Patents

Literature

34results about How to "Environmentally friendly and efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

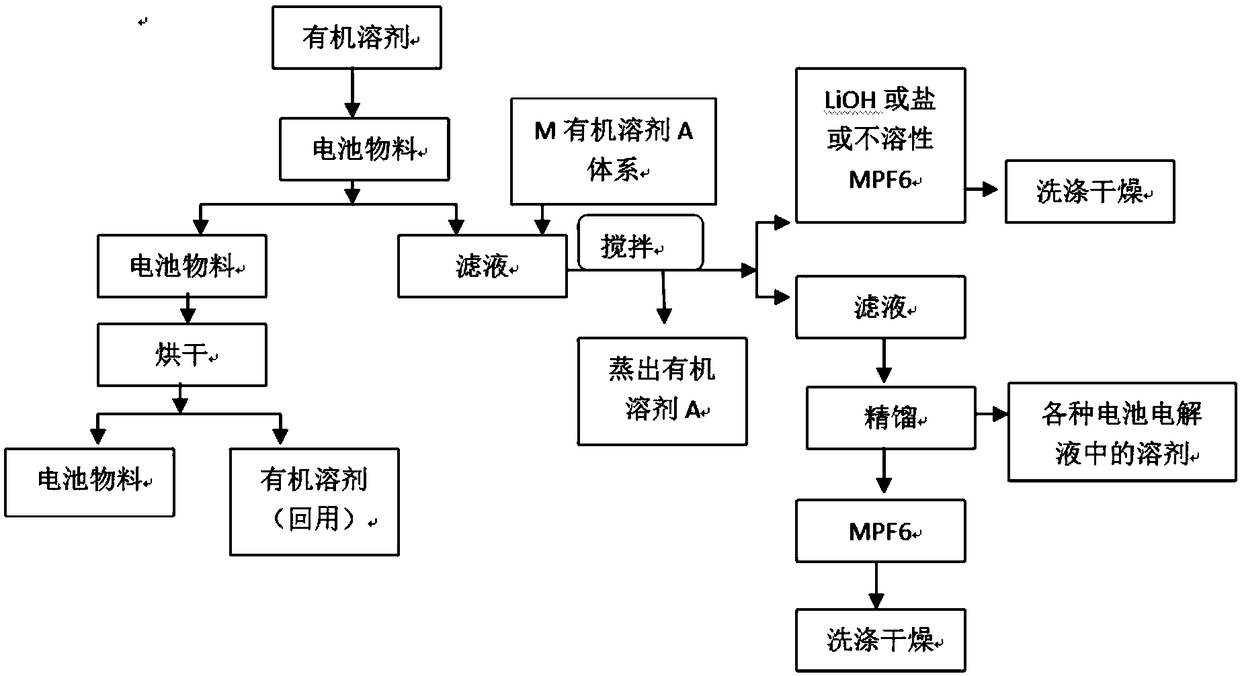

A method for recycle that electrolyte of waste battery

ActiveCN109193062AAchieve recyclingRealize full recyclingWaste accumulators reclaimingBattery recyclingSolventPotassium ions

A method for recover and utilizing waste power battery electrolyte includes leaching crushed battery material with organic leaching solvent, filter after leaching to obtain clarified leaching solutionand filter residue, recovering electrolyte from crushed battery material with organic leaching solvent, recovering electrolyte from crushed battery material with organic leaching solvent, recoveringelectrolyte from crushed battery material with organic leaching solvent. Dropping an organic solvent A solution of a potassium ion compound or a metal ion compound into the leaching solution until thereaction is completed to obtain a reaction mixture; Separating an organic solvent A in the reaction mixture, and filtering to obtain a filtrate and crystals of lithium hydroxide or lithium salt; Separating the organic solvent from the filtrate to obtain potassium hexafluorophosphate or other hexafluorophosphate crystals. The invention fully considers the composition of the electrolyte and the physico-chemical characteristics of the electrolyte lithium hexafluorophosphate, by introducing the solvent leaching-lithium hexafluorophosphate conversion-rectification separation technology and the like, the recycling of electrolyte in waste batteries is realized. The technical process can realize the full recovery of electrolyte without any discharge and has the advantages of environmental protection and high efficiency.

Owner:山西根复科技有限公司

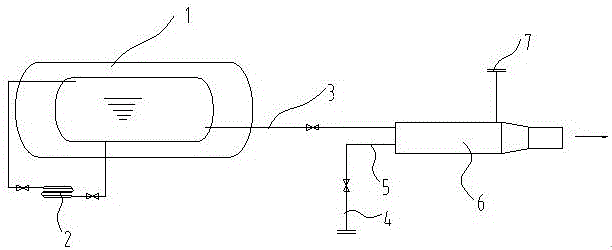

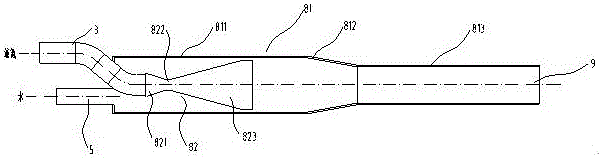

Fire fighting method, fire fighting system and fire fighting truck with fire fighting system

The invention relates to a fire fighting method, a fire fighting system and a fire fighting truck with the fire fighting system. The fire fighting method comprises the following steps: absorbing heat by liquid nitrogen flow in a mixer and then gasifying at least part of liquid nitrogen flow into nitrogen gas flow; after striking the nitrogen gas flow with water at high speed, forming a mixture of nitrogen gas and water mist; jetting the mixture of nitrogen gas and water mist to a fire source through a jetting port of the mixer and forming cloudy isolation nearby the fire source; isolating oxygen and reducing the temperature at the fire source, thereby achieving the purpose of fire fighting. According to the invention, the liquid nitrogen and water are mixed and then the mixture of nitrogen gas and water mist is outward jetted; the mist mixture is coated on the fire source; on one hand, the water mist absorbs heat and then is quickly gasified; on the other hand, the nitrogen gas is quickly coated on the fire source; the oxidizing reaction speed in combustion is restrained; the oxygen is effectively isolated; the fire fighting method has dual functions and advantages of water spraying and inert gas fire-fighting; after use, the environment in the place of the fire source is not polluted; the method has the advantages of environmental protection and high efficiency.

Owner:SHANDONG HONGDA TECH GRP

Aluminium zinc phosphomolybdate compounded rustproof pigment and production method thereof

ActiveCN101864214ANon-toxicEnvironmentally friendly and efficientAnti-corrosive paintsPhosphorus compoundsPhosphomolybdic acidZinc phosphate

The invention provides an aluminium zinc phosphomolybdate compounded rustproof pigment which takes aluminium zinc phosphate, zinc molybdate, aluminium phosphate and the like as main raw materials to synthesise aluminium zinc phosphomolybdate compounded rustproof pigment. The rustproof pigment is prepared from the following raw materials in parts by weight: 50-75 parts of aluminium zinc phosphomolybdate, 10-20 parts of aluminium phosphate, 3-10 parts of zinc oxide, 1-8 parts of barium sulphate, 0.5-5 parts of zinc molybdate and 0.1-0.5 part of accessory ingredient. The preparation method comprises the following steps: (1) after a certain quantity of water is added into an agitated reactor, successively adding the aluminium zinc phosphate, aluminium phosphate and zinc molybdate into an agitated reactor under the condition of stirring, stirring at the temperature of 50-100 DEG C; (2) fully stirring the materials with barium sulfate and zinc oxide, and carrying out modified treatment; (3) cooling the materials to be below 50 DEG C, and adding the accessory ingredient to carry out surface treatment; and (4) carrying out centrifugal dehydration, drying, smashing, weighting and packaging into products. The invention has the characteristics of no toxin, environment protection and high efficiency of the rustproof pigment and can completely replace the traditional toxic heavy metal rustproof pigment, such as red lead, zinc chrome and the like in the industrial pigment.

Owner:GUANGXI XINJING TECH

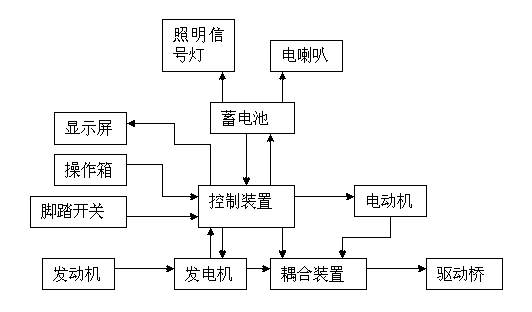

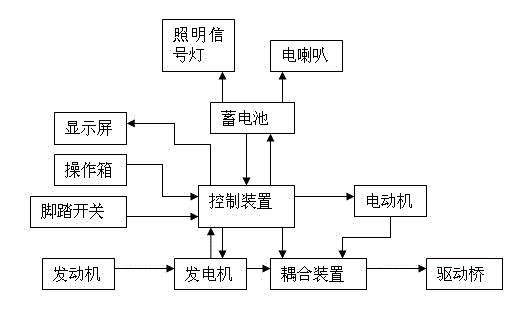

Driving system for mining hybrid power trackless rubber-tyred vehicle

ActiveCN103009991AEnvironmentally friendly and efficientPower footGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectricityCoupling

The invention discloses a driving system for a mining hybrid power trackless rubber-tyred vehicle, belonging to the technical field of driving devices. The driving system comprises an engine, a generator, a storage battery, an illumination signal lamp, an electric horn, a display screen, an operation box, a pedal switch, a control device and a motor, wherein the engine is electrically connected with the generator, the illumination signal lamp and the electric horn are electrically connected with the storage battery, the generator, the operation box, the pedal switch, the display screen, the storage battery and the motor are all electrically connected with the control device. The driving system is characterized by further comprising a coupling device, wherein the generator, the control device and the motor are electrically connected with the coupling device, and the coupling device is electrically connected with the driving axle of the trackless rubber-tyred vehicle. The driving system has the beneficial effects that as the driving system for the hybrid power trackless rubber-tyred vehicle is jointly driven by the engine and the storage battery, the driving system has the advantages of the sufficient power and the strong endurance capability of a diesel engine as well as the environment protection, high efficiency and the flexibility of the storage battery, and multiple operational modes of the driving system are suitable for complex road situations under a shaft.

Owner:CHINA UNIV OF MINING & TECH

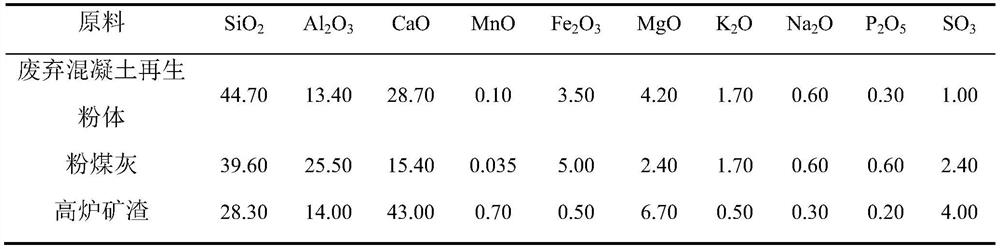

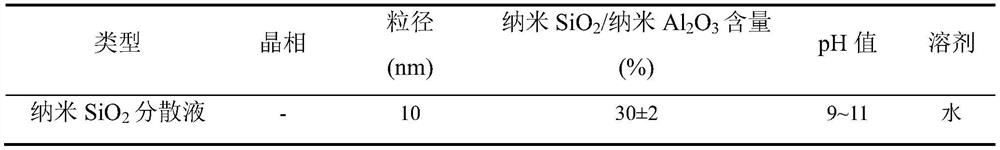

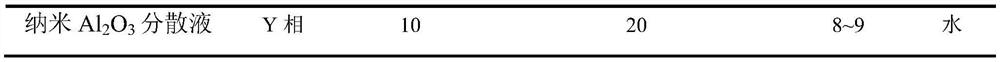

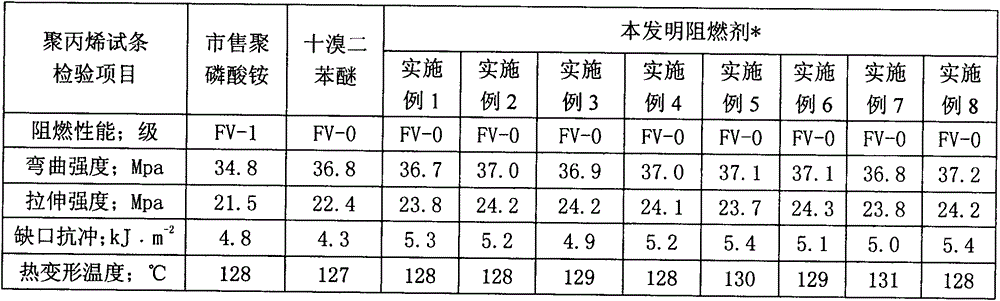

Modified high-strength geopolymer cementing material and preparation method thereof

The invention relates to a modified high-strength geopolymer cementing material and a preparation method thereof. The geopolymer cementing material is prepared by using waste concrete regenerated powder, blast furnace slag and fly ash as precursors, using a nano SiO2 aqueous dispersion or a nano Al2O3 aqueous dispersion for modification, and using a mixed solution of a sodium silicate solution and sodium hydroxide as an alkali activator. The waste powder generated in the waste concrete recycling process is consumed to prepare the geopolymer cementing material with high strength under the normal-temperature curing condition. The geopolymer cementing material is a green building material, and has the advantages of being high in early strength, excellent in durability and the like. High-added-value utilization of the waste concrete powder is achieved. The preparation method is also simple and easy to operate and has a wide application prospect.

