Polymer-coated controlled release pesticide granule and preparation method thereof

A technology for controlled release of pesticides and polymers, applied in fertilizer mixtures, agriculture, fertilization devices, etc., can solve problems such as short duration of action, difficulty in grasping release patterns, and small drug loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

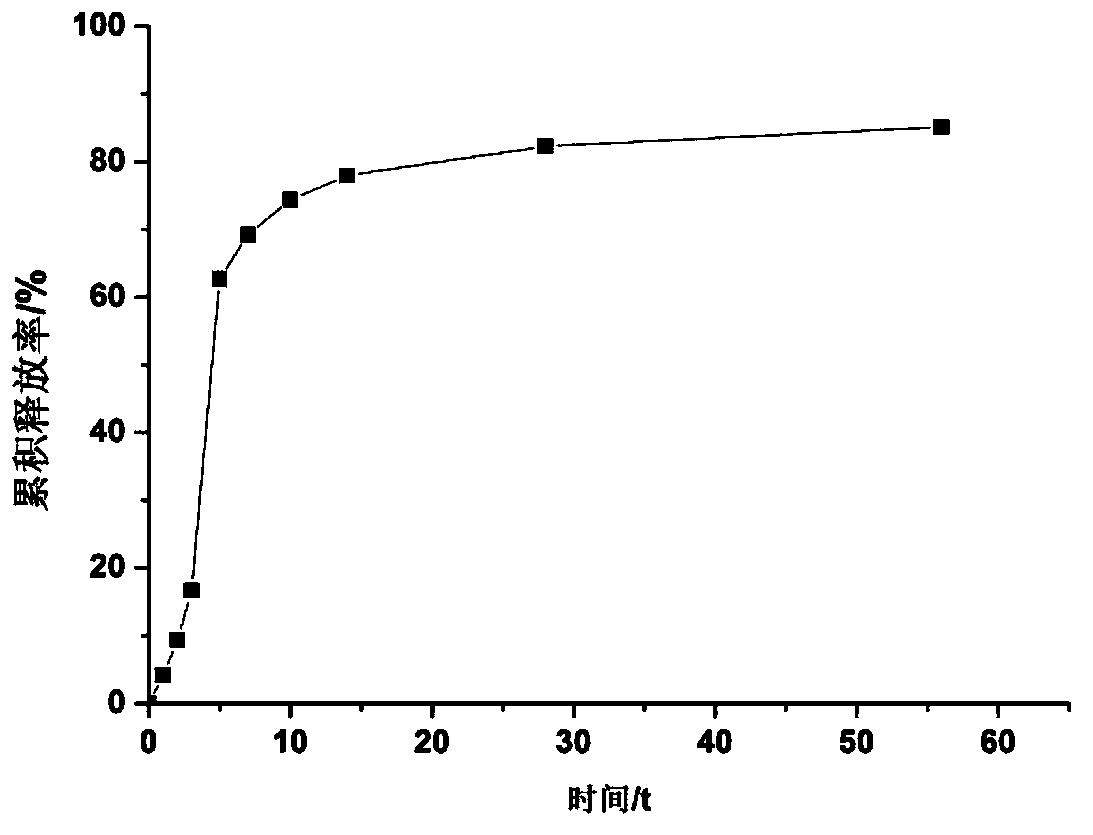

[0078] Weigh 10 kg of self-made pesticide granules with a particle diameter of 3 mm, place them in the drum, turn on the heating switch of the drum, and preheat the fertilizer until the temperature is constant at 85°C. Weigh 100g of toluene diisocyanate (TDI), add 60g of sulfonated paraffin (film-forming agent), and place it in a heating kettle to melt at a constant temperature of 70°C. Weigh 220g of polyether polyol series (Jingzhou Longhua Petroleum Company Type 635), 20g of 1,6-hexanediol (chain extender), add 0.1g of stannous octoate (catalyst), and place it in a heating kettle to melt at constant temperature 80°C. Then open the vent valve of the proportional pump, and then open the pump inlet valve to mix the two-component liquid through the high-efficiency mixer, adjust the pump pressure to 0.1Mpa, and the total spray rate to 0.075L / min, and start spraying. Spray continuously for 6 minutes, until the coating solution is completely sprayed, after 90°C heat preservation r...

