Cold-rolled steel sheet for automobile-seat-adjusting toothed plate produced through precision stamping and manufacturing method of cold-rolled steel sheet

A car seat and precision stamping technology, which is applied in the field of cold-rolled steel plates, can solve the problems of low spheroidization rate, unsuitability for high-speed precision stamping, and low dimensional accuracy, and achieve good performance uniformity, shorten annealing time, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

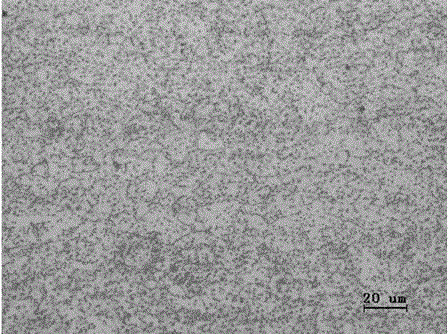

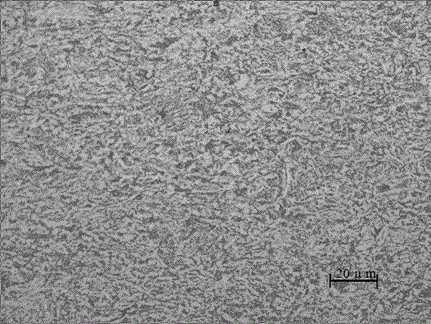

Image

Examples

Embodiment Construction

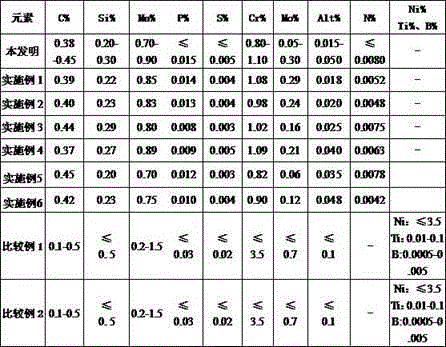

[0047] The present invention will be further described below in conjunction with Examples 1-6 and Comparative Example 1—disclosed in Chinese Patent Application 200780004015.3, and Comparative Example 2—disclosed in Chinese Patent Application 200780004180.9, as shown in Tables 1 to 4.

[0048] Table 1 Chemical composition of the present invention (% by weight), the balance is Fe and unavoidable impurities.

[0049]

[0050] According to the requirements of the material composition design of the present invention, pre-desulfurization of molten iron is adopted, combined blowing at the top and bottom of the converter, bottom blowing of Ar at the Ar blowing station (or LF furnace temperature rise) ensures that the stirring time is longer than 5 minutes, fine-tuning of the composition of the RH furnace, and vacuum cycle degassing Treatment, to ensure that the RH pure degassing time is greater than 15 minutes, and at the same time feed an appropriate amount of iron-calcium wire, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com