Owner:SOUTHEAST UNIV

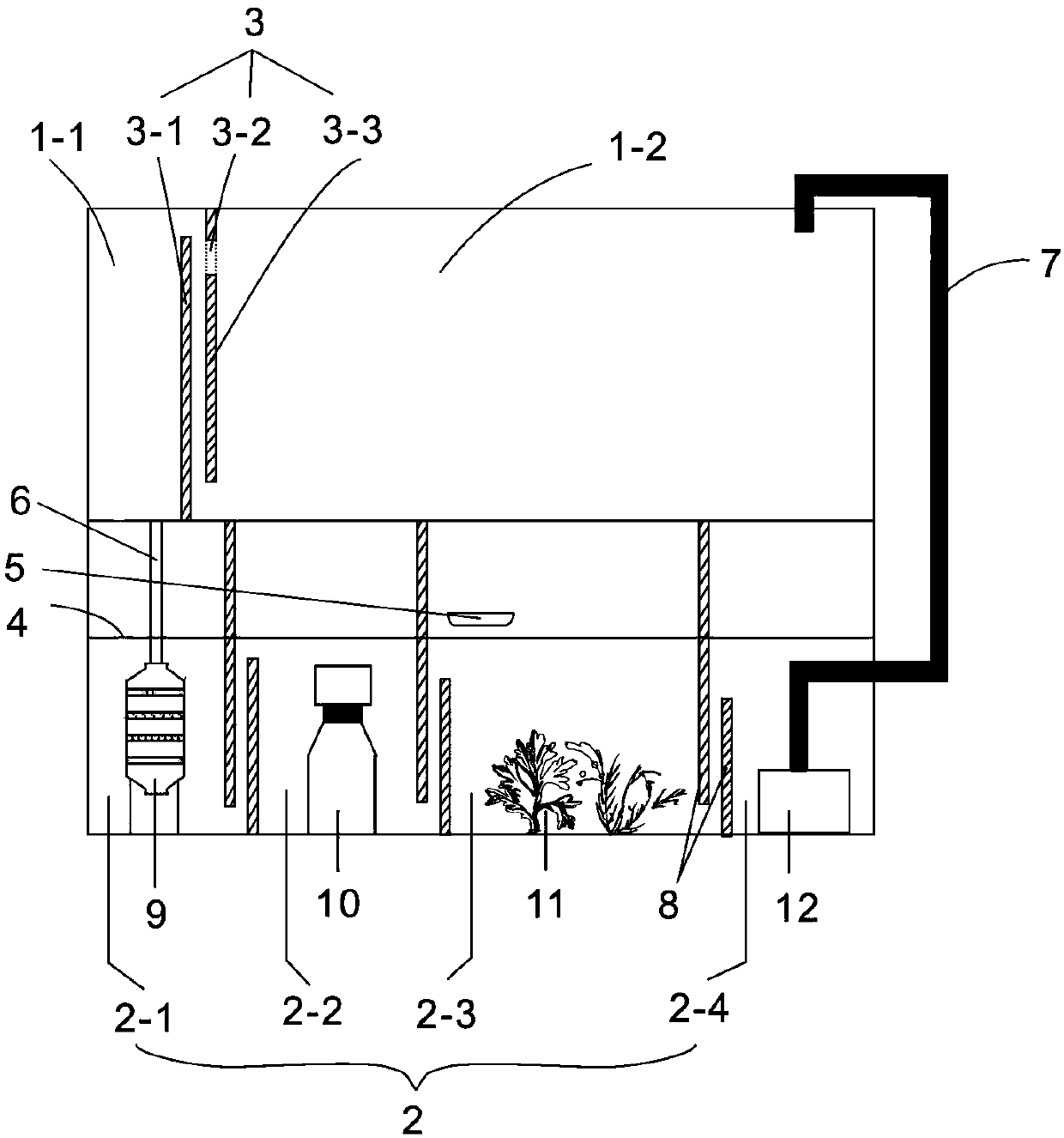

Fish tank for breeding marine organisms

InactiveCN107711677ASuitable for farmingPurifies the water quality effect is goodPisciculture and aquariaFiltrationMaster cylinder

The invention discloses a fish tank for cultivating marine organisms. It is designed in the field of fish tanks and includes a main tank and a bottom tank arranged below the main tank. The main tank and the bottom tank are sealed and connected by glue. It is divided into breeding area and water area. There are 3 combined overflow tanks inside the sump tank. The combined overflow tank divides the inside of the sump tank from left to right into filtration area, protein separation area, algae tank area and upper water area. The water area is connected to the main tank through the upper water pipe, the water pump in the upper water area is connected to the upper water pipe, the bottom of the lower water area is provided with a lower water pipe connected to the filter area, the lower water pipe is connected to the filter device, and the filter device is erected at the bottom of the sump Above the bottom cylinder, there is a window on one side, and a handle is arranged on the window, and the window opens and closes outwards. The opening of the window is higher than the overflow port of the combined overflow tank. The present invention is Farmed marine life enthusiast.

Owner:CHENGDU KECHUANGCHENG TECH

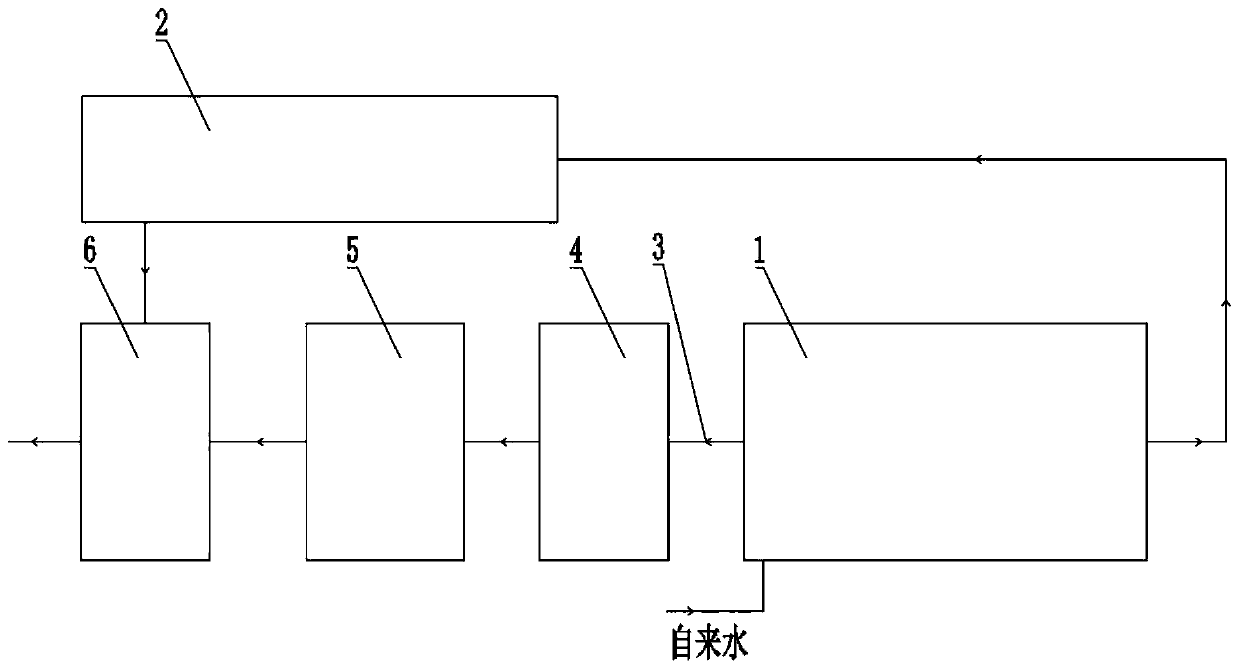

Industrial water treatment system

InactiveCN110759569ALower requirementTroubleshoot usage issuesWater/sewage treatment by irradiationSpecific water treatment objectivesWater useActivated carbon filtration

The invention provides an industrial water treatment system. The industrial water treatment system comprises water treatment equipment, wherein the water treatment equipment is in pipeline connectionwith a water using part and a tap water pipe; the water using part is in pipeline connection with sewage treatment equipment; the water treatment equipment is connected with a concentrated water tank;the concentrated water tank is in pipeline connection with a boiler; the boiler is in pipeline connection with the sewage treatment equipment; the water treatment equipment comprises a raw water tank; the raw water tank is connected with a flocculant dosing device; the dosing device is in pipeline connection with a quartz sand filter; the quartz sand filter is in pipeline connection with an activated carbon filter; the activated carbon filter is in pipeline connection with a water softener; the water softener is in pipeline connection with a soft water tank; the soft water tank is in pipelineconnection with a first reverse osmosis device; the first reverse osmosis device is connected with an intermediate water tank; the intermediate water tank is in pipeline connection with a second reverse osmosis device; a second reverse osmosis membrane stack is connected with a pure water tank; and the pure water tank is fixedly connected with the water using part. The industrial water treatmentsystem has the advantages that wastewater can be utilized, the treatment resources are reduced, the water purification effect is good, and the system is more suitable for the needs of users.

Owner:秦皇岛艾科晟科技有限公司

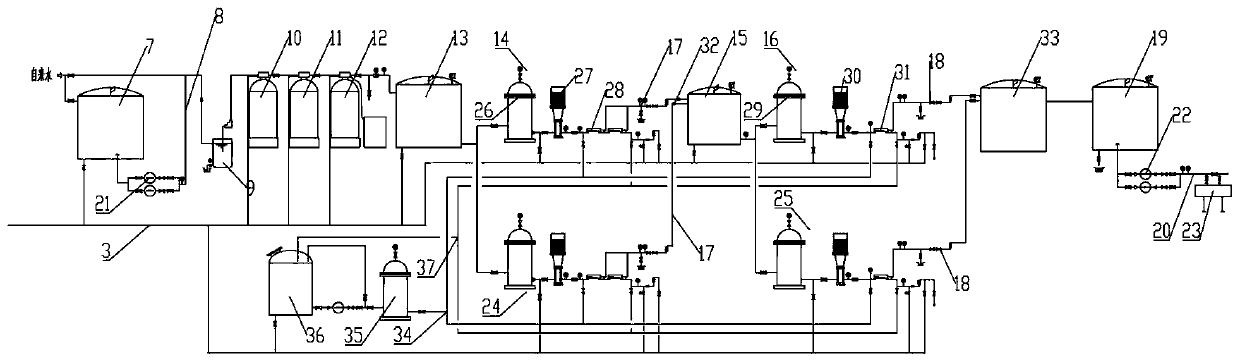

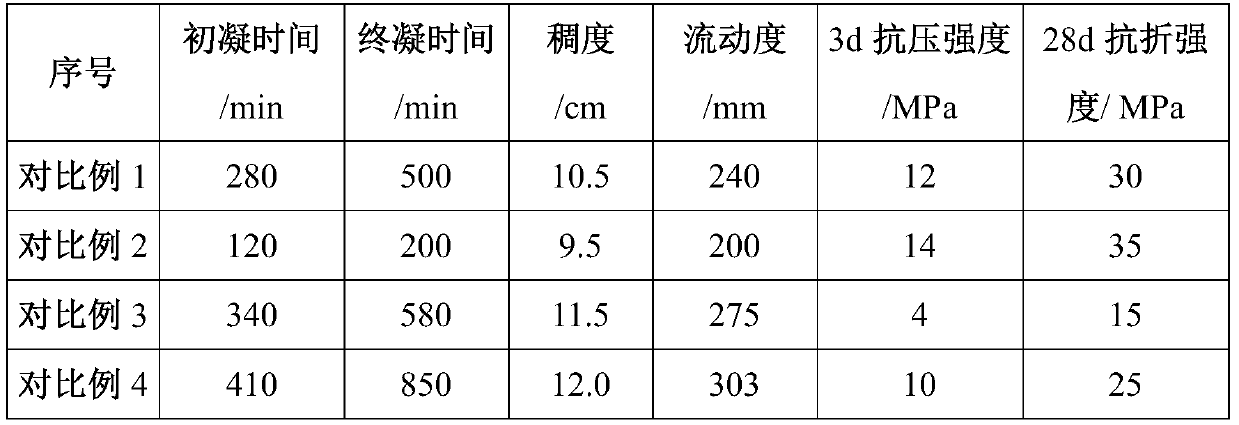

Industrial waste residue multi-component composite shield tunnel wall post-grouting material and preparation method thereof

The invention discloses an industrial waste residue multi-component composite shield tunnel wall post-grouting material and a preparation method thereof. The material comprises the following raw materials in parts by weight: 50 to 70 parts of fly ash, 10 to 30 parts of blast furnace slag micro-powder, 10 to 30 parts of inert steel slag micro-powder, 35 to 55 parts of an alkaline excitant, 150 to 200 parts of fine sand, 1 to 2 parts of a water reducing agent, 0 to 0.5 part of a retarder and 80 to 120 parts of water. The method comprises the following steps: adding sodium hydroxide into sodium water glass to prepare a modified sodium silicate solution; adding water into the modified sodium silicate solution to prepare an excitant solution, sealing the excitant solution with a polyethylene film, and cooling the excitant solution for later use; weighing fly ash, blast furnace slag micro-powder, inert steel slag micro-powder, fine sand, the water reducing agent and the retarder, and then putting the weighed materials into a stirrer to be uniformly stirred; and mixing the uniformly stirred powder with a pre-prepared excitant solution in proportion, and uniformly stirring. The method is simple in preparation process and low in cost, has the advantages of environmental protection, high efficiency and resource recycling, and has a wide application prospect.

