Impurity removal and purification device for feldspar ceramic raw materials

A technology for feldspar ceramics and raw materials, which is applied in the field of feldspar ceramics raw material removal and purification devices, can solve the problems of inability to completely adsorb, limited high-quality ore, and inability to fully disperse, adsorb and discharge magnetic impurities, and saves the cost of layout and installation, and saves costs. Expenses, removal of impurities, environmental protection and efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

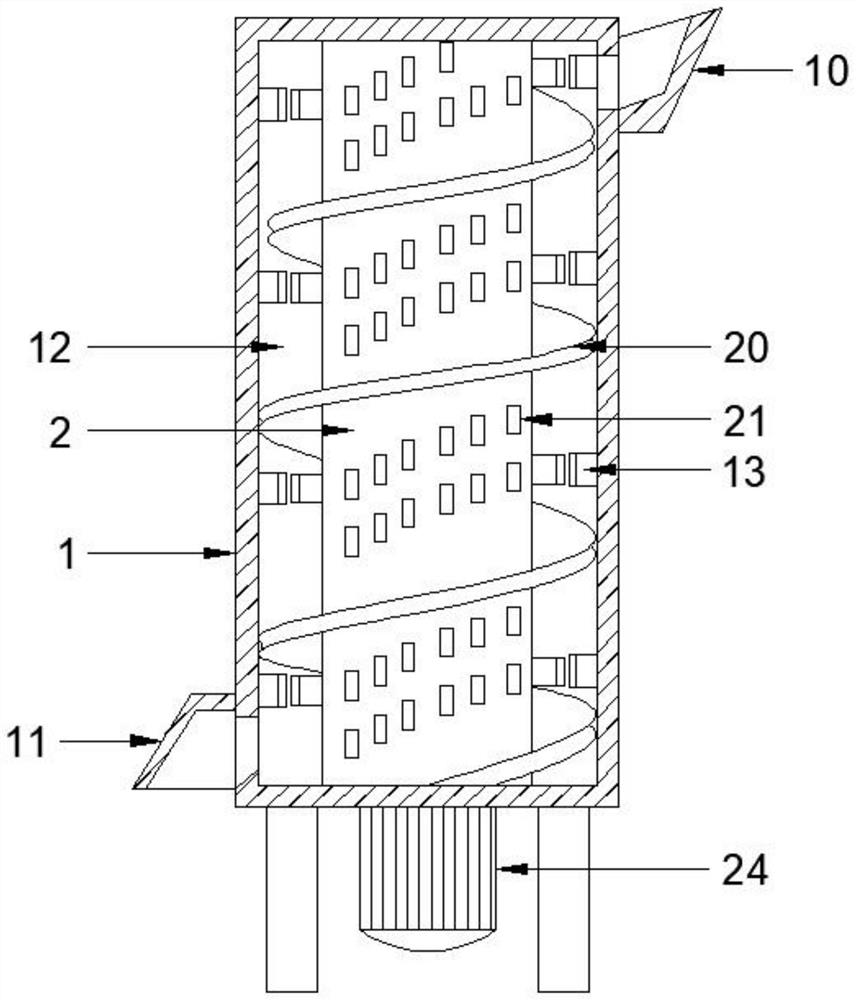

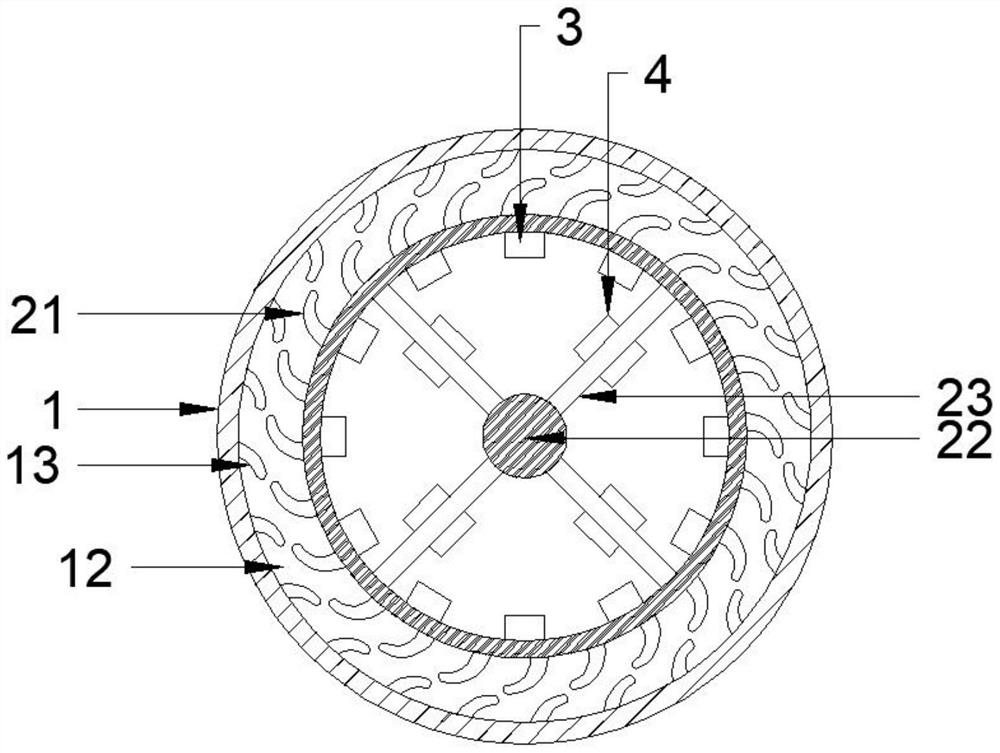

[0028] See Figure 1 ~ 2 In the embodiment of the present invention, a long stone ceramic feedstock is pure and purifies, including outer cylinder 1 and inner cylinder 2, and the inner cylinder 2 rotates within the axis of the outer cylinder 1, and the outer end of the outer cylinder 1 is provided for The drive in the inner cylinder 2 is rotated by a rotating mechanism that rotates the axis of the outer cylinder, and the outer wall of the inner cylinder 2 and the inner wall of the outer cylinder 1 is arranged to be used for the material cavity 12 for the feedstock, the outer cylinder 1 side walls. The feed port 10 and the discharge port 11 in communication with the material cavity 12 are opened respectively, and the