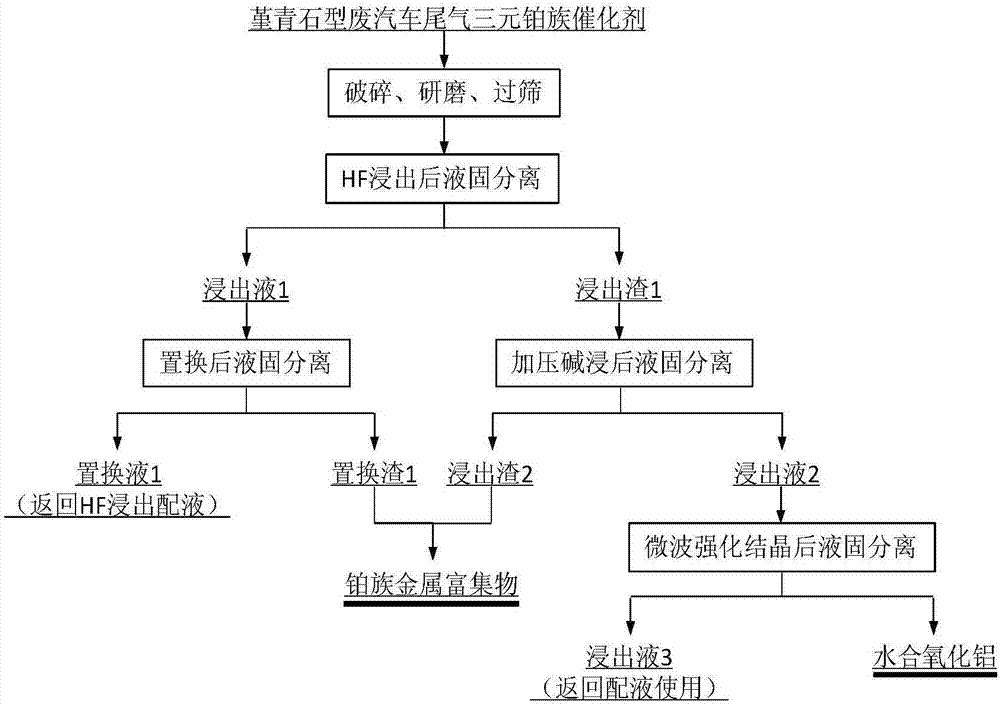

Rough extraction method for cordierite type waste automobile tail gas three-way catalyst

A three-way catalyst, automobile exhaust technology, applied in the field of comprehensive recycling and utilization of resource regeneration, can solve the problems of large differences in the degree of oxidation of active components, dispersion and loss of resources, environmental pollution in the process of resource recovery and treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The cordierite-type waste automobile exhaust three-way catalyst provided by a company in Gansu is mainly composed of: SiO 2 31.6%, Al 2 O 3 39.1%, Pt 245g / t, Pd 1480g / t, Rh 185g / t. First, crush, grind, and pass through a nylon standard sieve to make the particle size ≤200 mesh.

[0029] Take 100g of the above-mentioned waste automobile exhaust three-way catalyst fine powder and 200ml of HF solution for mixing and leaching. The amount of HF in the solution during leaching is that Si and Al in the fine powder are all leached into SiF 4 ,AlF 3 0.2 times the theoretical amount required, the leaching temperature is 30°C, and liquid-solid separation after 60 minutes of reaction. Wash the leached residue with 20ml of tap water, combine the washing water with the filtrate, and dry the leached residue. Finally, 206 ml of filtrate (leaching solution 1) and 84.2 g of leaching residue (leaching residue 1) are obtained. 0.01g copper powder was added to the leachate 1, and the replac...

Embodiment 2

[0031] Take the composition as in Example 1 of the waste automobile exhaust three-way catalyst 500g. Firstly, it is broken, ground, and passed through a nylon standard sieve to make the particle size ≤200 mesh.

[0032] Take the above-mentioned waste automobile exhaust three-way catalyst fine powder and 1500ml of HF solution for mixing and leaching. The amount of HF in the solution during leaching is that Si and Al in the fine powder are all leached into SiF 4 ,AlF 3 0.3 times the theoretical amount required, the leaching temperature is 20°C, and the liquid and solid are separated after 60 minutes of reaction. Wash the leaching residue with 100ml tap water, combine the washing water with the filtrate, and dry the leaching residue. Finally, 1571 ml of filtrate (leaching solution 1) and 388 g of leaching residue (leaching residue 1) are obtained. 0.06g nickel powder was added to the leachate 1, and the replacement treatment was carried out at 40°C for 40 minutes. After the replac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com