Owner:SOUTHEAST UNIV

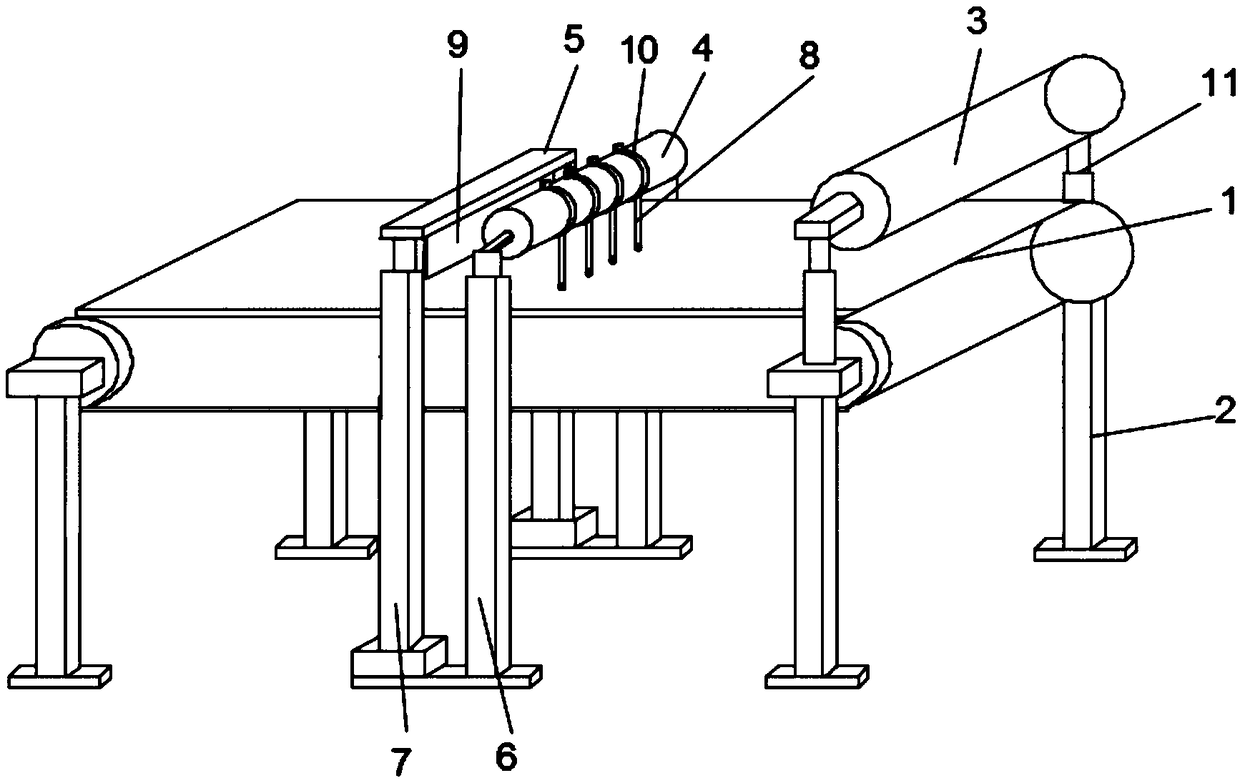

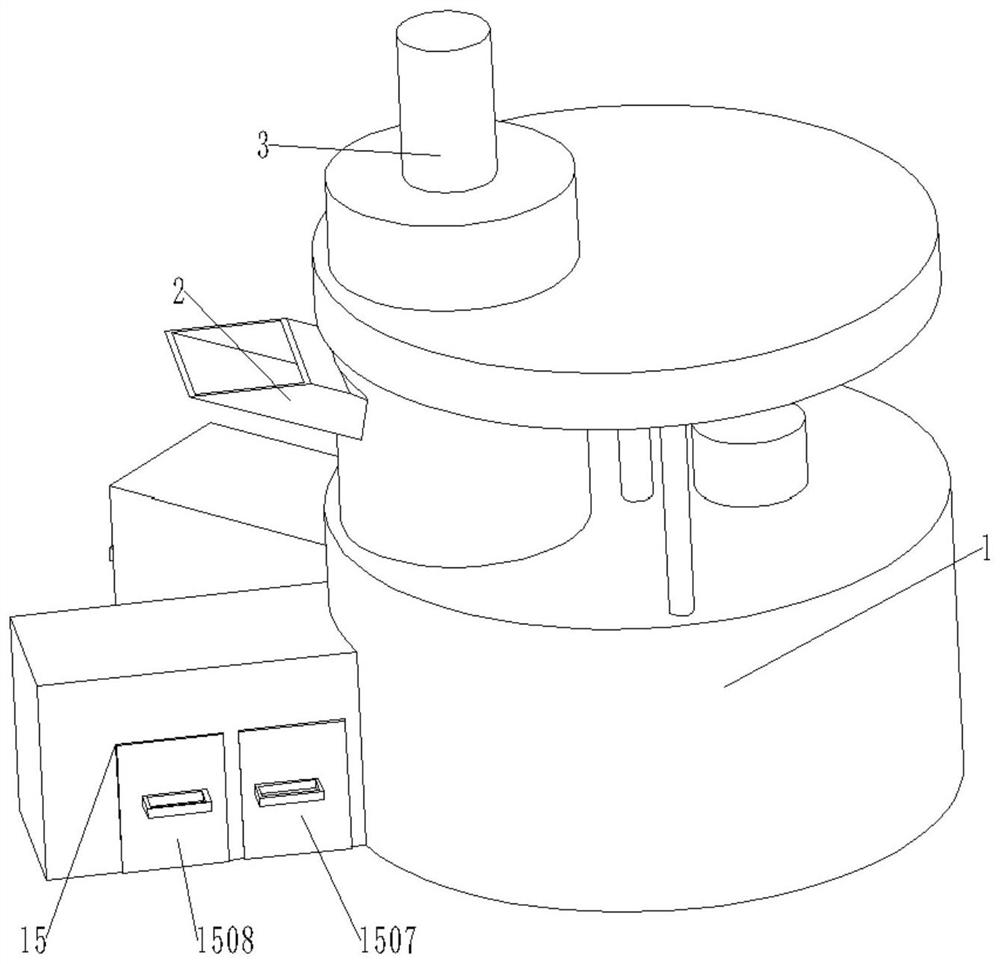

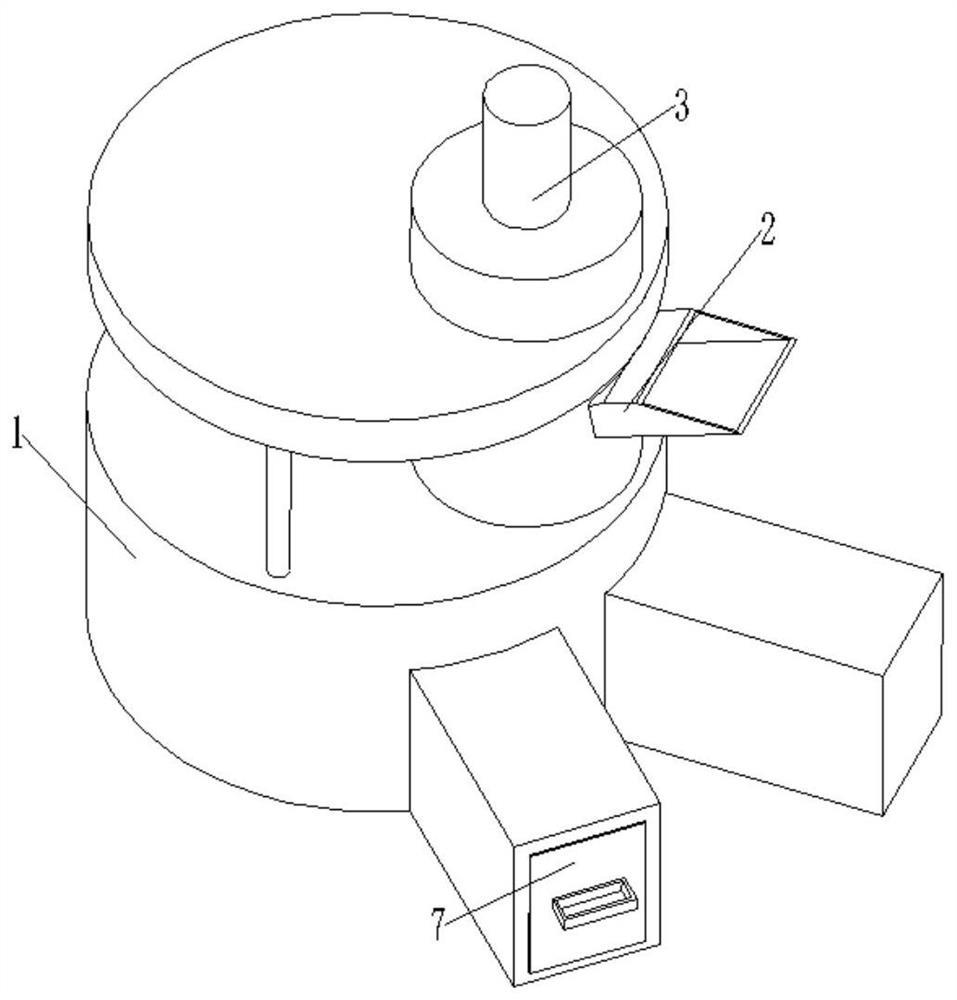

Sponge cutting machine

InactiveCN109500921AImprove cutting efficiencyExpand the scope of useMetal working apparatusMechanical engineeringSponge

The invention discloses a sponge cutting machine, and relates to the technical field of sponge cutting equipment. The sponge cutting machine comprises a conveyor belt, supporting columns are arrangedat the bottom of the conveyor belt, and a pressing mechanism, a first cutting mechanism and a second cutting mechanism are sequentially arranged above the conveyor belt from right to left, wherein thefirst cutting mechanism comprises a first mounting rod horizontally arranged, the second cutting mechanism comprises a second mounting rod horizontally arranged, the second mounting rod is mounted onthe ground through a lifting support, the length direction of the first mounting rod and the length direction of the second mounting rod are perpendicular to the movement direction of the conveyor belt, first cutters are arranged at the bottom of the first mounting rod at intervals, a second cutter is arranged at the bottom of the second mounting rod, and the width of the second cutter is largerthan the width of the conveyor belt. According to the sponge cutting machine, the variable-pitch lateral cutters are arranged so that the sponges with different widths can be cut out; the longitudinalcutter is arranged so that the sponges with different lengths can be cut out; and the sponges can be cut out according to different sizes, so that the sponge cutting machine has the wide applicationrange and high cutting efficiency.

