Integral triple valve and casting technology thereof

A technology of casting process and valve body, which is applied in the field of integral triple valve body and its casting process, to achieve the effect of wide application range, small space structure and precise size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0054] The invention relates to a metal valve body, in particular to an integral triple valve body and its casting process.

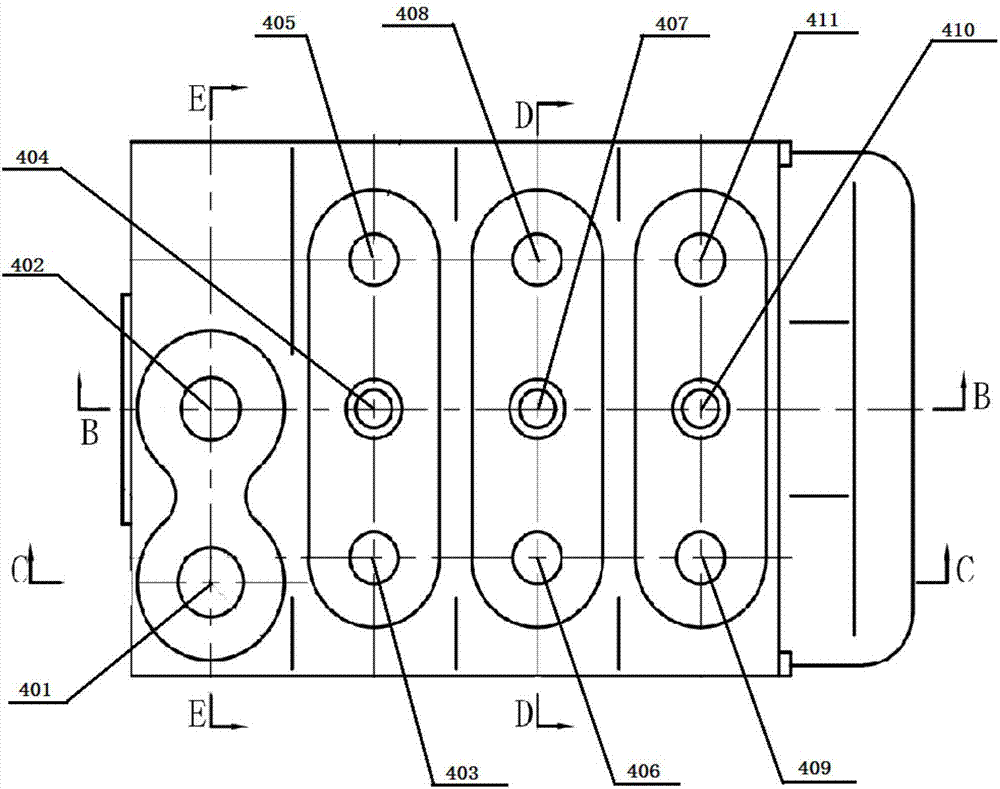

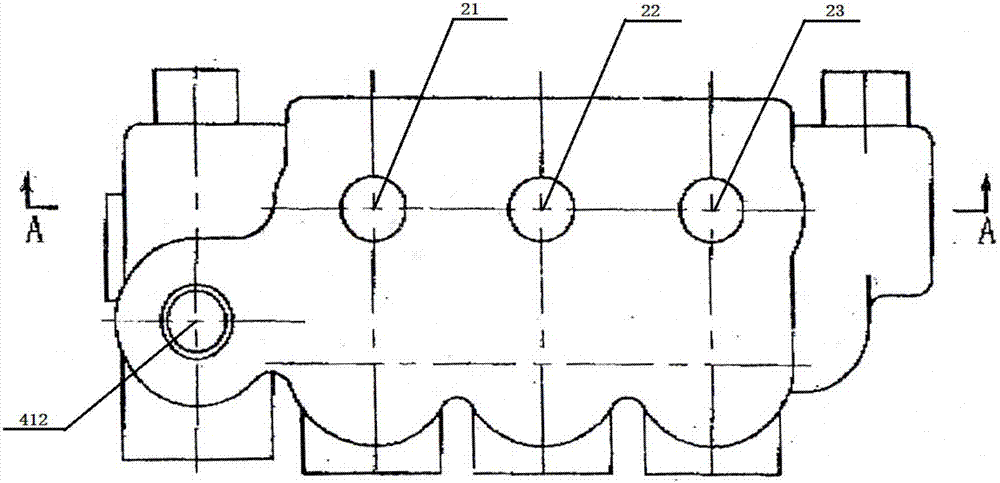

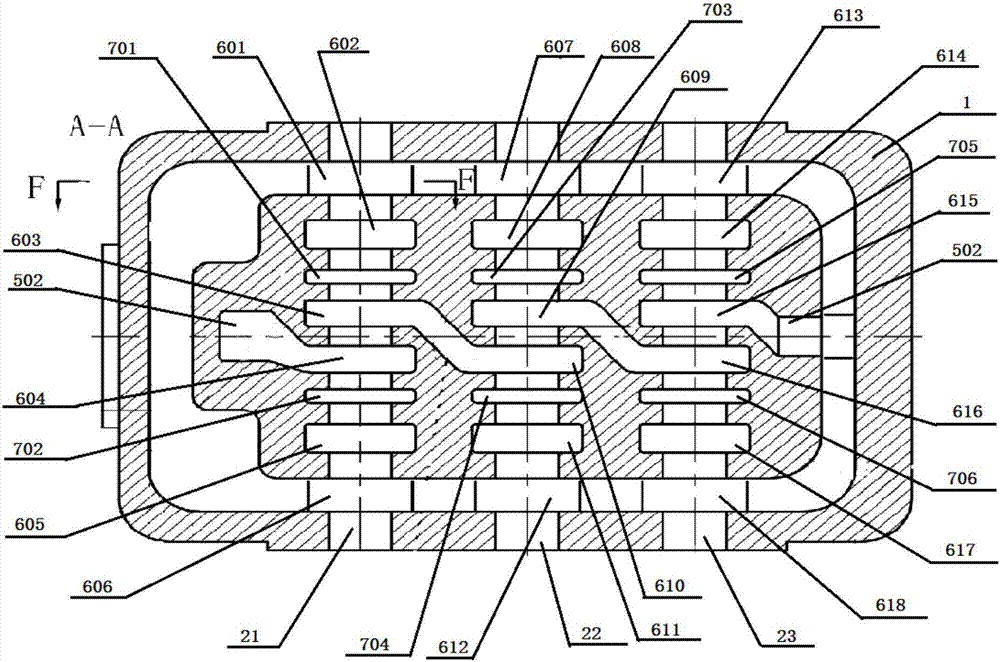

[0055] Such as figure 2 and image 3 As shown, the triple valve body casting includes a valve body 1, and the valve body 1 is internally provided with a valve core through hole, a main flow channel 3, a through hole, an auxiliary flow channel, a circular oil groove and a small circular oil groove, The spool through holes include a first spool through hole 21, a second spool through hole 22 and a third spool through hole 23, the first spool through hole 21, the second spool through hole 22 and the second spool through hole 23. Three spool through holes 23 are arranged in parallel and equidistant and the center of circle is on the same straight line. It is arranged on the through hole of the valve core, the through hole and the auxiliary flow channel. The openings of the through holes are located on each surface of the valve body main body 1 and commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com