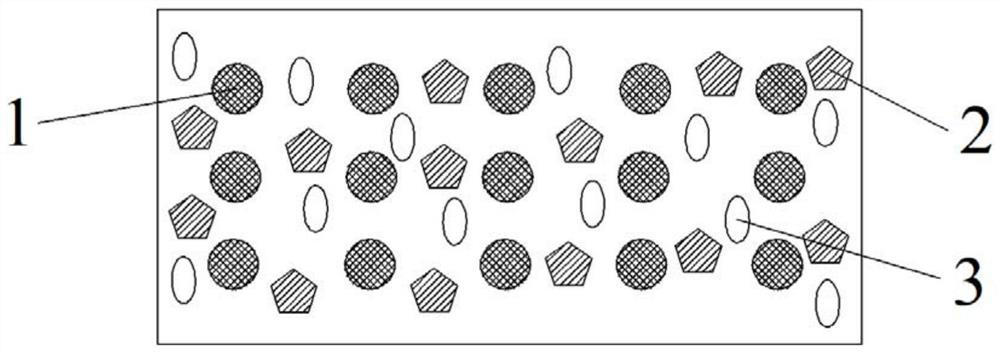

Magnetorheological elastomer as well as preparation method and application thereof

A magnetorheological elastomer and magnetic particle technology, applied in the field of ultra-precision polishing, can solve the problems of inability to achieve ultra-precision grinding and polishing of material surfaces, and subsurface damage of material surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

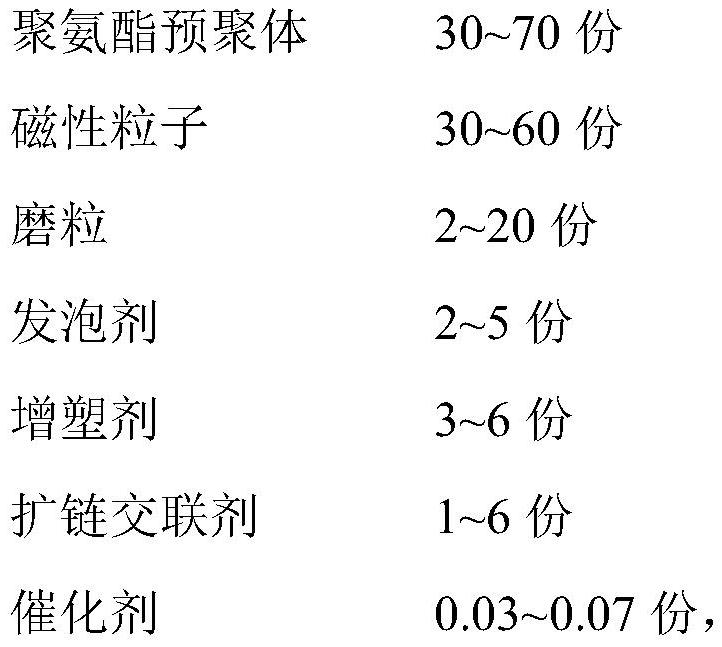

[0076] A magnetorheological elastomer, by weight fraction, includes the following components: polyurethane prepolymer, magnetic particles, abrasive grains, foaming agent, plasticizer, chain extension crosslinking agent, catalyst, wherein each component The specific content is shown in Table 1 below.

[0077] Table 1: Composition of magnetorheological elastomers in Examples 1-5

[0078] raw material Example 1 Example 2 Example 3 Example 4 Example 5 Polyurethane prepolymer 40 30 70 50 40 magnetic particles 50 60 30 40 60 Abrasive grains 5 2 20 10 5 Foaming agent 3 2 5 4 5 plasticizer 4 6 3 5 6 chain extender 5 1 6 1.3 1.3 catalyst 0.04 0.03 0.07 0.05 0.04

[0079]Wherein, the magnetic particles are carbonyl iron powder, and the particle diameter of the magnetic particles is 3 μm. The polyurethane prepolymer is polytetramethylene glycol (PTMG), the abrasive grain is diamond, and the par...

Embodiment 6

[0088] A kind of magnetorheological elastomer, different from embodiment 1 is:

[0089] The particle diameter of the magnetic particles was 1 μm.

[0090] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 7

[0092] A kind of magnetorheological elastomer, different from embodiment 1 is:

[0093] The particle diameter of the magnetic particles was 7 μm.

[0094] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com