Fischer-Tropsch synthetic waste water recycling system in coal indirect liquefaction production also includes ammoniacal waste water treatment device 8, and ammoniacal waste water treatment device 8 includes conversion unit ammonia steam Lifting device 12, ammonia-containing steam condenser 9, acid gas separation tank 10 and acid gas torch 11, the top of ammonia-containing steam condenser 9 is provided with ammonia-containing steam inlet, and the bottom of ammonia-containing steam condenser 9 is provided with water outlet, The upper part of the ammonia-containing steam condenser 9 is provided with a circulating cooling water non-condensable gas outlet, and the ammonia-containing steam inlet of the ammonia-containing steam condenser 9 is connected with the ammonia-containing steam outlet of the conversion unit ammonia stripping device 12, and the ammonia-containing steam condenser The water outlet at the bottom of 9 is...

Embodiment 3

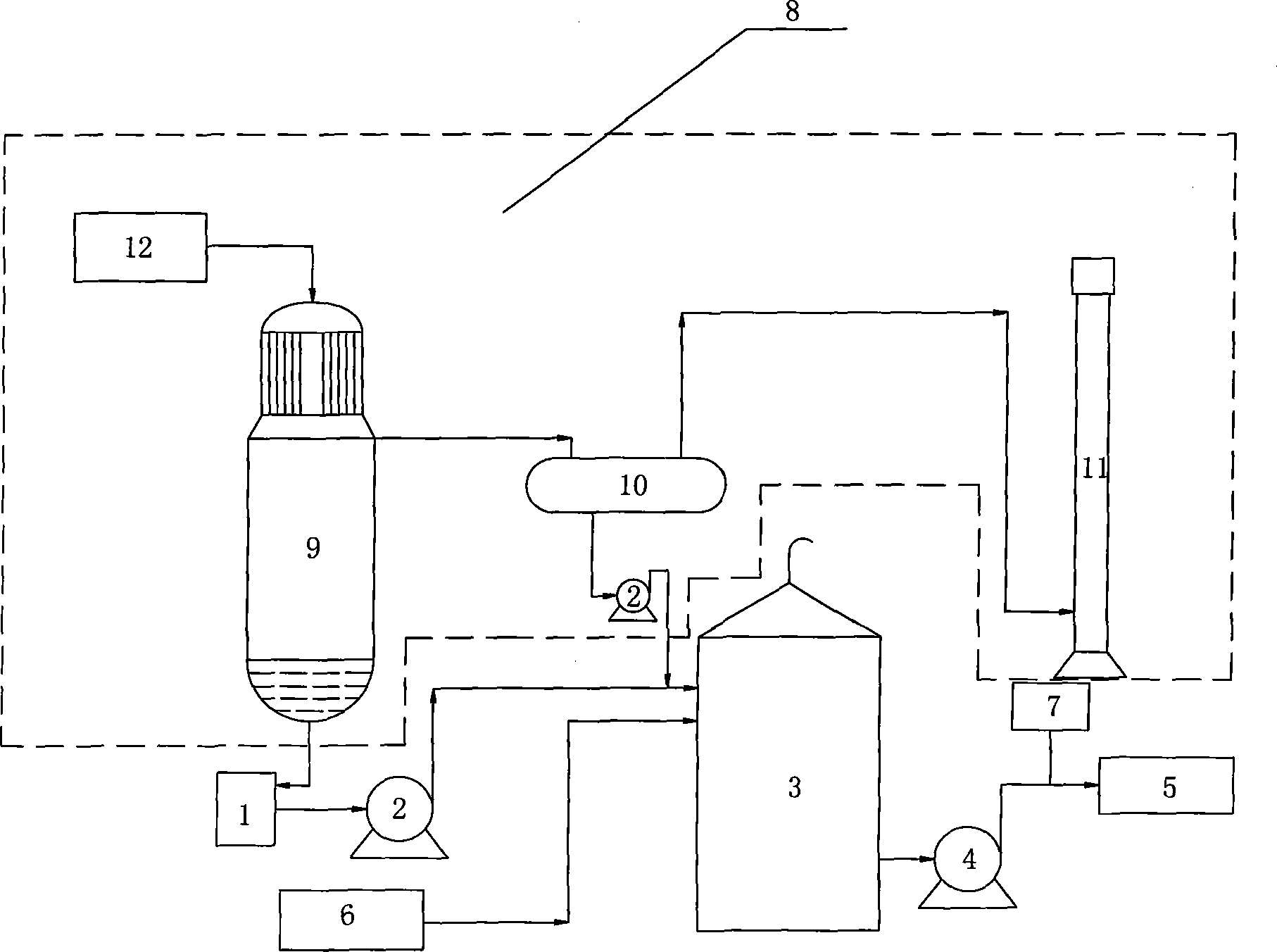

[0024]Embodiment 3: On the basis of embodiment 1, a kind of Fischer-Tropsch synthetic waste water recycling system in coal indirect liquefaction production also includes ammoniacal waste water treatment device 8, ammoniacal waste water treatment device 8 includes conversion unit ammonia steam Lifting device 12, ammonia-containing steam condenser 9, acid gas separation tank 10 and acid gas torch 11, the top of ammonia-containing steam condenser 9 is provided with ammonia-containing steam inlet, and the bottom of ammonia-containing steam condenser 9 is provided with water outlet, The upper part of the ammonia-containing steam condenser 9 is provided with a circulating cooling water non-condensable gas outlet, and the ammonia-containing steam inlet of the ammonia-containing steam condenser 9 is connected with the ammonia-containing steam outlet of the conversion unit ammonia stripping device 12, and the ammonia-containing steam condenser The water outlet at the bottom of 9 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com