Owner:四川雷恩新材料有限公司

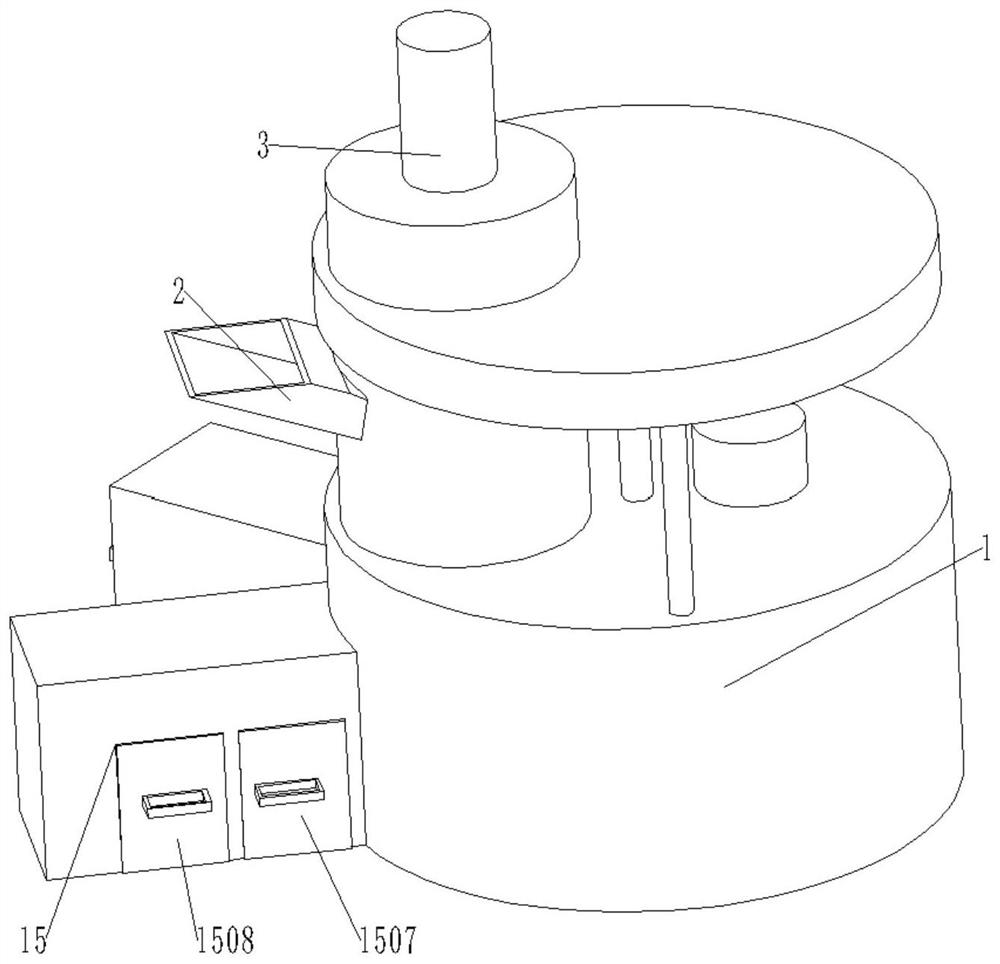

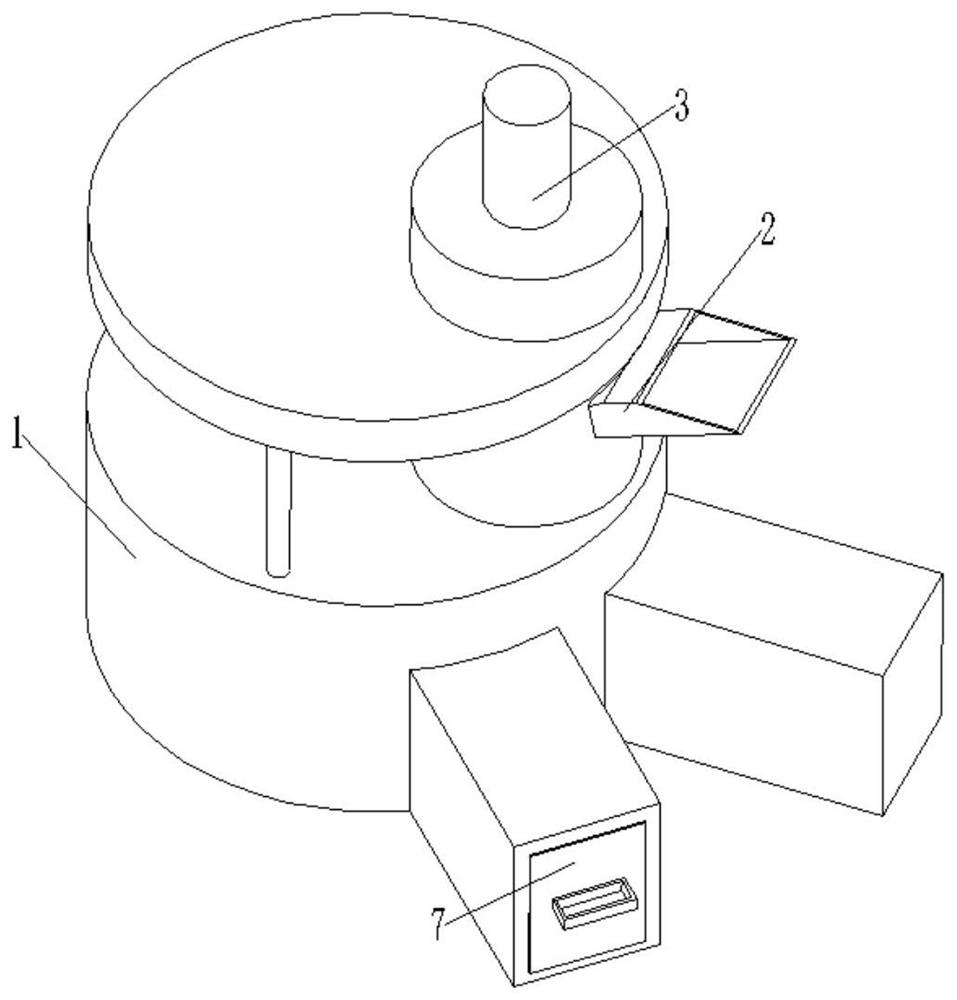

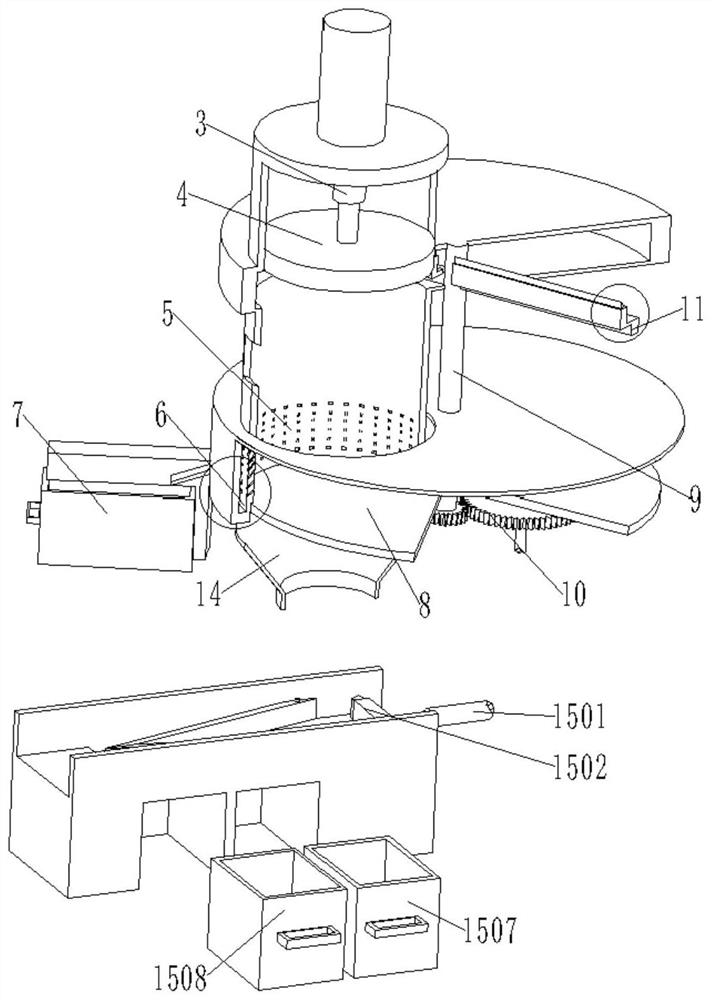

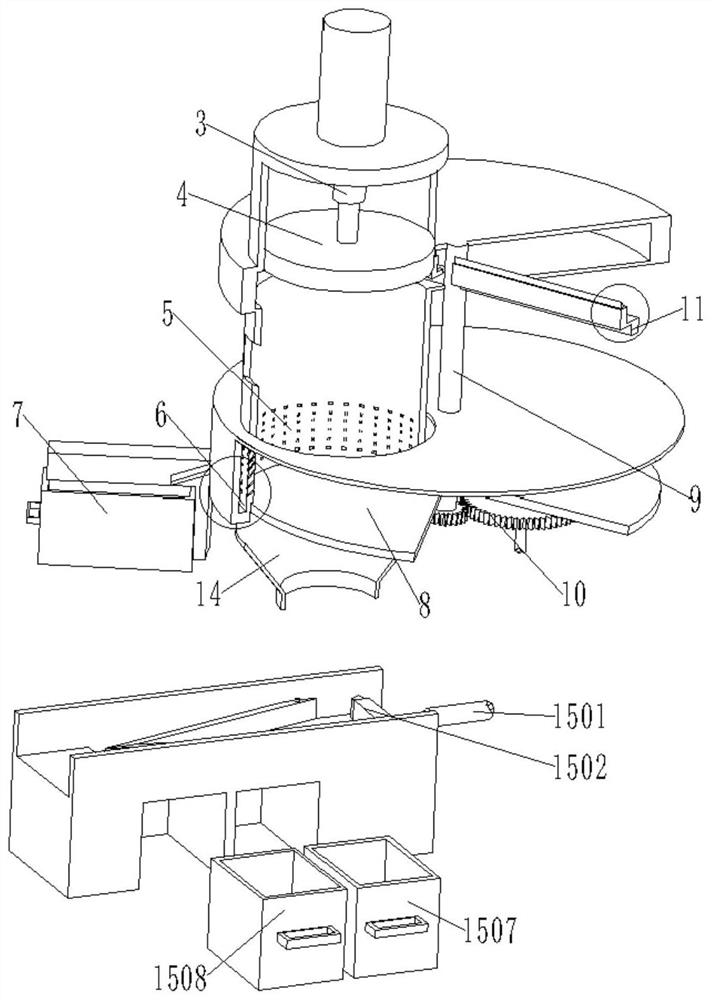

Environment-friendly composting treatment equipment for solid-liquid livestock breeding waste

ActiveCN111921247AEasy to separate and handleEasy to handleClimate change adaptationExcrement fertilisersLiquid wasteCrop livestock

The invention discloses environment-friendly composting treatment equipment for solid-liquid livestock breeding waste. According to the equipment in the invention, an extrusion disc, a drainage groove, an arc-shaped plate and a collection hopper are arranged, so solid-liquid mixed waste can be subjected to separation treatment; the solid-liquid waste is subjected to centralized extrusion through the extrusion disc; after the liquid is separated from the solid, the liquid enters a drainage groove from first filtering holes and is then collected in a first liquid waste collecting box in a centralized manner; an L-shaped cleaning scraping plate and a movable extrusion block are arranged, so waste adhered onto the bottom end face of the extrusion disc can be extruded in a centralized manner; and on the other hand, through the arrangement of an auxiliary solid-liquid separation treatment mechanism, solid-liquid waste can be well separated, separated solid waste and separated liquid waste can be well treated, no pollution is caused to the environment, and environmental protection and high efficiency are achieved.

