Process method for extracting aluminum oxide in coal ash of pulverized coal furnace by using acid method

A process method, fly ash technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of difficult extraction of alumina, and achieve the effect of easy roasting operation, industrial production, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

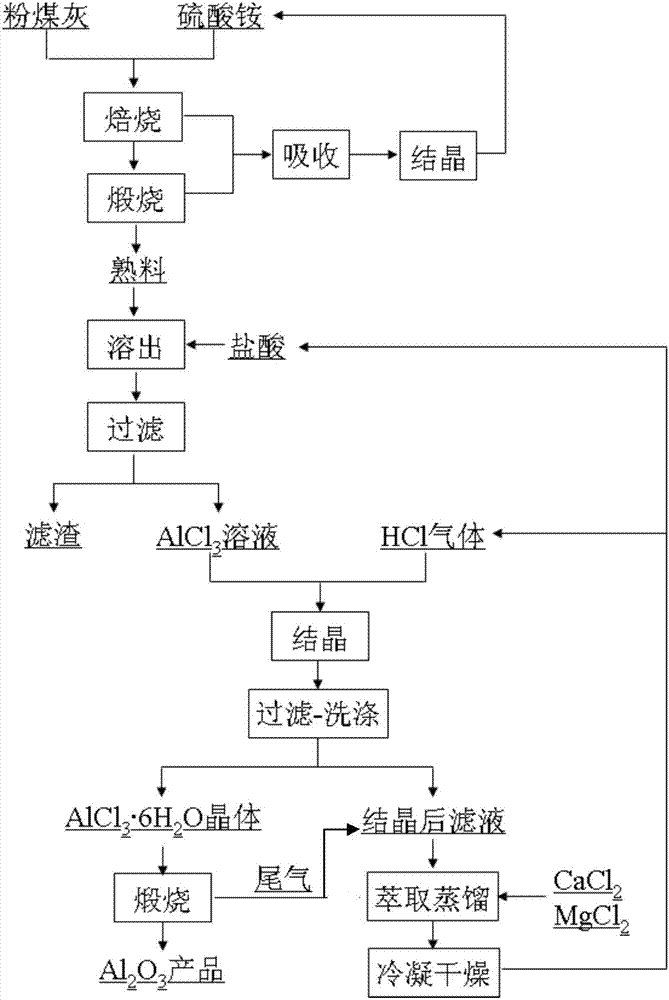

Image

Examples

Embodiment 1

[0037] 2.00kg fly ash (containing 52.00% Al 2 o 3 , 37.27% SiO 2 ) and 4.04kg ammonium sulfate (Al 2 o 3 Mixed evenly with ammonium sulfate (molar ratio 1:3), roasted in a roasting furnace at 300°C for 0.5h, then raised the temperature to 600°C for 0.5h to obtain fly ash clinker. Take 2.00kg of clinker, add 6.00kg of 20% hydrochloric acid solution to the 2.00kg of clinker, carry out dissolution reaction at 90°C for 0.5h, filter to achieve solid-liquid separation, and wash the filter residue with 1.00kg of water. Take 8.60kg of filtrate and feed it with HCl gas under stirring, control the solution temperature to be 20°C, stop the ventilation when the concentration of hydrochloric acid in the solution reaches 36%, leave it to age for 1h, filter and separate, and wash with 2.00kg of concentrated hydrochloric acid (37%) Aluminum chloride hexahydrate crystals were obtained after crystallization, and the crystals were calcined at 900°C for 0.5h to obtain 0.88kg of alumina, with ...

Embodiment 2

[0039] 2.00kg fly ash (containing 52.00% Al 2 o 3 , 37.27% SiO 2 ) and 6.06kg ammonium sulfate (Al 2 o 3 Mix evenly with ammonium sulfate (mole ratio 1:6), roast in a roasting furnace at 410°C for 1.5h, then raise the temperature to 750°C and continue calcining for 2h to obtain fly ash clinker. Take 2.00kg of clinker, add 14.00kg of 30% hydrochloric acid solution to the 2.00kg of clinker, carry out dissolution reaction at 140°C for 1.5h, filter and separate, and wash the filter residue with 2.00kg of water. Take 17.60kg of filtrate and feed it with HCl gas under stirring, control the solution temperature to be 30°C, when the concentration of hydrochloric acid in the solution reaches 38%, stop the aeration, leave it to age for 5 hours, filter and separate, wash with 3kg of concentrated hydrochloric acid (37%) Aluminum chloride hexahydrate crystals were obtained, and the crystals were calcined at 1100° C. for 1.5 h to obtain 0.93 kg of alumina, with an extraction rate of 89....

Embodiment 3

[0041] 2.00kg fly ash (containing Al 2 o 3 52.00%, SiO 2 37.27%) and 8.08kg ammonium sulfate (Al 2 o 3 Mix evenly with ammonium sulfate (molar ratio 1:8), roast in a roaster at 500°C for 3h, then raise the temperature to 900°C and continue calcining for 5h to obtain fly ash clinker. Take 2.00kg of clinker, add 20.00kg of 35% hydrochloric acid solution to the 2.00kg of clinker, carry out dissolution reaction at 150°C for 3 hours, filter and separate, and wash the filter residue with 4.00kg of water. Take 25.6kg of filtrate and feed it with HCl gas under stirring, control the solution temperature to 45°C, stop ventilation when the concentration of hydrochloric acid in the solution reaches 40%, leave it to age for 10 hours, filter and separate, wash with 6kg of concentrated hydrochloric acid (37%) Aluminum chloride hexahydrate crystals were obtained, and the crystals were calcined at 1200° C. for 3 hours to obtain 0.94 kg of alumina, with an extraction rate of 90.4%. The chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com