Device and method for preparing metal surface microarray through ultrasonic energy field assisted laser rapid melting

A metal surface and microarray technology, which is applied in the field of laser processing and laser surface micromolding, can solve the problems of difficult microarray structure and low processing efficiency, and achieve the effect of high material utilization rate, high molding efficiency and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

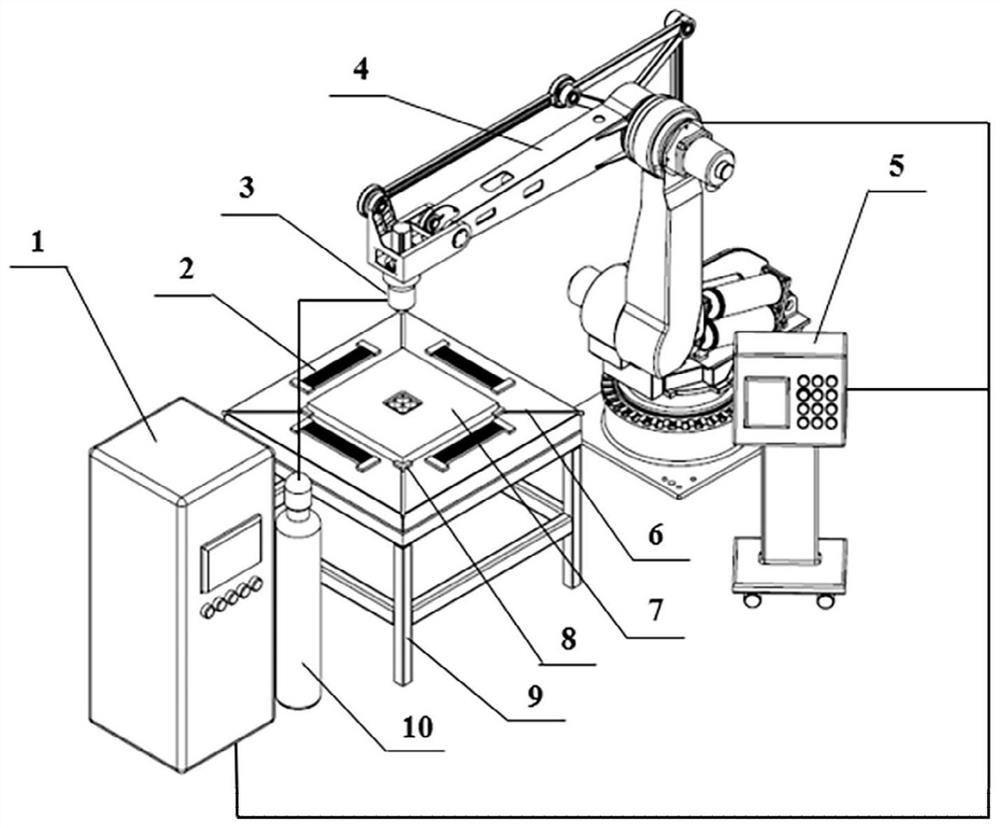

[0038] Such as figure 1 As shown, the metal surface microarray molding device prepared by surface acoustic wave laser rapid fusion of the present invention includes a laser 1, an interdigital transducer 2, a laser head 3, a mechanical arm 4, a control panel 5, and a bevel gear 6, Metal sample 7, jaws 8, workbench 9, protective gas device 10.

[0039] The laser forming equipment includes a laser 1, a laser head 3, a mechanical arm 4, a control panel 5 and a shielding gas device 10, which are used to generate a high-energy beam to heat a metal sample to produce a metal melt.

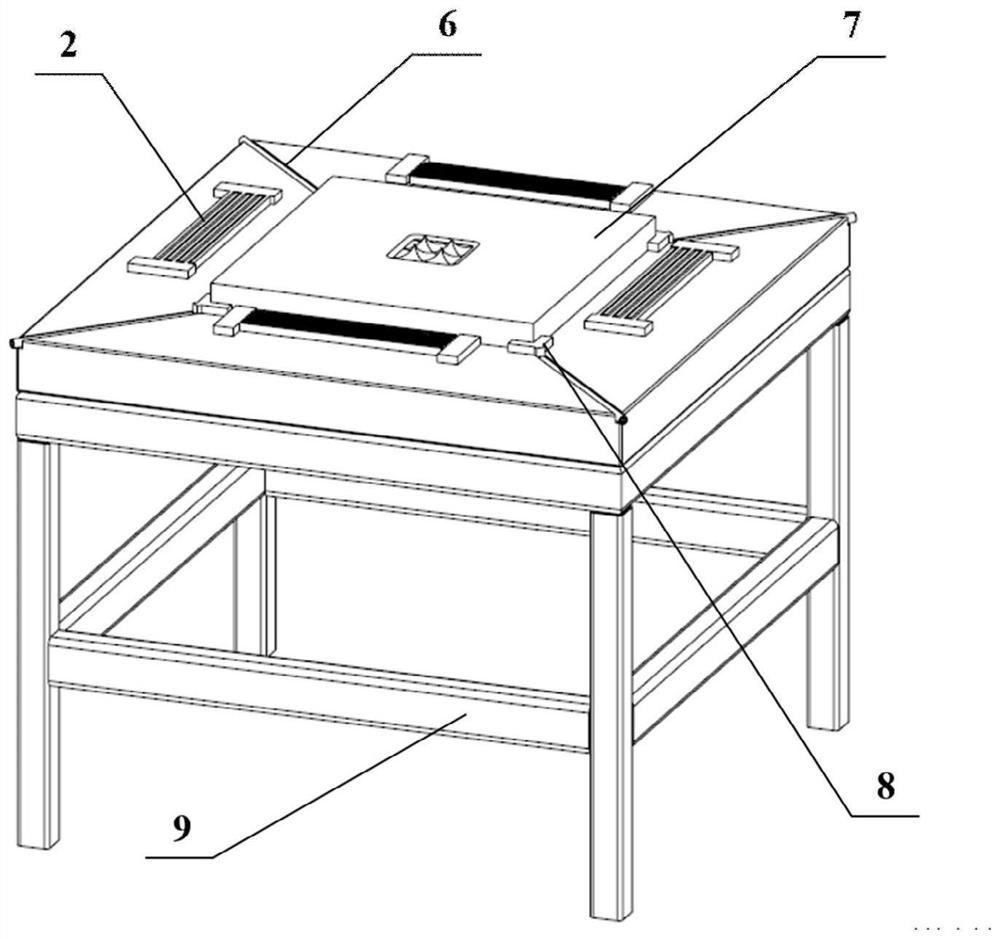

[0040] The surface acoustic wave workbench includes an interdigital transducer 2, a bevel gear 6, a metal sample 7, a claw 8 and a workbench 9, and its upper end surface is square; it is used to make the metal melt generate ideal Microarray structure.

[0041] The laser head is a variable spot lens group, which can change the size and length ratio of the spot during the melting process, and can provide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com