Embodiment 2

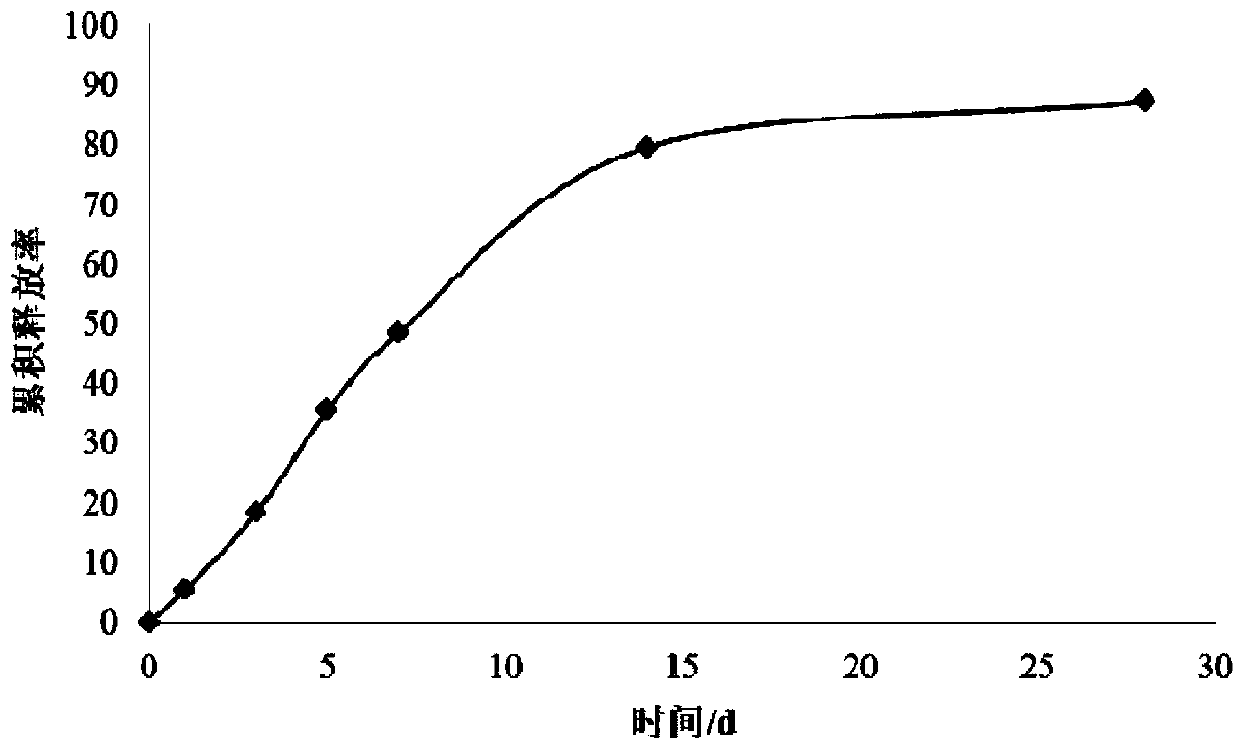

[0087] Add 100 parts of deionized water, 0.5 parts of sodium dodecylsulfonate, and 0.5 parts of OP-10 into the reaction kettle, heat, stir, and protect with nitrogen gas. When the temperature rises to 82°C, mix 100 parts of mixed monomers (methyl methacrylate: ethyl acrylate: hydroxyethyl acrylate: butyl methacrylate in a weight ratio of 45:45:7:3), 0.5 parts Ammonium persulfate was added dropwise to the reactor to initiate polymerization. React for 4 hours to obtain an emulsion polymer, which is cooled for use. 1000g of self-made pesticide granules with a diameter of 4mm were loaded into the fluidized bed and heated to 90°C. Spray castor oil on the surface of the self-made pesticide particles, and the thickness of the sprayed castor oil film is about 5 μm. Then, spray the polymer emulsion on the surface of the granular castor oil layer with a two-fluid nozzle at an atomization pressure of 4kpa at a rate of 2g per minute, and remove the water contained in the film layer afte...

Embodiment 3

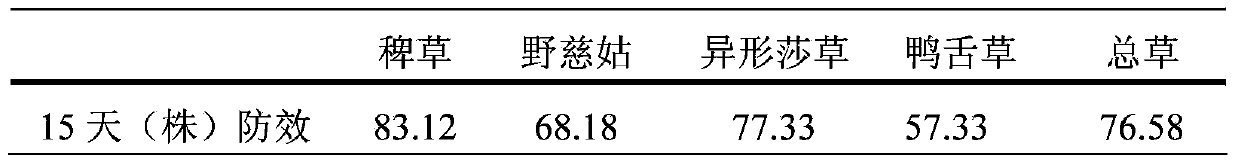

[0095] Weigh 10 kg of self-made pesticide granules with a particle diameter of 3 mm, place them in the drum, turn on the heating switch of the drum, and preheat the self-made pesticide granules until the temperature is constant at 85°C. Weigh 150g of diphenylmethane diisocyanate (MDI), add 60g of paraffin (film-forming agent), and place it in a heating kettle to melt and keep the temperature at 75°C. Weigh 210g of polybutylene adipate and 20g of 2,3-butanediol (chain extender), and place them in a heating kettle to melt at a constant temperature of 90°C. Then open the vent valve of the proportional pump, and then open the pump inlet valve, so that the two-component liquid is mixed through the high-efficiency mixer, adjust the pressure of the pump to 0.1Mpa, and the total spray rate is 0.15 liters / minute, and start spraying. After continuous spraying for 3 minutes, stop spraying, keep warm at 90°C, react for 8 minutes and then cool down to obtain polyurethane-coated controlled-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com