Owner:SHANDONG ZHIFENG NONGHUA GRP

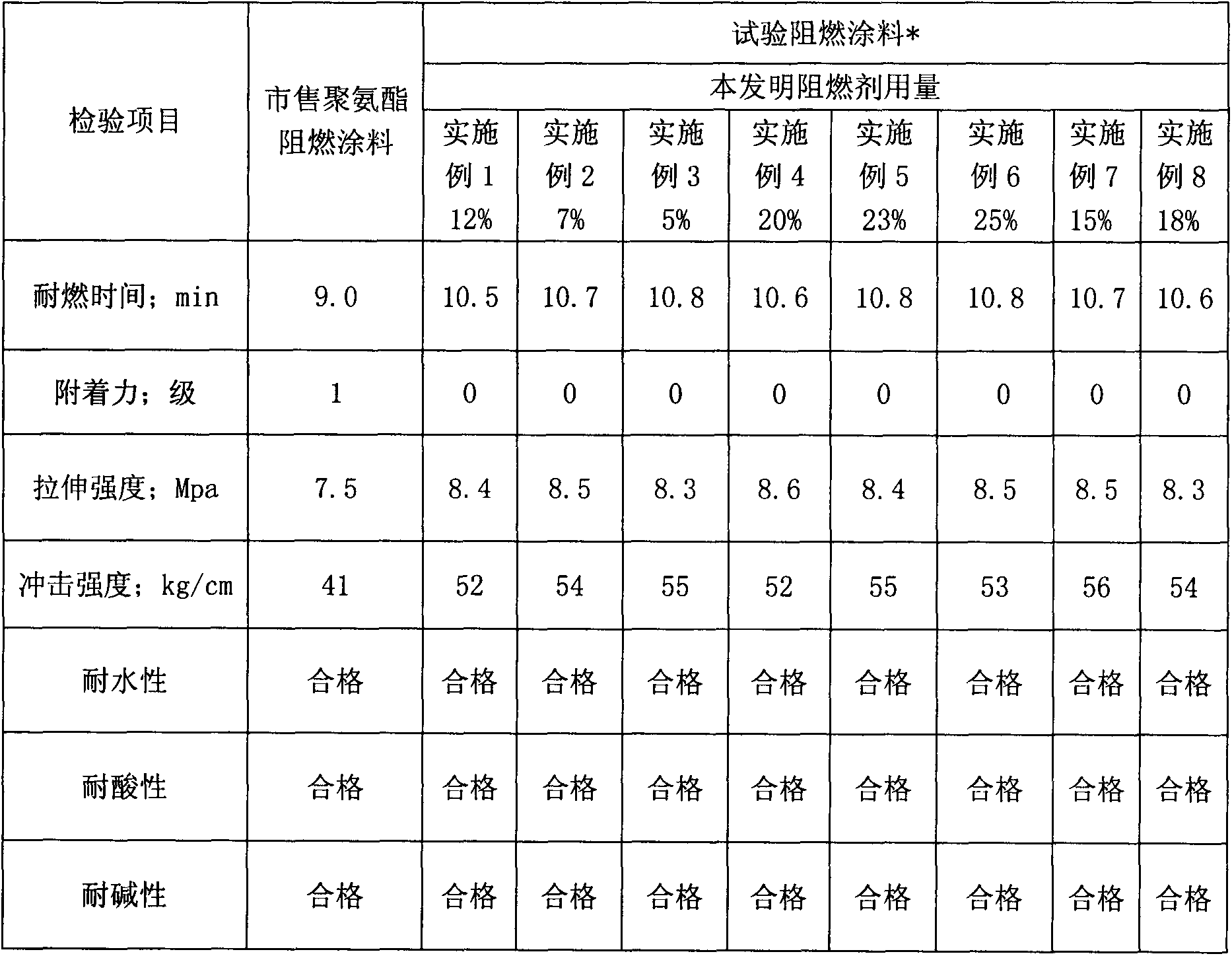

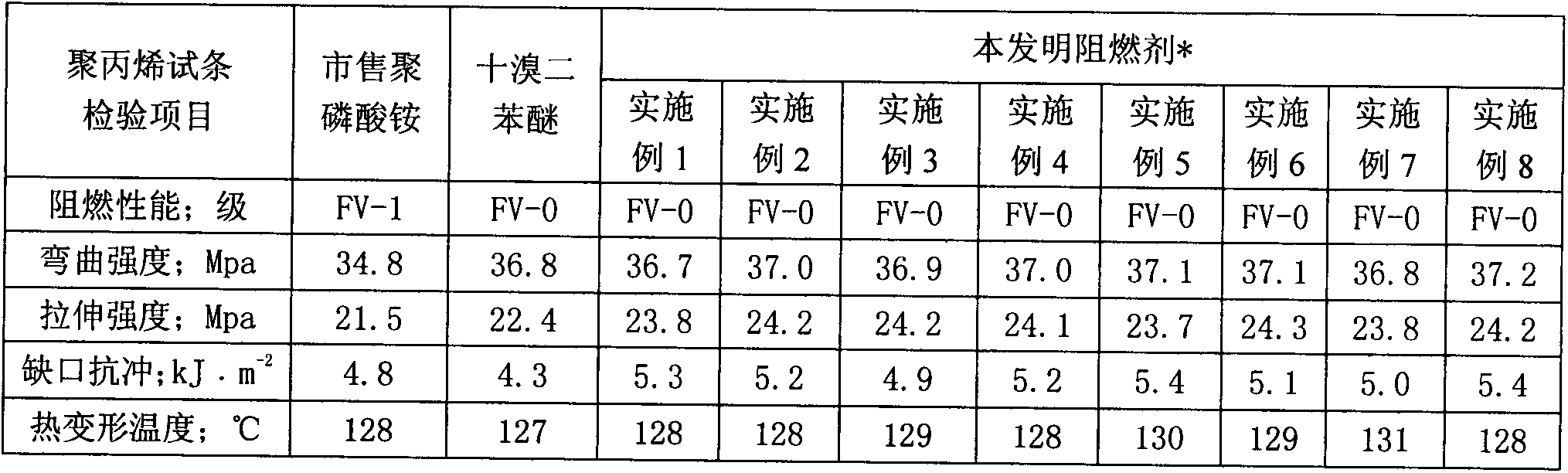

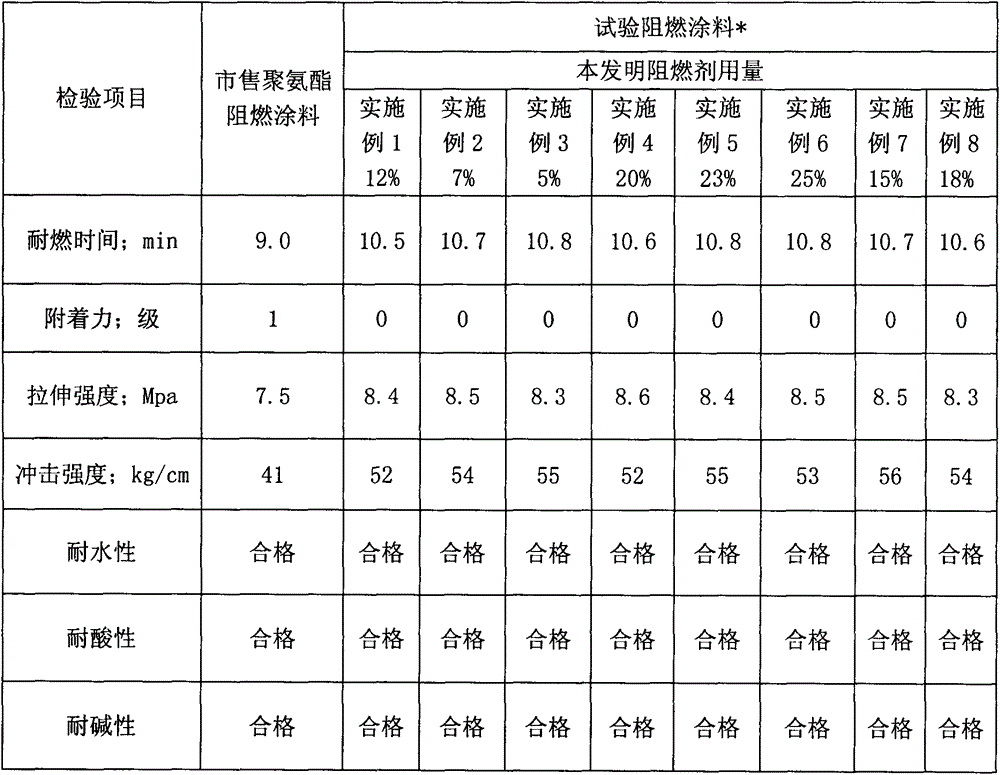

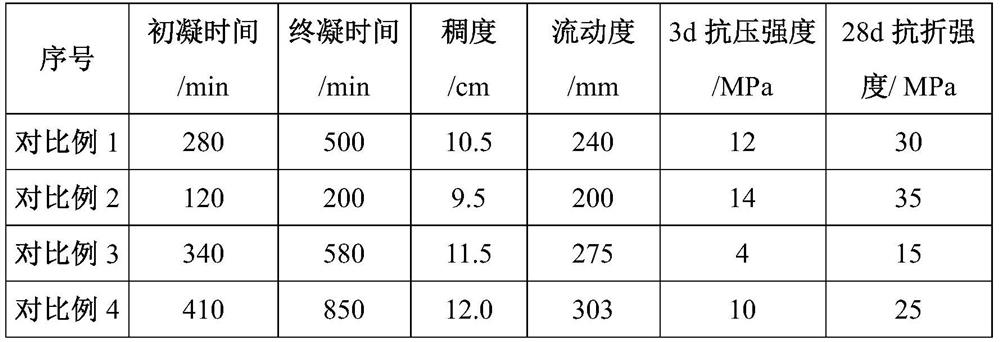

Preparation method for non-halogen fire retardant containing phosphorus and molybdenum

ActiveCN103289200AEnvironmentally friendly and efficientFireproof paintsPolyurea/polyurethane coatingsHalogenEngineering plastic

The invention provides a preparation of a non-halogen fire retardant containing phosphorus and molybdenum by polymeric aluminum phosphate, zinc molybdate and hydroxides which are used as main raw materials. The fire retardant comprises the following raw materials, in parts by weight: 50 to 90 of polymeric aluminum phosphate, 3 to 20 of zinc molybdate, 5 to 30 of hydroxides, 1 to 10 of silicon dioxide, and 0.1 to 0.5 of a coupling agent. The preparation method comprises: (1) after adding a certain amount of water into a reaction kettle, under a stirring condition, successively adding zinc molybdate, the hydroxides and silicon dioxide into the reaction kettle, and carrying out a reaction with stirring; (2) adding polymeric aluminum phosphate into the above materials, and fully stirring; and (3) after centrifugal dewatering, adding the coupling agent for processing during drying process, then crushing, weighing, packaging to obtain the product. The non-halogen fire retardant has the characteristics of environmental protection and high efficiency, and can be used in fire retardance of paints and engineering plastics.

Owner:GUANGXI XINJING TECH

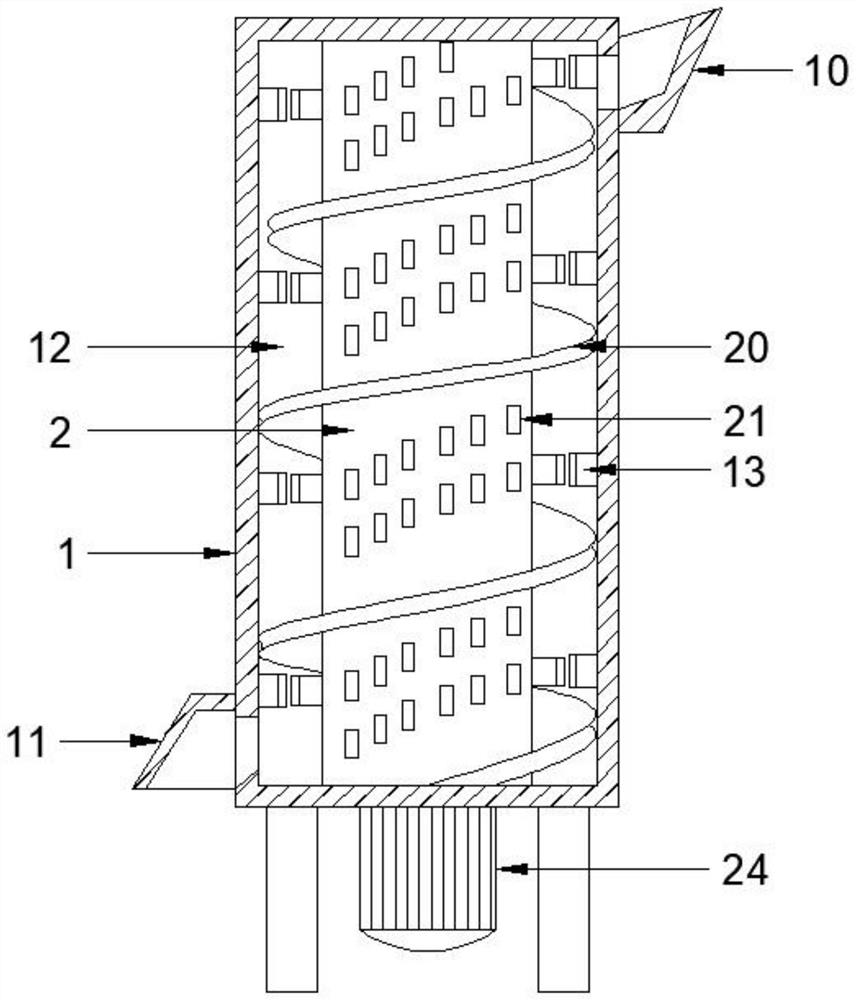

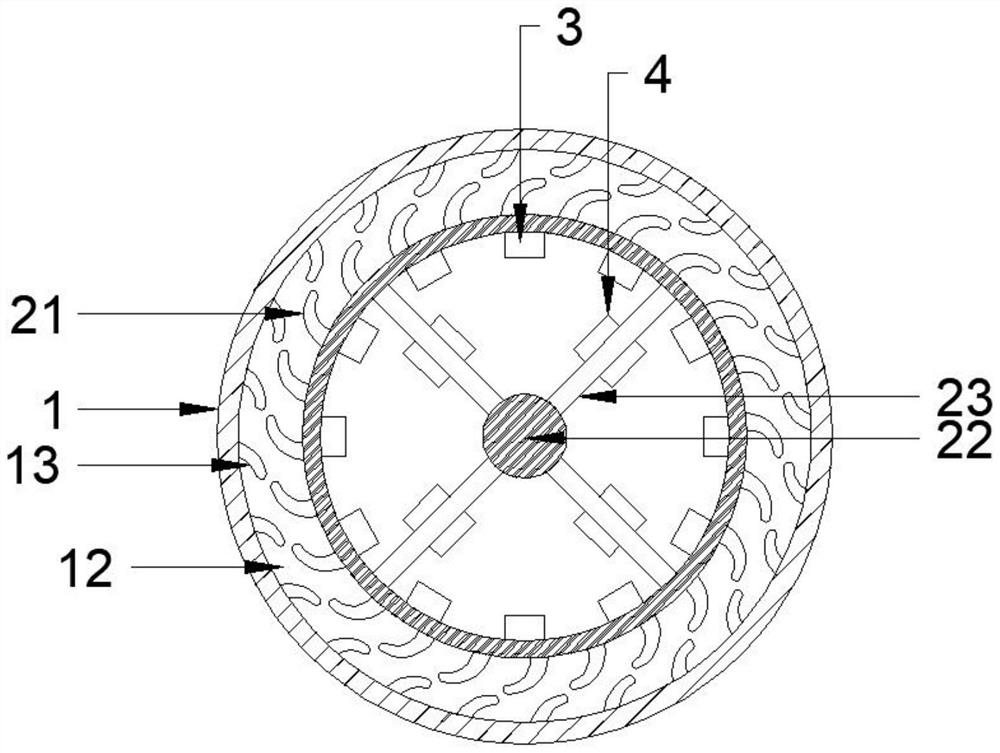

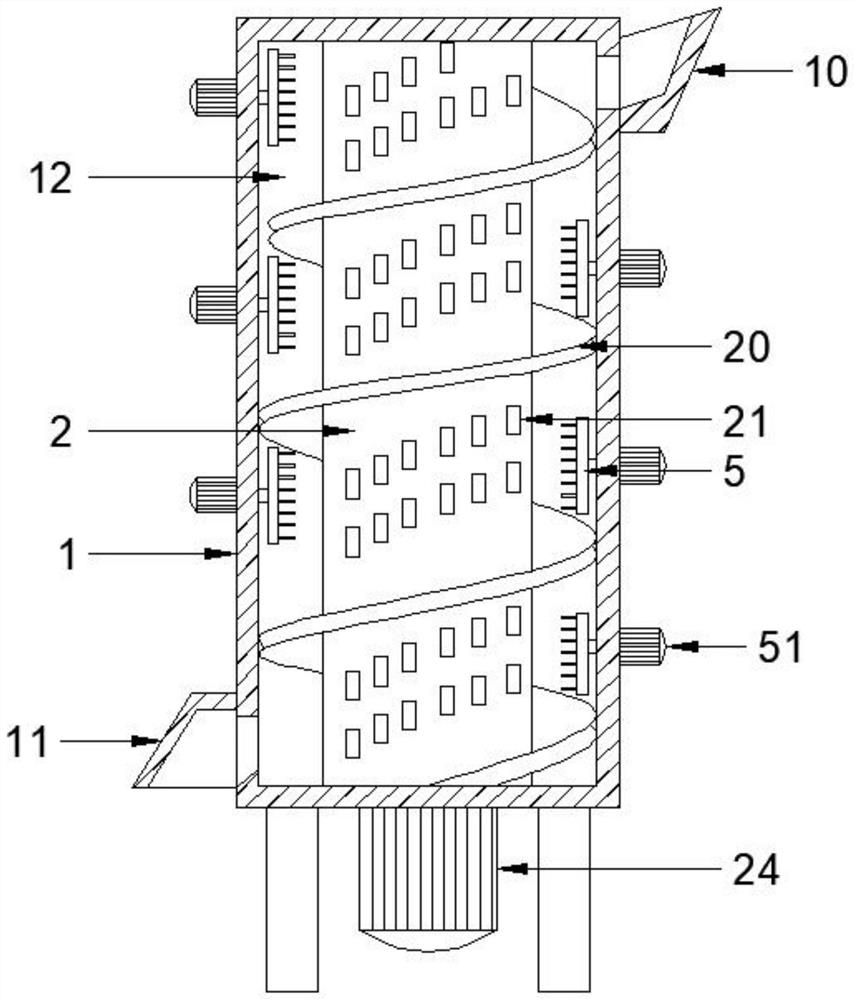

Impurity removal and purification device for feldspar ceramic raw materials

InactiveCN113600337AThe process of improving magnetic adsorptionGuaranteed passabilityMagnetic separationSpiral bladeElectromagnet

The invention discloses an impurity removal and purification device for feldspar ceramic raw materials. The impurity removal and purification device comprises an outer cylinder and an inner cylinder, the inner cylinder is rotationally arranged in the axis of the outer cylinder, a rotating mechanism is arranged at the outer end of the outer cylinder, a material cavity is formed in the area between the outer wall of the inner cylinder and the inner wall of the outer cylinder, and a feeding port and a discharging port which are communicated with the two ends of the material cavity are formed in the two ends of the side wall of the outer cylinder correspondingly; a material pushing spiral blade is spirally fixed on the outer wall of the inner cylinder, the outer edge of the material pushing spiral blade is in sliding connection with the inner wall of the outer cylinder and divides the material cavity into a spiral channel, a plurality of electromagnets used for adsorbing magnetic impurities in the material cavity are installed on the inner wall of the inner cylinder, and a material turning mechanism used for turning raw materials in the material cavity is arranged between the inner wall of the outer cylinder and the outer wall of the inner cylinder; and the magnetic adsorption process of the raw materials can be effectively improved through the spiral material pushing adsorption magnetic channel, magnetic impurities are removed while the passing ability of the raw materials is guaranteed, the raw materials are fully adsorbed through the material overturning mechanism, and the impurity removal process is rapid and environmentally friendly.

Owner:佛山市凯佳力机电设备有限公司

In-situ remediation method of heavy metal contaminated soil

ActiveCN110076192ASmall particle sizeLarge specific surface areaContaminated soil reclamationIonContaminated soils

The invention discloses an in-situ remediation method of heavy metal contaminated soil. The method comprises the steps as follows: preparing a spinning solution from chitosan and ion salt, performingelectrostatic spinning to obtain chitosan / zero-valent nano-iron composite fiber, twisting the composite fiber with glass fiber by a twisting machine to prepare a composite adsorption rope with heavy metal adsorption reduction capacity and certain strength, preparing a net, burying the net in the heavy metal contaminated soil, taking out the net after a period to finish in-situ adsorption and removal of heavy metals in soil. The method realizes in-situ remediation of the heavy metal contaminated soil, is environmentally friendly, efficient and convenient to operate, and overcomes the defect that traditional adsorption materials are difficult to separate from soil.

