A kind of preparation method of non-halogen flame retardant containing phosphorus and molybdenum

A flame retardant, non-halogen technology, applied in the field of preparation of phosphorus and molybdenum-containing non-halogen flame retardants, can solve problems such as inability to use directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

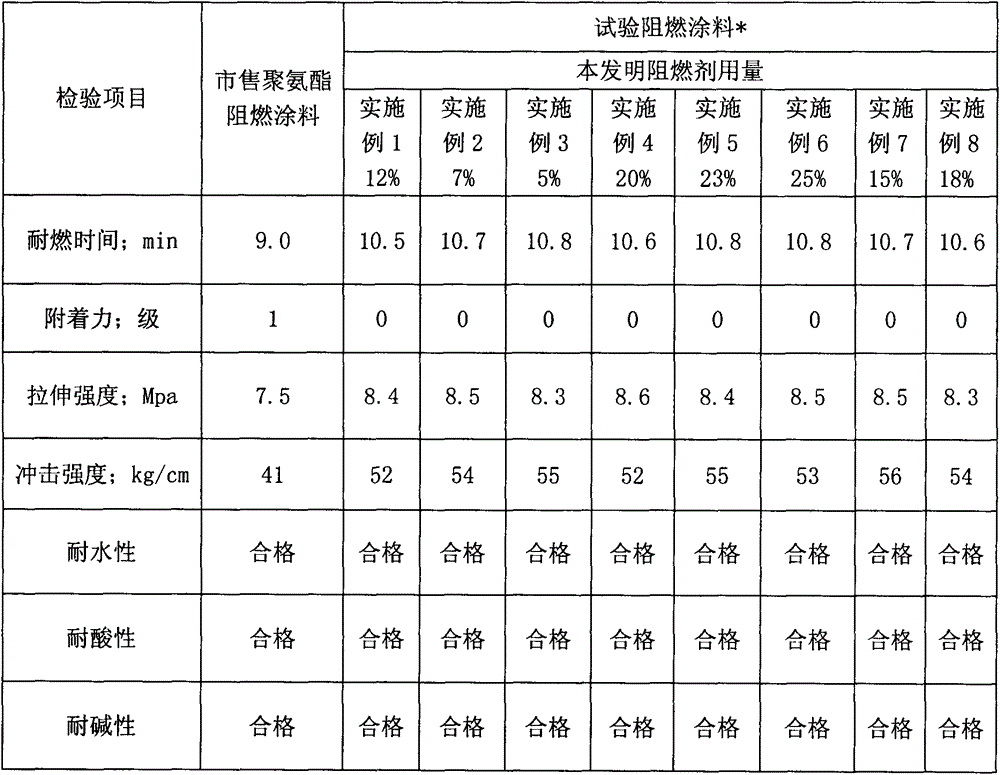

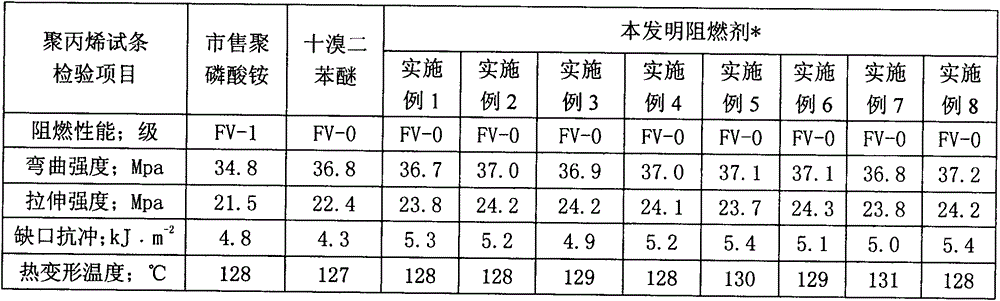

Examples

Embodiment 1

[0021] Add water to the stirring paddle in the reaction kettle, add 5 kg of zinc molybdate, 20 kg of magnesium hydroxide and 3 kg of silicon dioxide successively under stirring at room temperature. After 30 minutes, the temperature dropped to 15°C, added 122 kg of aluminum tripolyphosphate, and continued to stir for 30 minutes. After the material was centrifuged and dehydrated, it was directly added to the dispersing tank before drying, with 0.15 kg of dilute alcohol diluted with 1:1. Vinyl tris(b-methoxyethoxy)silane is modified, and then crushed, weighed and packaged to form a product.

Embodiment 2

[0023] Add water to the stirring paddle into the reaction kettle, heat to 80°C, then add 30 kg of zinc molybdate, 15 kg of magnesium hydroxide and 10 kg of silicon dioxide in sequence under stirring. When the temperature drops to 55°C, add 95 kg of aluminum tripolyphosphate and continue to stir for 30 minutes. After the material is centrifuged and dehydrated, directly add 0.75 kg of γ-ammonia diluted with 1:1 ethanol to the dispersion tank before drying. Propyltriethoxysilane is modified, and then crushed, weighed and packaged to form a product.

Embodiment 3

[0025] Add water to the stirring paddle in the reaction kettle, after heating to 55°C, add 15 kg of zinc molybdate, 45 kg of magnesium hydroxide and 15 kg of silicon dioxide successively under stirring. When the temperature drops to 30°C, add 75 kg of aluminum tripolyphosphate and continue to stir for 30 minutes. After the material is centrifuged and dehydrated, directly add 0.35 kg of vinyl trimethyl phosphate diluted with 1:1 ethanol to the dispersion tank before drying. Oxysilane is modified, and then crushed, weighed and packaged to form a product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com