A method for recycle that electrolyte of waste battery

An electrolyte recycling and waste technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of low crystallization efficiency, high electrolyte viscosity, decomposition of lithium hexafluorophosphate, etc., to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

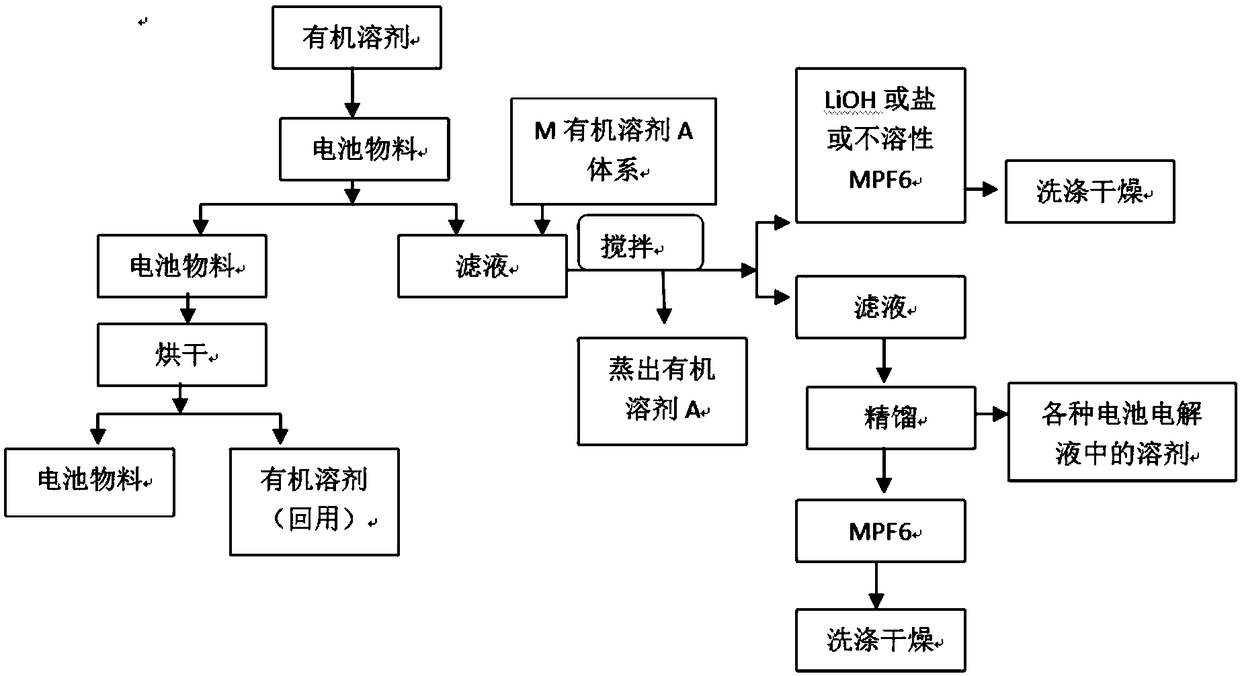

[0032] Firstly, the crushed battery materials are leached in stages using an organic solvent. The organic solvent is dimethyl carbonate, and the electrolyte in the battery is completely leached, and then a clarified leaching solution is obtained by settling and filtering.

[0033] The battery material is dried by heating, and the evaporated organic solvent is collected for recycling. The dried battery materials are used for the extraction of active substances in the next step.

[0034] The filtrate was transferred to a crystallization kettle, and a saturated ethanol solution of potassium hydroxide was added dropwise at 25°C, and stirred to convert lithium hexafluorophosphate in the filtrate into potassium hexafluorophosphate and lithium hydroxide. The ethanol in the reaction system was distilled off under reduced pressure, and LiOH and part of potassium hexafluorophosphate crystals were precipitated, filtered, washed with dimethyl carbonate, and dried to obtain lithium hydroxi...

Embodiment 2

[0037] Firstly, the crushed battery materials are leached by grade with an organic solvent. The organic solvent is selected from ethylene glycol dimethyl ether, and the electrolyte in the battery is completely leached, and then a clarified leaching solution is obtained by sedimentation and filtration.

[0038] The battery material is dried by heating, and the evaporated organic solvent is collected for recycling. The dried battery materials are used for the extraction of active substances in the next step.

[0039] Transfer the filtrate to a crystallization kettle, add a saturated methanol solution of sodium chloride dropwise at 25°C, and stir to convert the lithium hexafluorophosphate in the filtrate into sodium hexafluorophosphate and lithium chloride. The methanol in the reaction system was distilled off under reduced pressure, then lithium chloride and part of the crystals of sodium hexafluorophosphate were precipitated, filtered, washed with dimethyl carbonate, and dried ...

Embodiment 3

[0042] Firstly, the crushed battery materials are leached in stages using an organic solvent. The organic solvent is acetone, and the electrolyte in the battery is completely leached, and then a clarified leaching solution is obtained by settling and filtering.

[0043] The battery material is dried by heating, and the evaporated organic solvent is collected for recycling. The dried battery materials are used for the extraction of active substances in the next step.

[0044] Transfer the filtrate to a crystallization kettle, add a saturated ethanol solution of ammonium chloride dropwise at 25°C, and stir to convert the lithium hexafluorophosphate in the filtrate into ammonium hexafluorophosphate and lithium chloride. The ethanol in the reaction system was distilled off under reduced pressure, and lithium chloride crystals were precipitated, which were filtered, washed with dimethyl carbonate, and dried to obtain lithium chloride crystals.

[0045] Then through rectification u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com