Owner:SOUTH CHINA UNIV OF TECH

Nano impressing method

InactiveCN103513511ALow manufacturing costSimplify operation stepsPhotomechanical apparatusPopulationNanometre

The invention discloses a nano impressing method which comprises the following steps of: (1) dropping a monomer solution on a liner to be impressed; (2) pressing a template on the liner, and dispersing the monomer solution and filling into a cavity in the template; (3) putting the template obtained in the step (2) into a nano impressing machine, after the liner is optically aligned with the template, penetrating ultraviolet light through a template radiation impressing area, solidifying and forming, and subsequently removing the template; and (4) etching a residual layer and transferring the pattern. The nano impressing method disclosed by the invention is simple in operation steps, convenient and flexible to use and beneficial for population and application, and has the advantages of environmental protection, high efficiency and the like.

Owner:WUXI IMPRINT NANO TECH

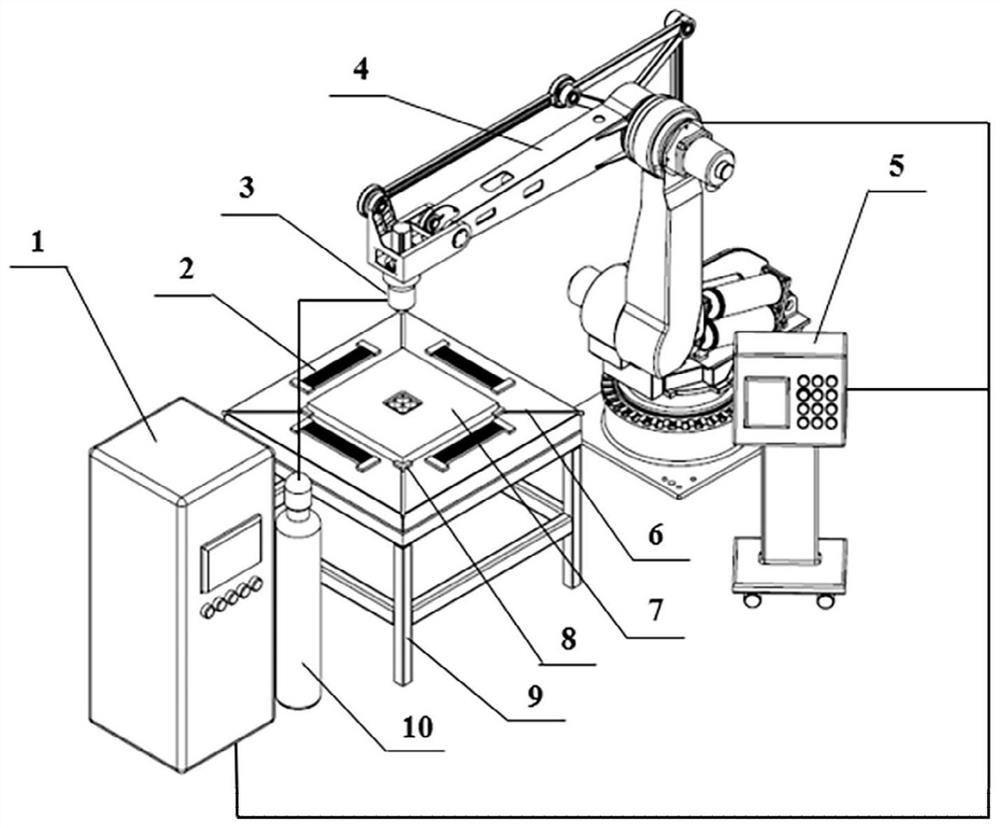

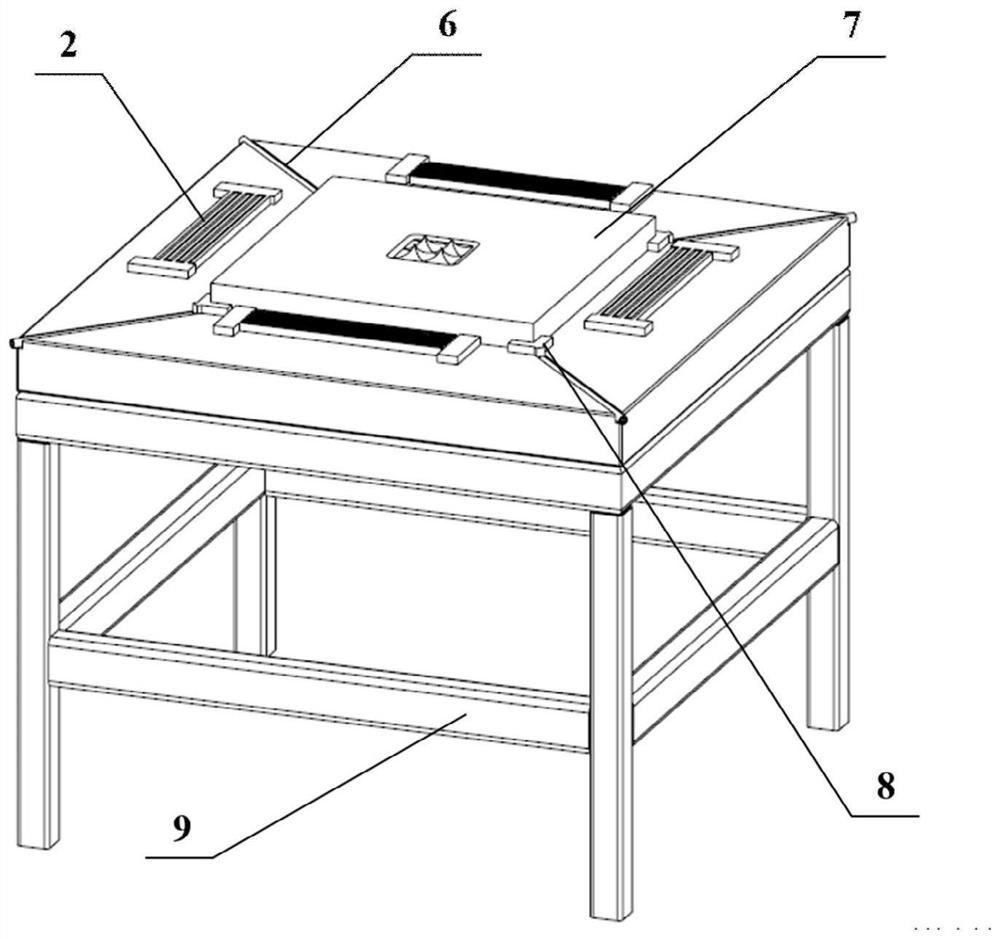

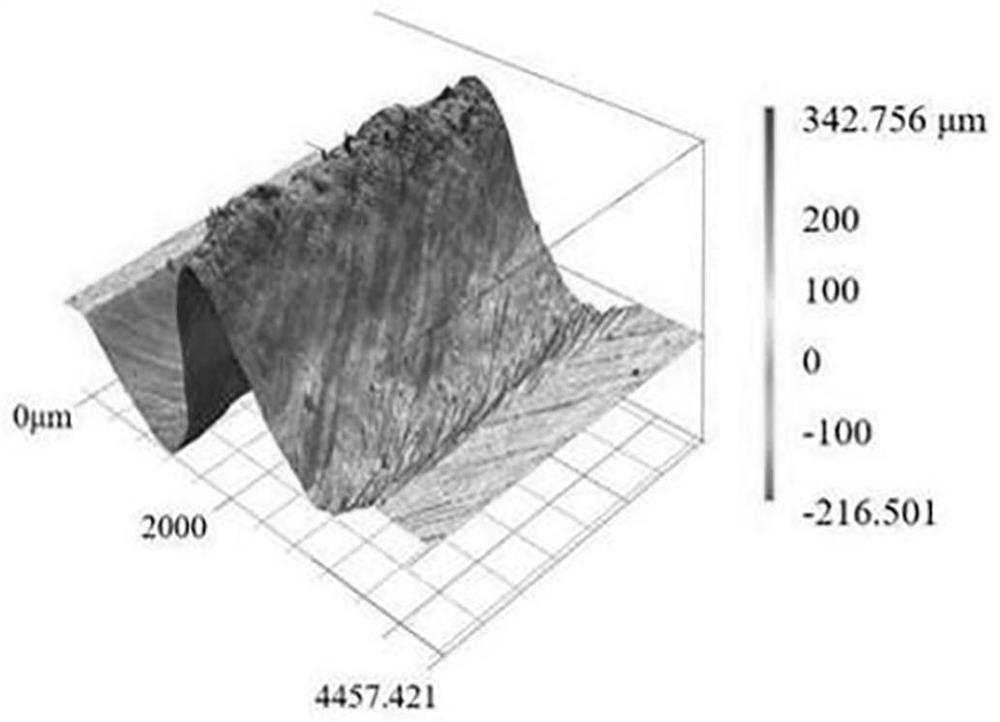

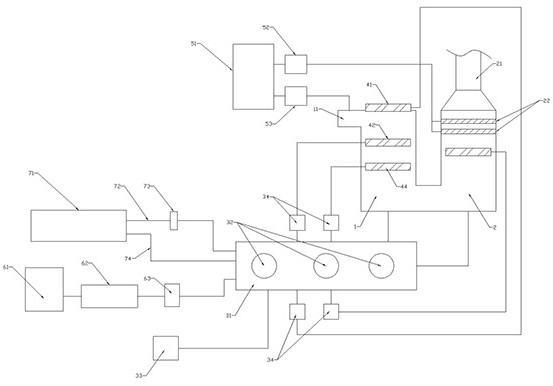

Device and method for preparing metal surface microarray through ultrasonic energy field assisted laser rapid melting

The invention discloses a device and method for preparing a metal surface microarray through ultrasonic energy field assisted laser rapid melting. The device mainly comprises laser forming equipment and a surface acoustic wave workbench. According to the device, a sound field is applied to a heated melt in the laser melting process, the amplitude, frequency and phase of an ultrasonic surface wave are changed by adjusting an ultrasonic signal generator and a power generator, and after a needed stable microarray structure is generated, a laser heat source is removed, and the melt is naturally cooled, solidified and formed; the surface microarray structure is rapidly formed and prepared in the laser melting process through the surface acoustic waves, the manufacturing process is simple, operation is convenient, and the production efficiency is high.

Owner:ZHEJIANG UNIV OF TECH

Flue gas desulfurization and discharge device

PendingCN112691536AImprove desulfurization effectLow costGas treatmentDispersed particle separationSlagProcess engineering

The invention discloses and provides a flue gas desulfurization and discharge device suitable for single-alkali desulfurization, and the device is reasonable in structure, convenient to operate and high in desulfurization and discharge efficiency and improves the cyclic utilization rate. The device comprises a water supply mechanism, a chemical supply mechanism, a circulating mechanism, a spraying mechanism, a slag discharging mechanism and a tower set, the water supply mechanism and the circulating mechanism are connected with the tower set respectively, the spraying mechanism is arranged in the tower set, and the chemical supply mechanism and the slag discharging mechanism are connected with the circulating mechanism respectively. The device is suitable for the field of ceramic tile processing production.

Owner:湖南旭日陶瓷有限公司

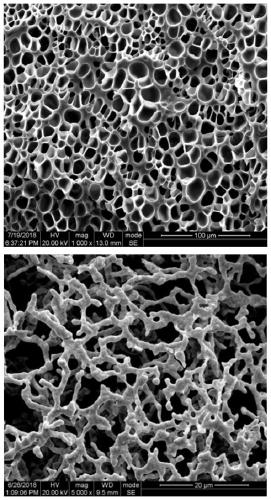

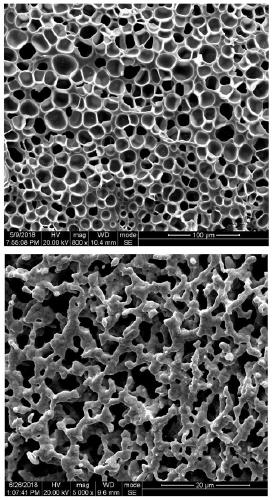

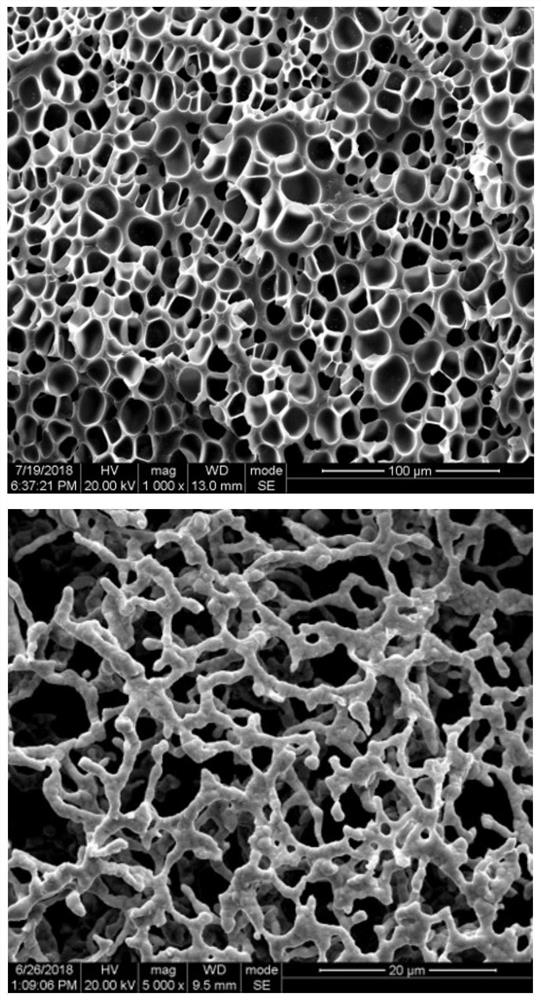

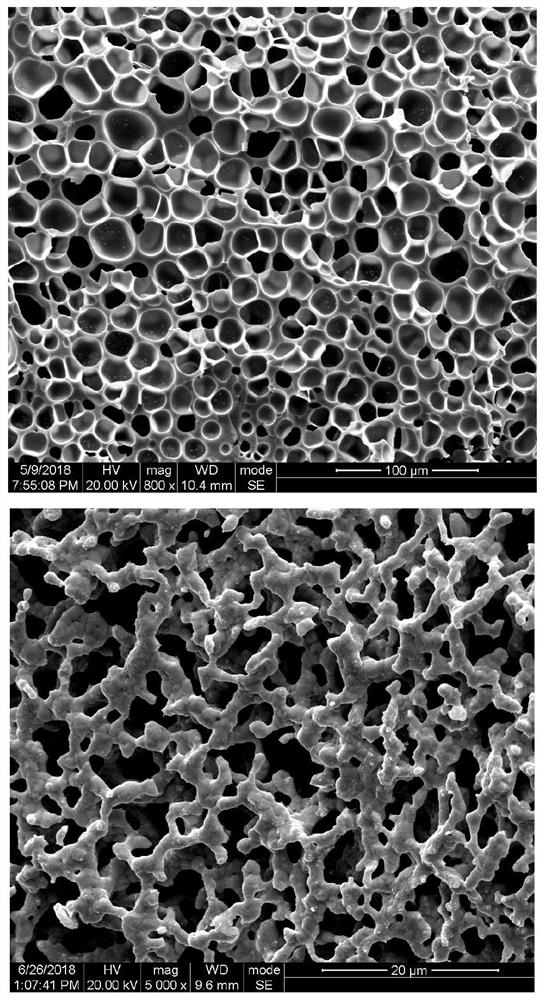

Method for preparing foamed silver catalyst based on supercritical carbon dioxide foaming technology

ActiveCN111111651AIncreased catalytic efficiency constantImprove catalytic stabilityOrganic compound preparationCatalyst activation/preparationPtru catalystPolyvinyl alcohol

The invention provides a method for preparing a foamed silver catalyst based on a supercritical carbon dioxide foaming technology. The method comprises the following steps: plasticizing and modifyingpolyvinyl alcohol, preparing a PVA / AgNO3 composite plate by adopting a mould pressing method, preparing a PVA / AgNO3 composite foam material by adopting a supercritical carbon dioxide kettle pressure foaming method, and performing in-situ solid-state reaction on the obtained composite foam material, thereby obtaining the foamed silver catalyst. According to the invention, process conditions are optimized and combined; the foam pore structure is optimized, so that the foamed silver catalyst with characteristics of good catalytic efficiency and certain mechanical strength is obtained after the in-situ solid phase reaction, the foam pore size distribution of the foamed silver catalyst prepared through the method is uniform, the product is pure, and the catalytic performance is significantly superior to that of the similar products on the market.

