Special device for producing micro glass beads by molten glass discarded liquid

A technology of glass microbeads and special devices, which is applied in glass production, glass forming, glass manufacturing equipment, etc., to achieve the effect of increasing production capacity, good prospects and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

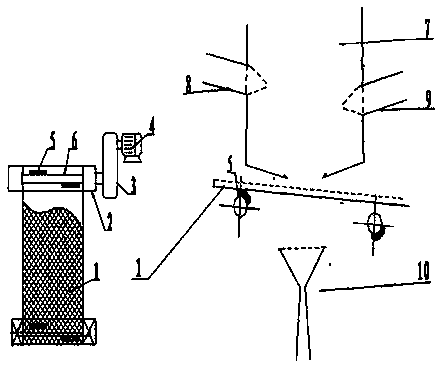

[0008] Combine below figure 1 , The implementation process of the present invention is described.

[0009] The implementation process of the present invention is very simple: the melt outlet 8 and the high-pressure air nozzle group 9 are all installed in the granulation barrel 7, and the installation angle of each nozzle in the high-pressure air nozzle group 9 can be within the xyz of the granulation barrel 7. The space can be adjusted arbitrarily. Its function is to finely granulate the molten material discharged from the molten liquid outlet 8. After the granulated molten material rotates into beads in the granulating barrel 7, it settles into the vibrating screen 1 for sieving. After obtaining the product, the effect of the sieve cleaning nozzle 10 is to spray water to clean the sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com