Anti-seepage sleeve of gear shaft

A technology of gear shaft and sleeve body, applied in the direction of coating, furnace type, furnace, etc., can solve the problems of waste of energy, increase of labor, deviation of anti-seepage area, etc., to improve the quality of anti-seepage, improve production efficiency, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

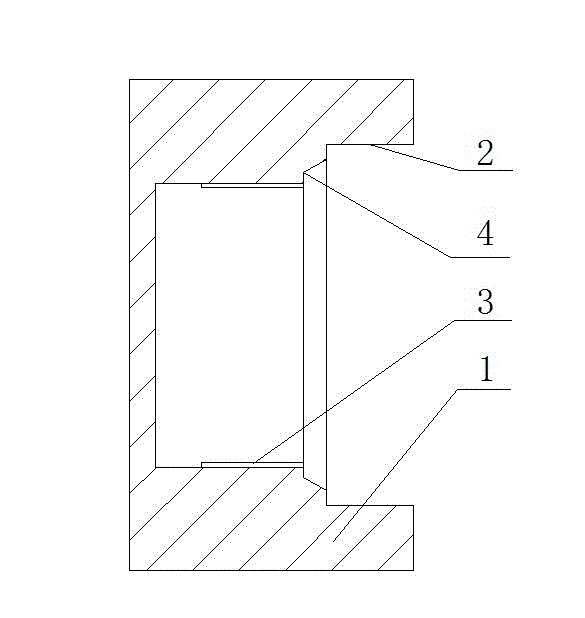

[0008] The invention provides a gear shaft anti-seepage sleeve, which includes a sleeve body 1, the sleeve body 1 is cylindrical, and a circle 2 is arranged at the opening of the sleeve body 1, and the length of the circle 2 is half of the excessive hardness area of the drive shaft. The bottom of sleeve body 1 is provided with thread 3, and thread 3 is threadedly matched with driving shaft, and step 4 is arranged between described thread 3 and circle 2, and step 4 closely cooperates with the step of thread on the driving shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com