Owner:SICHUAN UNIV

An environment-friendly animal husbandry solid-liquid waste composting treatment equipment

ActiveCN111921247BEasy to separate and handleEasy to handleClimate change adaptationExcrement fertilisersLiquid wasteCrop livestock

The invention discloses an environment-friendly animal husbandry solid-liquid waste composting treatment equipment. The extrusion disk, drainage groove, arc-shaped plate and collecting hopper provided in the invention can separate and process solid-liquid mixed waste. The extrusion disc squeezes the solid and liquid waste in a concentrated manner. After the liquid and solid are separated, they will enter the drainage groove from the first filter hole, and then be collected in the first liquid waste collection box, and pass through the set L-shaped The cleaning scraper and the movable extrusion block can also clean up the waste adhered to the bottom surface of the extrusion disc. On the other hand, the solid-liquid separation treatment auxiliary mechanism can be used to separate the solid-liquid waste well. Treatment, and the separated solid waste and liquid waste can be well treated, will not pollute the environment, and is environmentally friendly and efficient.

Owner:SHANDONG ZHIFENG NONGHUA GRP

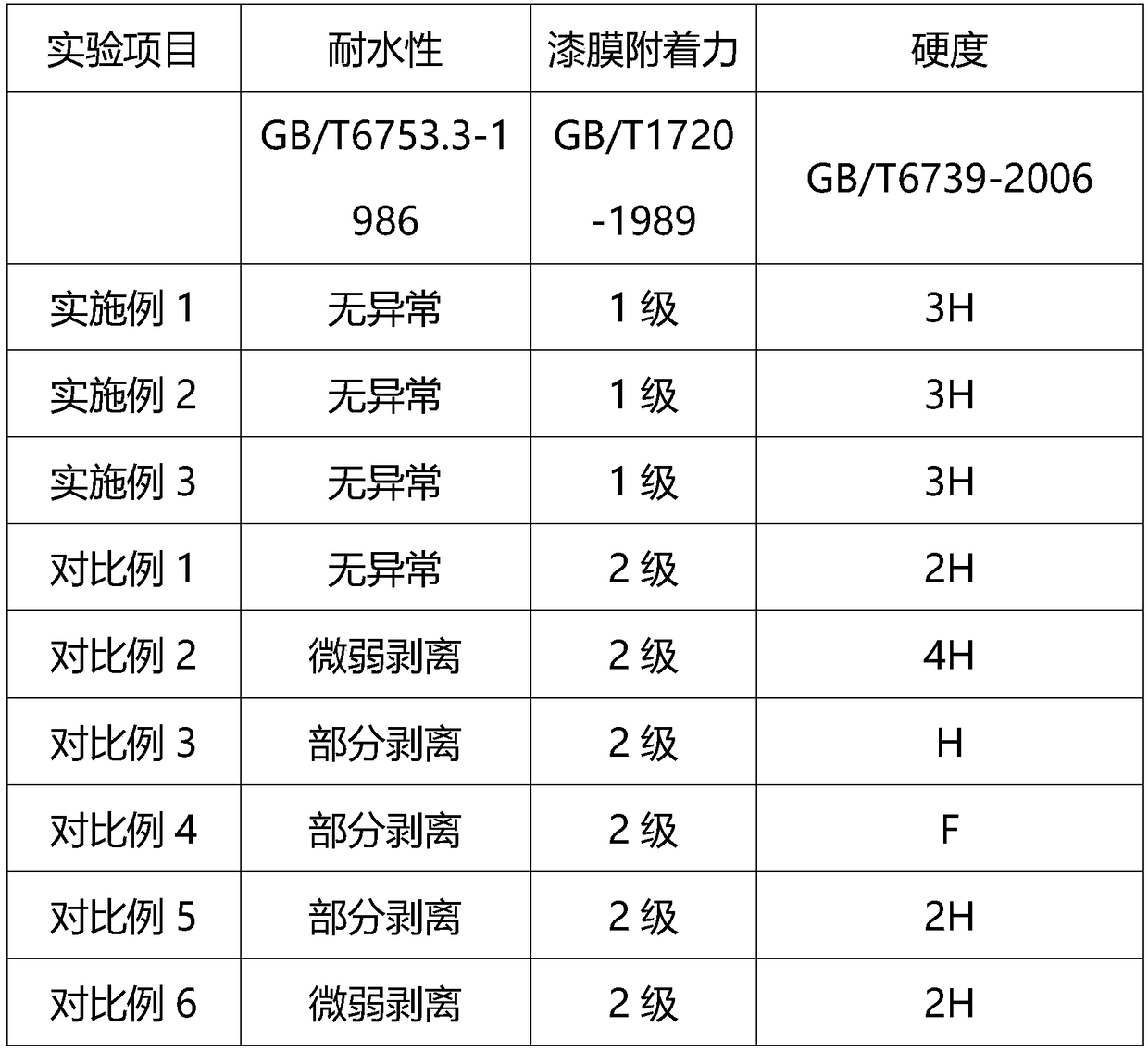

Water-based ecological environment-friendly paint for pencil wooden holders and preparation method thereof

The invention discloses water-based ecological environment-friendly paint for pencil wooden holders and a preparation method thereof. The water-based ecological environment-friendly paint is preparedfrom water-based color paste, water-based acrylate resin emulsion, compound ionic liquid, stabilizer, dispersant, a flatting agent, a defoaming agent, a thickening agent and alcohol, wherein the water-based color paste is prepared from titanium dioxide, tricalcium phosphate, corn oligopeptides powder and deionized water; and the compound ionic liquid is prepared from chlorinated 1-en-butyl-3-methylimidazole and 1-ethyl-3-methylimidazoliumacetate in a mixing ratio of (4-6):(2-4). The water-based ecological environment-friendly paint for pencil wooden holders has the advantages of high environment-friendly safety, strong adhesive force and better water resistance.

Owner:浙江安益新材料有限公司

Aluminium zinc phosphomolybdate compounded rustproof pigment and production method thereof

ActiveCN101864214BNon-toxicEnvironmentally friendly and efficientAnti-corrosive paintsPhosphorus compoundsPhosphomolybdic acidPhosphoric acid

The invention provides an aluminium zinc phosphomolybdate compounded rustproof pigment which takes aluminium zinc phosphate, zinc molybdate, aluminium phosphate and the like as main raw materials to synthesise aluminium zinc phosphomolybdate compounded rustproof pigment. The rustproof pigment is prepared from the following raw materials in parts by weight: 50-75 parts of aluminium zinc phosphomolybdate, 10-20 parts of aluminium phosphate, 3-10 parts of zinc oxide, 1-8 parts of barium sulphate, 0.5-5 parts of zinc molybdate and 0.1-0.5 part of accessory ingredient. The preparation method comprises the following steps: (1) after a certain quantity of water is added into an agitated reactor, successively adding the aluminium zinc phosphate, aluminium phosphate and zinc molybdate into an agitated reactor under the condition of stirring, stirring at the temperature of 50-100 DEG C; (2) fully stirring the materials with barium sulfate and zinc oxide, and carrying out modified treatment; (3)cooling the materials to be below 50 DEG C, and adding the accessory ingredient to carry out surface treatment; and (4) carrying out centrifugal dehydration, drying, smashing, weighting and packaginginto products. The invention has the characteristics of no toxin, environment protection and high efficiency of the rustproof pigment and can completely replace the traditional toxic heavy metal rustproof pigment, such as red lead, zinc chrome and the like in the industrial pigment.

Owner:GUANGXI XINJING TECH

Organic fertilizer and preparation method thereof

InactiveCN109734495AEasy to produce and useIncrease crop yieldsBio-organic fraction processingOrganic fertiliser preparationChemistryCrop

The invention belongs to the field of organic fertilizers, and particularly discloses an organic fertilizer and a preparation method thereof. The organic fertilizer comprises the following raw materials in parts by weight: 20-50 parts of animal feces, 10-30 parts of vegetable residue, 20-40 parts of fruit residue, 2-4 parts of trace elements, 3-7 parts of biological bacteria and 10-60 parts of water. The method for producing and using the organic fertilizer is convenient, safe and effective. It is proved that the organic fertilizer has the characteristics of improving the yield of crops, reducing the usage amount of chemical fertilizers, pesticides and the like. The organic fertilizer is prepared by composting and fermentation under the action of biological bacteria, long-term use can solve the problems of soil hardening and hardening caused by the use of chemical fertilizers and pesticides in the production period, and the quality of crops can be effectively improved.

Owner:自贡佳禾新能源科技有限公司

Method for preparing foam silver catalyst based on supercritical carbon dioxide foaming technology

ActiveCN111111651BHigh catalytic efficiencyHave mechanical strengthOrganic compound preparationCatalyst activation/preparationPtru catalystPolyvinyl alcohol

The invention provides a method for preparing a foam silver catalyst based on supercritical carbon dioxide foaming technology. The method first plasticizes and modifies polyvinyl alcohol and then uses a molding method to prepare PVA / AgNO. 3 Composite sheet, and then prepare PVA / AgNO through supercritical carbon dioxide autoclave foaming method 3 Composite foam material, the obtained composite foam material is subjected to in-situ solid-state reaction to obtain a foam silver catalyst. The present invention optimizes the cell structure by optimizing the combination of process conditions, thereby obtaining a silver foam catalyst with better catalytic efficiency and a certain mechanical strength after in-situ solid phase reaction. The foam silver catalyst prepared by this method has The foam pore size is evenly distributed, the product is pure, and the catalytic performance is significantly better than similar products on the market.

Owner:SICHUAN UNIV

A kind of small-radius bending and curling method of magnesium alloy plate

ActiveCN110129696BRigid enoughStrong enoughShaping toolsMetal rolling arrangementsThermal treatmentMagnesium alloy

The invention discloses a small-radius bending and curling method of a magnesium alloy plate, which comprises the following steps: performing hot rough rolling, hot intermediate rolling and hot finish rolling on the magnesium alloy sequentially under corresponding temperature conditions; water cooling the thin plate to room temperature after heat treatment; Heating treatment at the edge of the curling; put it into a cold mold for forming and quenching, and complete the bending and curling of the magnesium alloy sheet. The present invention can adopt multiple heating methods to heat the curling part, and then combine the hot stamping forming process to carry out curling and bending, which can obviously improve the curling problem of the magnesium alloy plate, and has good surface quality and mechanical properties.

