A kind of high temperature resistant magnetorheological fluid and preparation method thereof

A technology of magnetorheological fluid and high temperature resistance, which is applied in the direction of magnetic fluid, magnetic materials, magnetic objects, etc., and can solve the problems affecting the performance and control of the rheological characteristics of magnetorheological fluid, the decrease of yield stress, and the change of magnetorheological fluid composition and other problems, to achieve the effect of excellent magnetorheological properties, low thermal expansion coefficient and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

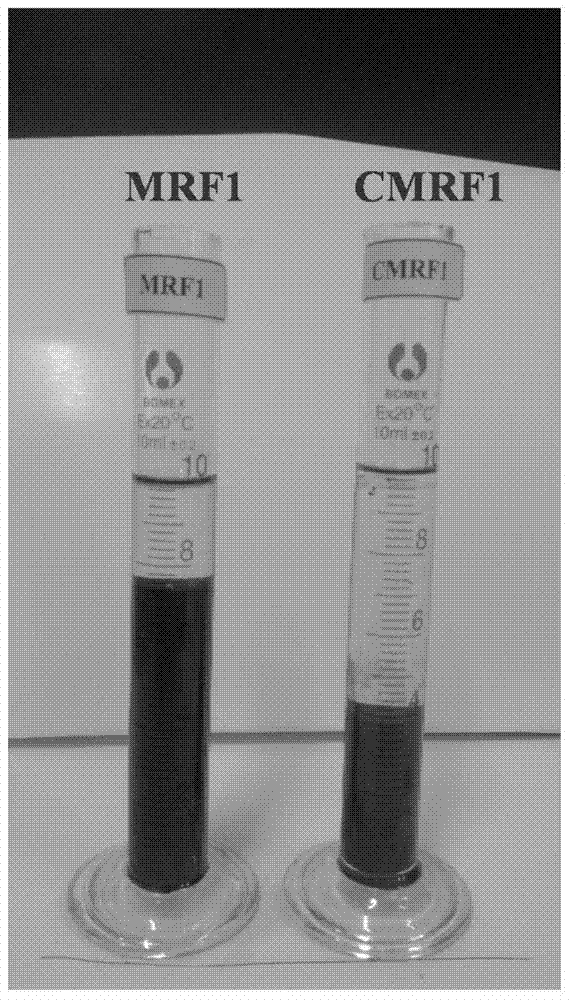

Image

Examples

Embodiment 1

[0031] A high-temperature-resistant magnetorheological fluid is prepared by the following method:

[0032] (1) 10g (6.7%) molecular weight is that sulfonated polystyrene (SPS) of 100~200KDa, sulfonation degree is 20% is dissolved in the THF of 50g (33.3%), then NaOH solution is added dropwise to adjust the mixed solution pH=9~10, after fully stirring evenly, add 90g (60%) carbonyl iron powder micron particles with an average particle size of 30um to it, keep stirring and react at 20°C for 50h under the protection of nitrogen, after the reaction, magnetically separate the modified particles, wash the modified particles with ethanol three times, and vacuum-dry them at 60°C for 12 hours to become sulfonated polystyrene-modified carbonyl ferromagnetic particles;

[0033] (2) 1.0g (1.0%) molecular weight is that sulfonated polystyrene (SPS) of 100~200KDa, sulfonation degree is 20%, 1g (1%) antioxidant N-phenyl-α-naphthylamine, Add 1g (1%) anti-wear agent zinc dialkyl dithiophospha...

Embodiment 2

[0038] A high-temperature-resistant magnetorheological fluid is prepared by the following method:

[0039] (1) Dissolve 6g (4.6%) of sulfonated polystyrene (SPS) with a molecular weight of 100-200KDa and a sulfonation degree of 30% in 30g (23.1%) of tetrahydrofuran, and then dropwise add 0.5mol / L of NaOH The solution adjusts the pH of the mixed solution to 11 to 12. After fully stirring, add 94g (72.3%) ferric oxide micron particles with an average particle diameter of 15um, keep stirring and react at 30°C under nitrogen protection. After 10 hours of reaction, the modified particles were magnetically separated, the modified particles were washed with ethanol three times, and vacuum-dried at 60°C for 12 hours, they were sulfonated polystyrene-modified ferric oxide micron magnetic particles;

[0040] (2) sulfonated polystyrene (SPS) that 10g (10%) molecular weight is 100~200KDa, sulfonation degree is 30%, 2g (2%) antioxidant diphenylamine, 2g (2%) antiwear agent Di-n-butyl phos...

Embodiment 3

[0046] A high-temperature-resistant magnetorheological fluid is prepared by the following method:

[0047] (1) Dissolve 4g (3.2%) of sulfonated polystyrene (SPS) with a molecular weight of 100-200KDa and a sulfonation degree of 40% in 25g (20%) of tetrahydrofuran, and then dropwise add 0.5mol / L of NaOH The solution adjusts the pH of the mixed solution to 10 to 11. After fully stirring evenly, add 96g (76.8%) of iron oxide microparticles with an average particle diameter of 10um, keep stirring and react at 25°C for 24h under nitrogen protection. After the reaction, the modified particles are magnetically separated, the modified particles are washed with ethanol three times, and vacuum-dried at 60° C. for 12 hours, they become sulfonated polystyrene-modified iron oxide micron magnetic particles;

[0048] (2) 2g (2%) sulfonated polystyrene (SPS) with a molecular weight of 100-200KDa and a sulfonation degree of 40%, 2g (2%) antioxidant N, N-di-sec-butyl-terephthalene Amine, 1g (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com