outer wall of the inner cylinder 2 is slidable with the inner wall of the pusher 1 and the outer cylinder 1 inner wall. The inner wall of the inner cylinder 2 is mounted in the inner wall of the inner cylinder 12 in the inner wall of the inner cylinder 12, and the outer...

Embodiment 2

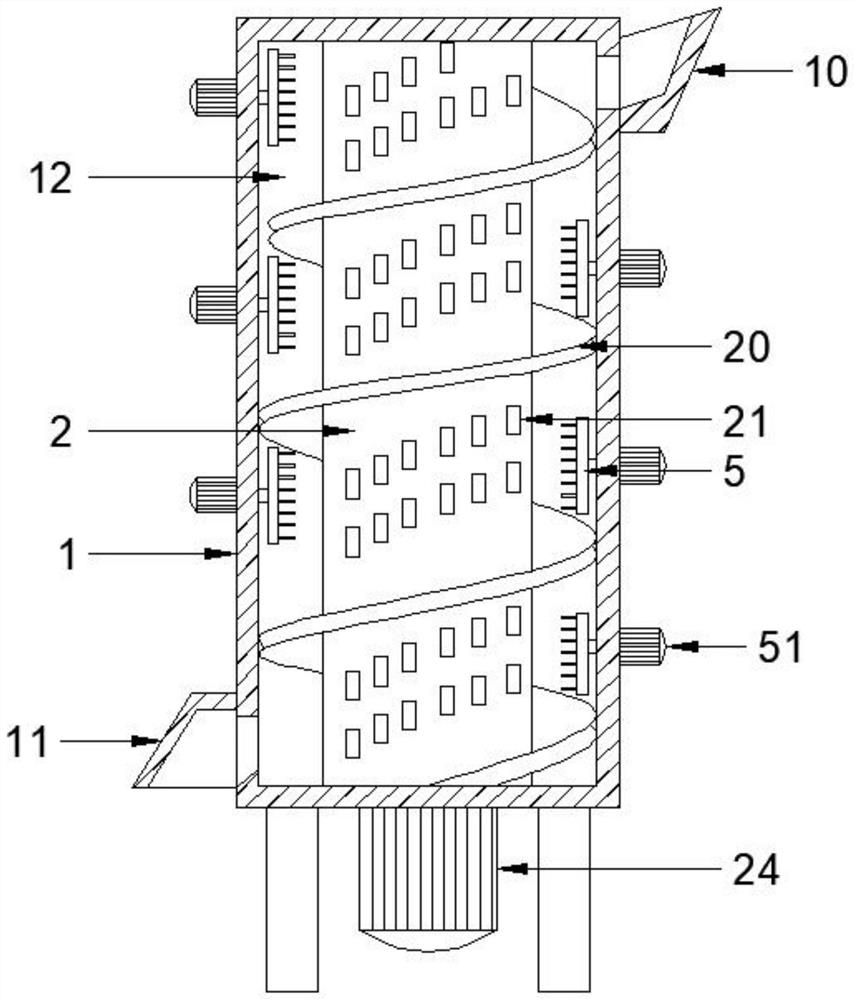

[0035] See Figure 3 ~ 5 The difference between the embodiment and the first embodiment is:

[0036] The turning material includes an inner die die 21 and a flush turntable 5 that is fixed to the outer wall of the inner cylinder 2 in the helical direction of the pusher 2, and the outer side wall of the inner cylinder 2. A plurality of outward internal feed sheets 21 are fixed vertically, and the turntable turntable 5 is mounted on the inner wall of the outer cylinder 1 by a rotating shaft perpendicular to the inner wall of the outer cylinder 1, and the outer wall of the outer cylinder 1 is mounted. The tip motor 51 that is rotated by the flush turntable 5 is driven, and the tip piezle tablets 50 toward the inner die pad 21 are mounted on the panel of the tubular die 5, and the inner donor sheet 21 is rotated in the inner cylinder 2. When the raw material attached to the outer wall of the inner cylinder 2 is smashed through the weight of the inner cylinder 2, the feedstock is contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com