Owner:SOUTHWEST JIAOTONG UNIV

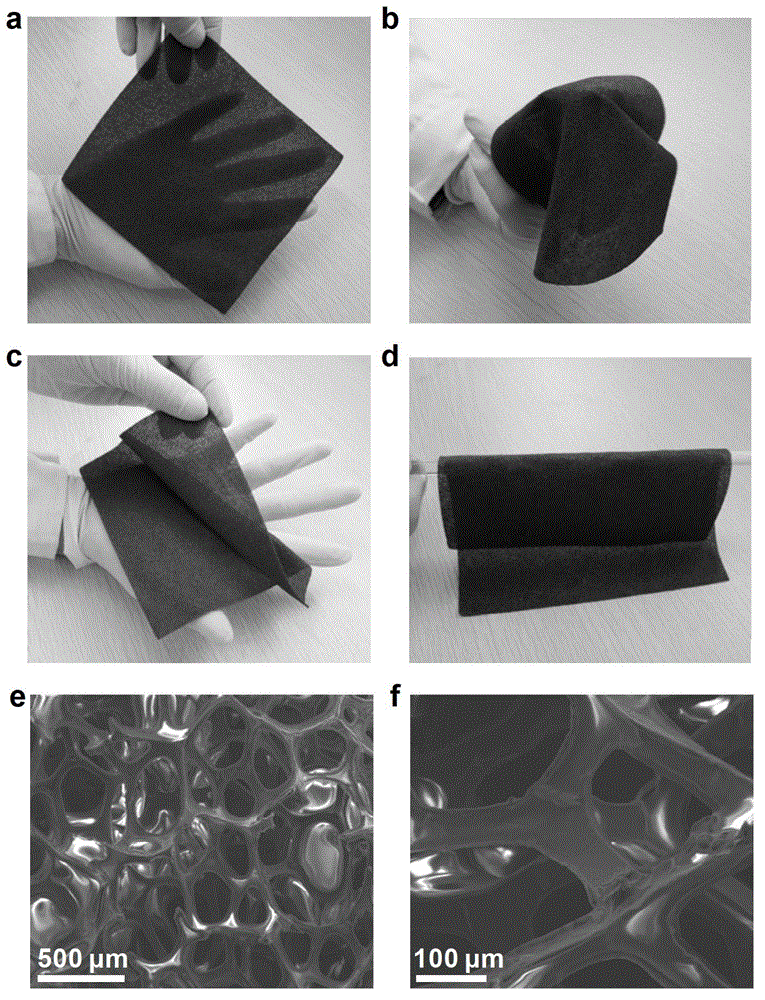

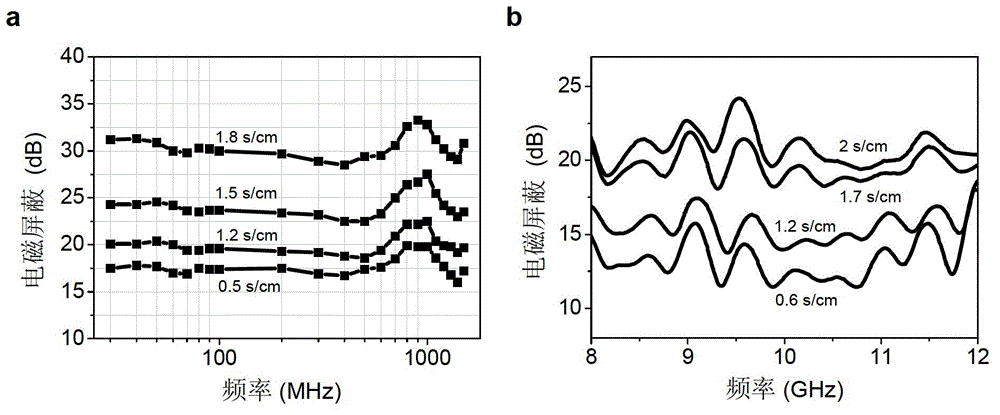

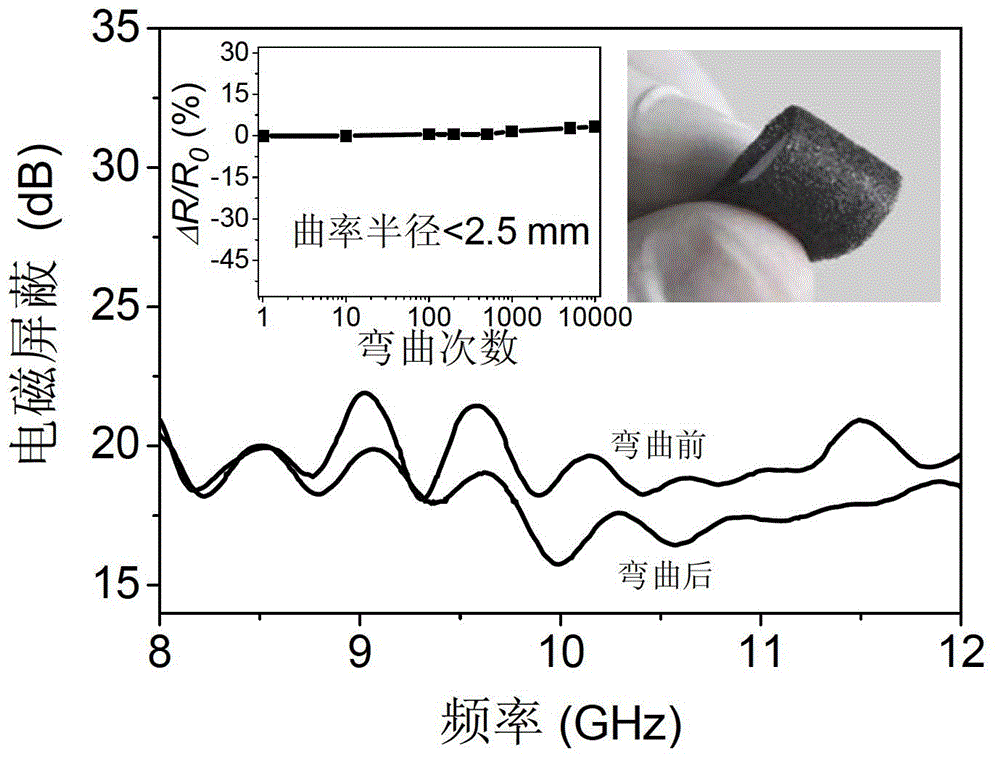

Light flexible graphene/polymer foam electromagnetic shielding material, preparation method and application thereof

ActiveCN103030974BEasy to manufacturePreserve intrinsic propertiesElectromagnetic shieldingCvd graphene

The invention relates to the field of graphene-based foam composites, in particular to a light flexible graphene / polymer foam electromagnetic shielding material, and a preparation method and an application thereof. The preparation method comprises the steps that three-dimensional full-communicated metal foam grown with graphene and a high molecular polymer precursor are adopted; a graphene / metal foam complex is mixed with the high molecular polymer precursor to ensure that the surface of the graphene / metal foam complex is coated with a layer of high molecular polymer precursor; the high molecular polymer precursor in a mixture is cured and then dissolved to remove a porous metal base; and then the light flexible graphene / polymer foam electromagnetic shielding material is obtained. The graphene / polymer foam composite has very low density and good flexibility, and graphene in the graphene / polymer foam composite forms a full-communicated network in a seamless connection manner, so that the composite has excellent conductivity and electromagnetic shielding property, and can be widely applied to the fields of aerospaces, portable electronic devices and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Electronic equipment for using environment-protection lamp to trap and kill mosquitoes and other insects

InactiveCN107148960AEnvironmentally friendly and efficientInsect catchers and killersSide effectTrapping

The invention discloses an electronic device for trapping and killing mosquitoes with an environmental lamp, relates to the technical field of daily necessities, and is specifically a mosquito killing device. At present, many chemicals are used to kill mosquitoes, which cannot be reused, and the side effects are not small. This invention aims to provide a reusable, safe and low-side-effect mosquito killing device. To achieve this goal, the technical solution of this invention includes the following technical content; an electronic device for trapping and killing mosquitoes with environmental protection lamps, which is characterized by: : photocatalytic net and mosquito trapping mosquito box, wind vortex suction box; also includes a dead mosquito collection box; lifting plate is a sphere assembled from multiple plates; also includes a number of circuits and electronic equipment equipped with each other ; The bottom surface of the body also includes: a photocatalytic net and a mosquito trap lamp. In summary, this invention has beneficial effects of environmental protection and high efficiency.

Owner:刘凤娇

Driving system for mining hybrid power trackless rubber-tyred vehicle

ActiveCN103009991BEnvironmentally friendly and efficientPower footGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectricityCoupling

The invention discloses a driving system for a mining hybrid power trackless rubber-tyred vehicle, belonging to the technical field of driving devices. The driving system comprises an engine, a generator, a storage battery, an illumination signal lamp, an electric horn, a display screen, an operation box, a pedal switch, a control device and a motor, wherein the engine is electrically connected with the generator, the illumination signal lamp and the electric horn are electrically connected with the storage battery, the generator, the operation box, the pedal switch, the display screen, the storage battery and the motor are all electrically connected with the control device. The driving system is characterized by further comprising a coupling device, wherein the generator, the control device and the motor are electrically connected with the coupling device, and the coupling device is electrically connected with the driving axle of the trackless rubber-tyred vehicle. The driving system has the beneficial effects that as the driving system for the hybrid power trackless rubber-tyred vehicle is jointly driven by the engine and the storage battery, the driving system has the advantages of the sufficient power and the strong endurance capability of a diesel engine as well as the environment protection, high efficiency and the flexibility of the storage battery, and multiple operational modes of the driving system are suitable for complex road situations under a shaft.

Owner:CHINA UNIV OF MINING & TECH

A kind of preparation method of non-halogen flame retardant containing phosphorus and molybdenum

ActiveCN103289200BEnvironmentally friendly and efficientFireproof paintsPolyurea/polyurethane coatingsHalogenEngineering plastic

Owner:GUANGXI XINJING TECH

A kind of post-grouting material of industrial waste multi-component composite shield tunnel wall and its preparation method

The invention discloses an industrial waste slag multi-component composite shield tunnel wall grouting material and a preparation method thereof. The material contains the following raw materials in parts by weight: 50-70 parts of fly ash, 10-30 parts of blast furnace slag fine powder , 10-30 parts of inert steel slag powder, 35-55 parts of alkaline activator, 150-200 parts of fine sand, 1-2 parts of water reducing agent, 0-0.5 parts of retarder, 80-120 parts of water. The method comprises the following steps: adding sodium hydroxide into sodium water glass to configure a modified sodium silicate solution; adding water to the modified sodium silicate solution to configure an activator solution, sealing it with a polyethylene film, and cooling and set aside; weigh fly ash, blast furnace slag fine powder, inert steel slag fine powder, fine sand, water reducer, retarder, and then put them into a mixer and stir evenly; The activator solution was mixed in proportion and stirred evenly. The preparation method of the invention is simple, low in cost, has the advantages of environmental protection, high efficiency and resource recycling, and has broad application prospects.

Owner:SOUTHEAST UNIV

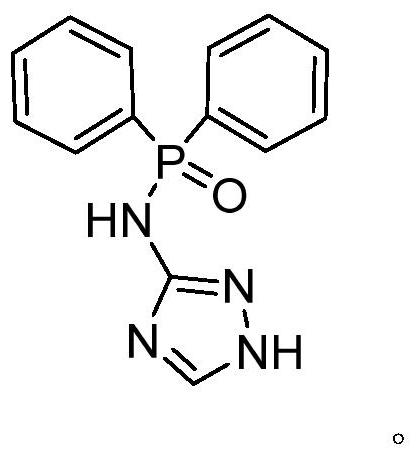

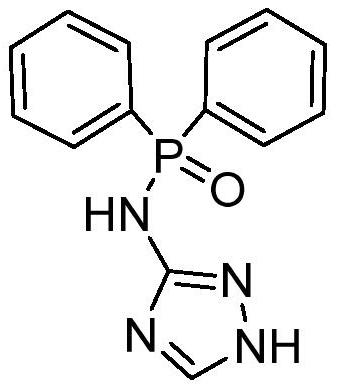

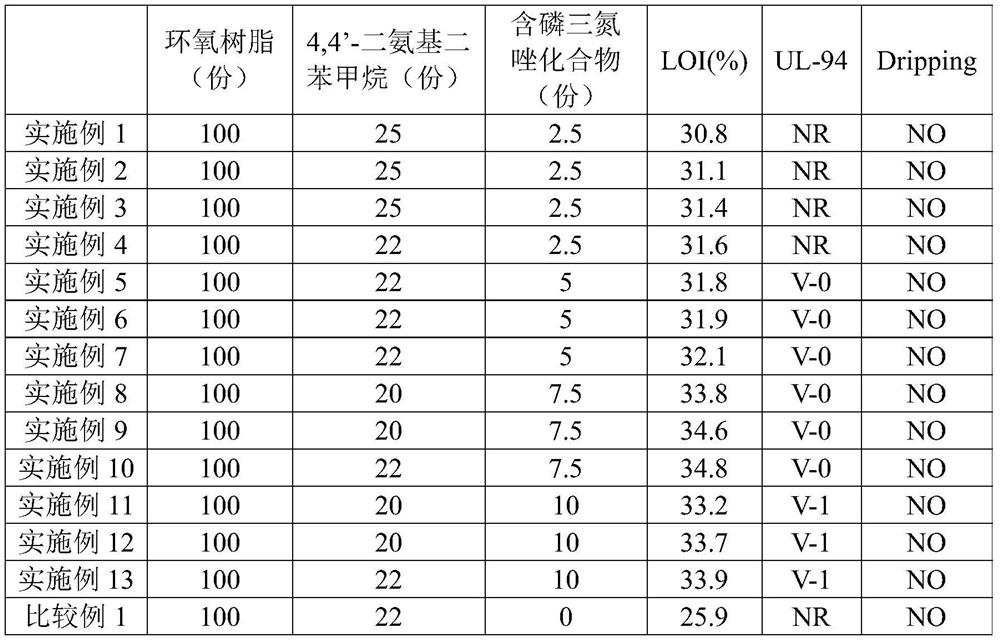

Intrinsic flame-retardant epoxy resin and preparation method thereof

InactiveCN113336920AWith flame retardant synergistic effectEfficient flame retardant propertiesEpoxyPolymer science

The invention discloses intrinsic flame-retardant epoxy resin and a preparation method thereof. The preparation method comprises the following steps: reacting epoxy resin with a reactive flame retardant at a certain temperature for a period of time; then adding a hardening agent, and stirring until a uniform solution is obtained; vacuumizing the epoxy solution to remove bubbles, and pouring the epoxy solution into a preheated mold for thermocuring; and after curing, naturally cooling to room temperature to obtain the intrinsic flame-retardant epoxy resin material. The intrinsic flame-retardant epoxy resin prepared by the method has excellent flame retardance, when the dosage of the reactive flame retardant in the epoxy resin is 2.5%, the oxygen index can reach 31.6%, and when the dosage of the reactive flame retardant in the epoxy resin is 5%, the vertical combustion grade can pass the UL-94 V-0 grade, and compared with pure epoxy resin, the flame retardance is obviously improved.

Owner:FUJIAN NORMAL UNIV

An in-situ remediation method for heavy metal-contaminated soil

InactiveCN110076192BGood removal effectSmall particle sizeContaminated soil reclamationFiberSpinning

The invention discloses an in-situ repair method for heavy metal polluted soil; chitosan and iron salt are mixed to prepare spinning solution, and chitosan / zero-valent nano-iron composite fiber is obtained through electrostatic spinning, and then passed through a twisting machine Twist with glass fiber to make a composite adsorption rope with heavy metal adsorption and reduction ability and a certain strength, and make it into a net, bury it in the soil polluted by heavy metals, take it out after a period of time, and complete the in-situ adsorption and removal of heavy metals in the soil . This method realizes the in-situ remediation of heavy metal-contaminated soil, is environmentally friendly, efficient, and easy to operate, and overcomes the disadvantage that traditional adsorption materials are difficult to separate from the soil.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com