Adaptive variable working condition cylindrical spherical pressure bearing system

A cylindrical, variable working condition technology, applied to bearings, shafts and bearings, grain processing, etc., can solve the problems that the static pressure support system cannot form a working oil film, there is no flow compensation adjustment at the oil supply port, and the normal operation of the reducer is affected. , to achieve the effect of reducing the sensitivity of processing precision, reducing the difficulty of processing, and promoting cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

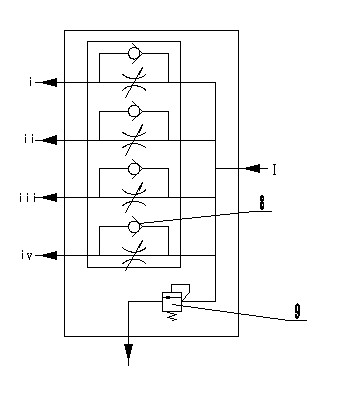

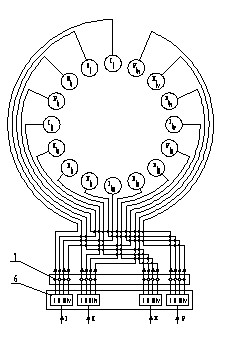

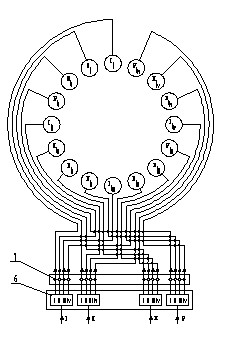

[0015] The present invention comprises 12-16 independent spherical surface pressure bearings, wherein every 4~8 independent spherical surface pressure bearings form a group, such as figure 1 As shown, the self-adaptive variable working condition cylindrical spherical pressure bearing system of the present invention includes 16 independent spherical hydrostatic bearings, wherein every 4 independent spherical hydrostatic bearings form a group, and the spherical hydrostatic bearings in each group share A high-pressure valve block 6, in which each spherical static pressure bearing is connected to the high-pressure valve block 6 through its own independent oil passage, and each oil passage is also provided with a check valve 7, and each group of spherical static pressure bearings is staggered in order Distributed in the same circular plane; see image 3 , one path of high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com