Composite liquid acidification and mildew resistance agent and preparation method thereof

A compound liquid and antifungal agent technology, which is applied in application, animal feed, animal feed, etc., can solve the problems of reduced digestion and absorption rate of nutrients, limited water content of materials, and mildew of feed, so as to improve feed maturity and increase Effectiveness of utilizing efficiency and overcoming negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

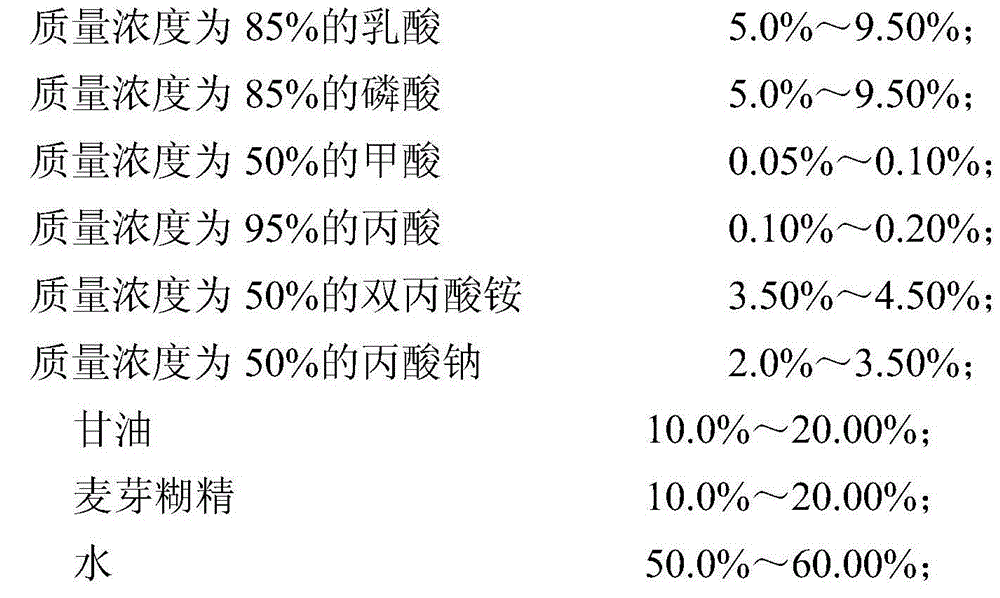

[0020] 1. Weigh raw materials:

[0021]

[0022]

[0023] All the above-mentioned raw materials can be purchased in the raw material market.

[0024] Second, the operation process steps are as follows:

[0025] (1) The preparation of acidifying mildew-proof mixed solution: be that the lactic acid liquid that mass concentration is 85%, the phosphoric acid liquid that mass concentration is 85%, the formic acid liquid that mass concentration is 50%, the propionic acid liquid that mass concentration is 95%, mass concentration Ammonium dipropionate liquid with a concentration of 50%, sodium propionate liquid with a mass concentration of 50%, a total of 6 solutions, mixed uniformly according to the above mass ratio;

[0026] (2) Preparation of uniform mixed phase solution: according to the above mass ratio, dissolve maltodextrin in water, dissolve completely, pour into glycerin and mix evenly; after that, pour in the above-mentioned acidified anti-mold mixed solution, and sti...

Embodiment 2

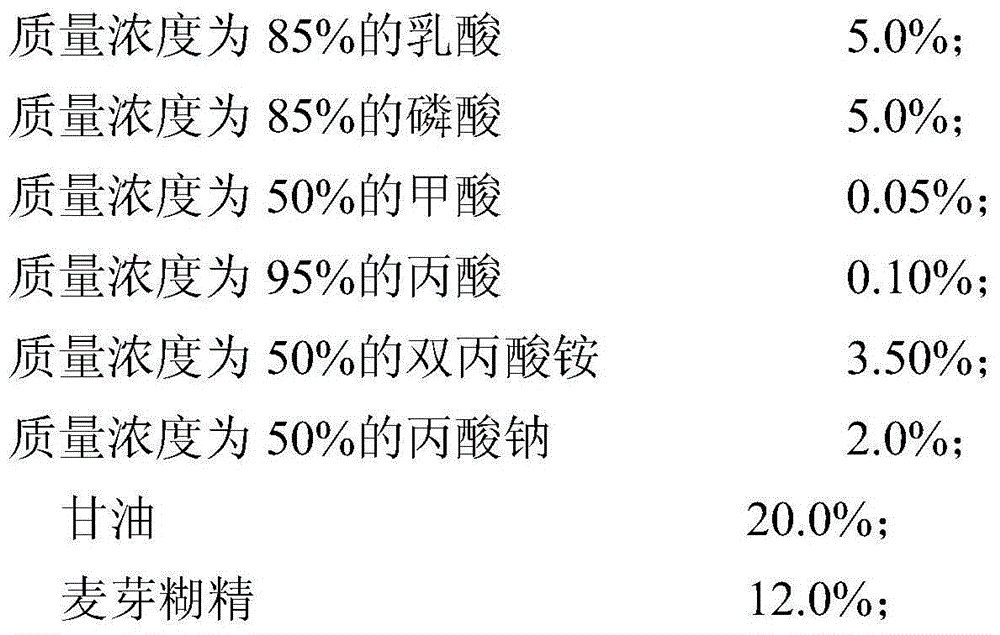

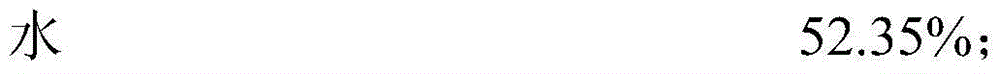

[0031] 1. Weigh raw materials:

[0032]

[0033] All the above-mentioned raw materials can be purchased in the raw material market.

[0034] Second, the operation process steps are as follows:

[0035] (1) The preparation of acidifying mildew-proof mixed solution: be that the lactic acid liquid that mass concentration is 85%, the phosphoric acid liquid that mass concentration is 85%, the formic acid liquid that mass concentration is 50%, the propionic acid liquid that mass concentration is 95%, mass concentration Ammonium dipropionate liquid with a concentration of 50%, sodium propionate liquid with a mass concentration of 50%, a total of 6 solutions, mixed uniformly according to the above mass ratio;

[0036] (2) Preparation of uniform mixed phase solution: according to the above mass ratio, dissolve maltodextrin in water, dissolve completely, pour into glycerin and mix evenly; after that, pour in the above-mentioned acidified anti-mold mixed solution, and stir until the ...

Embodiment 3

[0041] 1. Weigh raw materials:

[0042]

[0043] All the above-mentioned raw materials can be purchased in the raw material market.

[0044] Second, the operation process steps are as follows:

[0045] (1) The preparation of acidifying mildew-proof mixed solution: be that the lactic acid liquid that mass concentration is 85%, the phosphoric acid liquid that mass concentration is 85%, the formic acid liquid that mass concentration is 50%, the propionic acid liquid that mass concentration is 95%, mass concentration Ammonium dipropionate liquid with a concentration of 50%, sodium propionate liquid with a mass concentration of 50%, a total of 6 solutions, mixed uniformly according to the above mass ratio;

[0046] (2) Preparation of uniform mixed phase solution: according to the above mass ratio, dissolve maltodextrin in water, dissolve completely, pour into glycerin and mix evenly; after that, pour in the above-mentioned acidified anti-mold mixed solution, and stir until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com