Industrial water treatment system

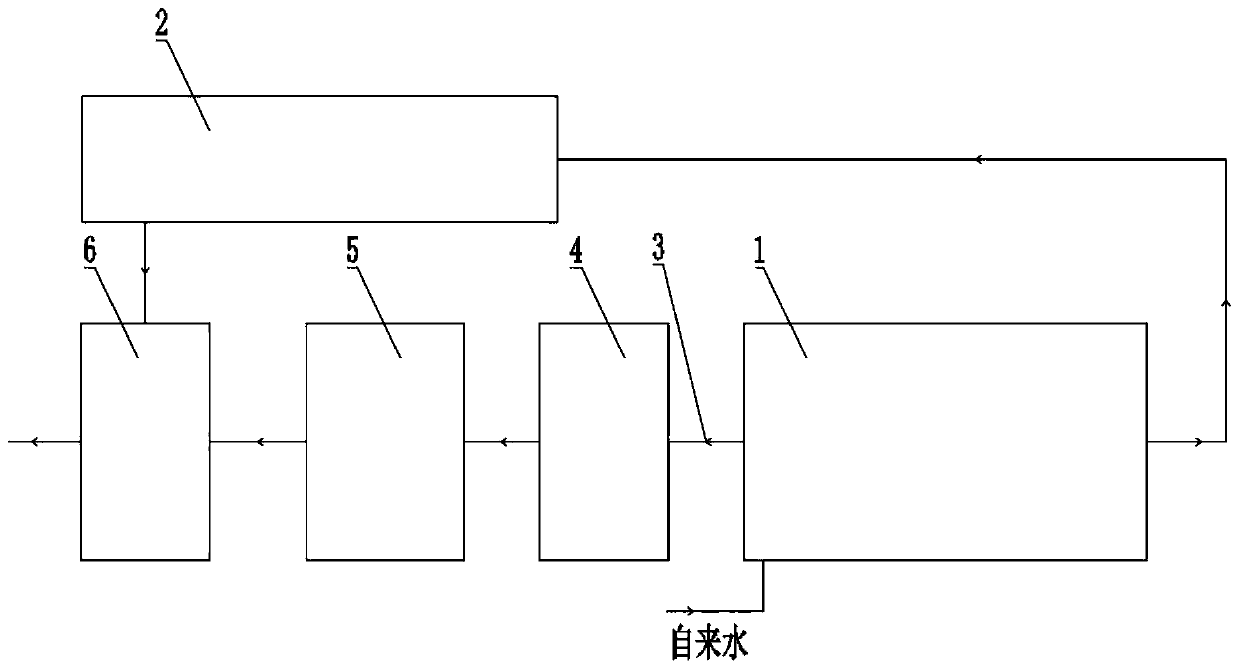

A treatment system and industrial water technology, applied in the field of pure water, can solve problems such as high requirements for treatment equipment, unutilized waste water, and waste of resources, and achieve the effects of reducing pollution, waste, and turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

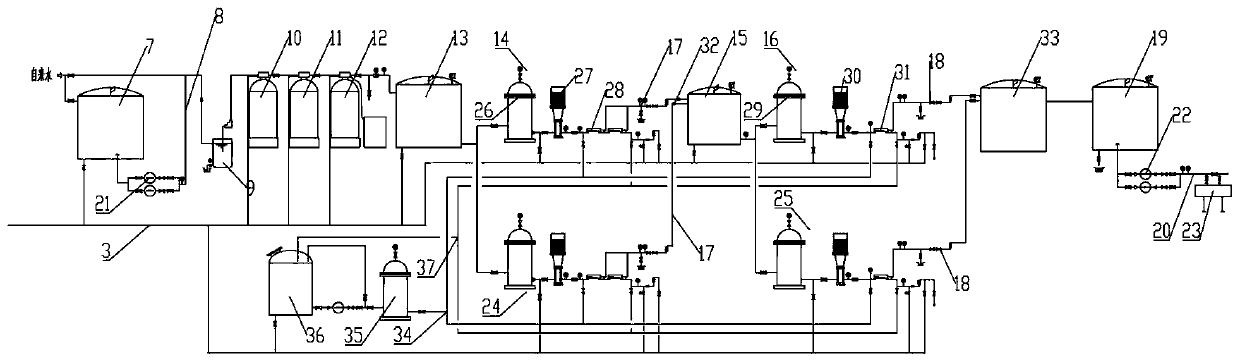

[0033] Water treatment process: pass tap water into the raw water tank 7 of the water treatment equipment 1, then transfer the water in the raw water tank 7 from the raw water tank 7 and then the raw water pump 21 into the flocculant dosing device 9, and the flocculant dosing device 9 injects water into the water Add flocculants to precipitate certain salt ions in the water, then pass the water through the quartz sand filter 10 for filtration, then transfer the filtered water into the activated carbon filter 11, and absorb the peculiar smell and flocculated precipitation in the water through the activated carbon etc., the activated carbon filter 11 is connected with a water softener 12, the water softener 12 further removes calcium and magnesium ions in the water, reduces the hardness of the water, and then divides the flow, and the two streams of water enter the first reverse osmosis device 14 and the third reverse osmosis device respectively 24, then adjust respectively throu...

Embodiment 2

[0035] Water treatment process: pass tap water into the raw water tank 7 of the water treatment equipment 1, then transfer the water in the raw water tank 7 from the raw water tank 7 and then the raw water pump 21 into the flocculant dosing device 9, and the flocculant dosing device 9 injects water into the water Add flocculants to precipitate certain salt ions in the water, then pass the water through the quartz sand filter 10 for filtration, then transfer the filtered water into the activated carbon filter 11, and absorb the peculiar smell and flocculated precipitation in the water through the activated carbon etc., the activated carbon filter 11 is connected with a water softener 12, the water softener 12 further removes calcium and magnesium ions in the water, reduces the hardness of the water, and then divides the flow, and the two streams of water enter the first reverse osmosis device 14 and the third reverse osmosis device respectively 24, then adjust respectively throu...

Embodiment 3

[0037] Water treatment process: pass tap water into the raw water tank 7 of the water treatment equipment 1, then transfer the water in the raw water tank 7 from the raw water tank 7 and then the raw water pump 21 into the flocculant dosing device 9, and the flocculant dosing device 9 injects water into the water Add flocculants to precipitate certain salt ions in the water, then pass the water through the quartz sand filter 10 for filtration, then transfer the filtered water into the activated carbon filter 11, and absorb the peculiar smell and flocculated precipitation in the water through the activated carbon etc., the activated carbon filter 11 is connected with a water softener 12, the water softener 12 further removes calcium and magnesium ions in the water, reduces the hardness of the water, and then divides the flow, and the two streams of water enter the first reverse osmosis device 14 and the third reverse osmosis device respectively 24, then adjust respectively throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com