A kind of post-grouting material of industrial waste multi-component composite shield tunnel wall and its preparation method

A multi-component composite and shield tunneling technology, which is applied in the field of engineering materials, can solve the problems of inert steel slag powder that cannot be solidified and hardened, high flow loss over time, and fast coagulation time, so as to achieve continuous growth in late strength, high early strength, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

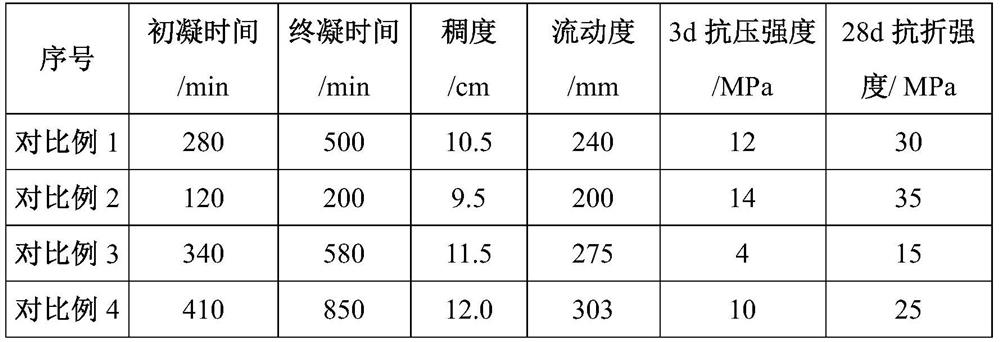

Examples

Embodiment 1

[0021] A method for preparing grouting material behind the wall of an industrial waste multi-component composite shield tunnel, comprising the following steps:

[0022] (1) adding sodium hydroxide in sodium silicate and adjusting to modulus is the modified sodium silicate solution of 1.4, and the mass ratio of sodium silicate solution and water press is 0.35;

[0023] (2) Add 80 parts of water to the modified sodium silicate solution, configure the alkaline activator solution, seal it with a polyethylene film, and cool it for later use;

[0024] (3) Take by weighing 50 parts of I grade C class fly ash, 10 parts of S95 grade blast furnace slag micropowder, 10 parts of inert steel slag micropowder, 150 parts of fine sand (river sand with mud content<1%) that modulus is 1.5, 1 part of FDN-C nano-based superplasticizer, 0.01 part of retarder sodium gluconate, then put it into a mixer and stir evenly, and stir at 140r / min for 3min;

[0025] (4) Mix the uniformly stirred powder wit...

Embodiment 2

[0027] A method for preparing grouting material behind the wall of an industrial waste multi-component composite shield tunnel, comprising the following steps:

[0028] (1) adding sodium hydroxide in sodium silicate and adjusting to modulus is the modified sodium silicate solution of 1.8, and the mass ratio of sodium silicate solution and water press is 0.5;

[0029] (2) Add 120 parts of water to the modified sodium silicate solution, configure the alkaline activator solution, seal it with a polyethylene film, and cool it for later use;

[0030] (3) Take by weighing 70 parts of class II class C fly ash, 30 parts of S95 grade blast furnace slag micropowder, 30 parts of inert steel slag micropowder, 200 parts of fine sand with a modulus of 2.0 (river sand with mud content<1%), 2 parts of FDN-C nano-based superplasticizer, 0.5 part of retarder sodium gluconate, and then put it into a mixer and stir evenly, stirring at 140r / min for 3min;

[0031] (4) Mix the uniformly stirred pow...

Embodiment 3

[0033] A method for preparing grouting material behind the wall of an industrial waste multi-component composite shield tunnel, comprising the following steps:

[0034] (1) adding sodium hydroxide in sodium silicate and adjusting to modulus is the modified sodium silicate solution of 1.6, and the mass ratio of sodium silicate solution and water press is 0.43;

[0035] (2) Add 100 parts of water to the modified sodium silicate solution to configure the alkaline activator solution, seal it with a polyethylene film, and cool it for later use;

[0036] (3) Take by weighing 60 parts of I grade C class fly ash, 20 parts of S95 grade blast furnace slag micropowder, 20 parts of inert steel slag micropowder, 175 parts of fine sand (river sand with mud content<1%) that modulus is 1.7, 1.5 parts of FDN-C nano-based water reducer, 0.3 parts of retarder sodium gluconate, and then put it into a mixer and stir evenly, stirring at 140r / min for 3min;

[0037] (4) Mix the uniformly stirred pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com