Method for preparing foamed silver catalyst based on supercritical carbon dioxide foaming technology

A carbon dioxide, supercritical technology, applied in the preparation of amino hydroxyl compounds, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. performance, difficulty in obtaining syntactic foam, etc., to achieve good catalytic stability, maintain catalytic stability, and achieve the best market promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

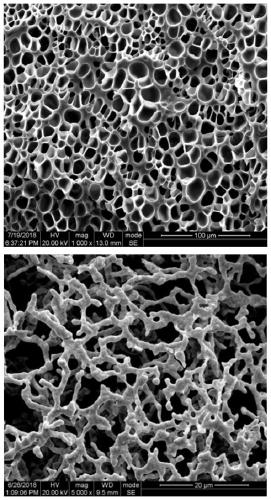

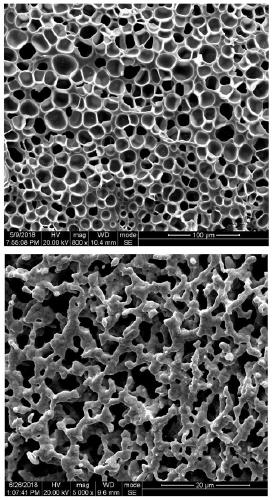

Image

Examples

Embodiment 1

[0043] The method for preparing foam silver catalyst based on supercritical carbon dioxide foaming technology, in parts by weight, comprises the following steps:

[0044] (1) Using 42 parts of silver nitrate (AgNO 3 ) and 100 parts of polyvinyl alcohol (PVA) were mixed and stirred for 60 hours. After the plasticization was complete, the mixed material obtained after plasticization was heated and melted, and the molding method was used to make it evenly mixed and shaped, and the prepared thickness was 2mm PVA / AgNO 3 Composite panels;

[0045] Wherein, the plasticizing system comprises the following components:

[0046] 60 parts of water,

[0047] 42 parts of silver nitrate;

[0048] (2) PVA / AgNO obtained in step (1) 3 Composite sheet prepared by supercritical carbon dioxide autoclave pressure foaming method to obtain PVA / AgNO 3 Composite foam material, wherein the process parameters of the supercritical carbon dioxide autoclave pressure foaming method are: the foaming pro...

Embodiment 2

[0053] The method for preparing foam silver catalyst based on supercritical carbon dioxide foaming technology, in parts by weight, comprises the following steps:

[0054] (1) Using 100 parts of silver nitrate (AgNO 3 ) and 100 parts of polyvinyl alcohol (PVA) were mixed and stirred for 72 hours. After the plasticization was complete, the mixed material obtained after plasticization was heated and melted, and the molding method was used to mix it evenly and shape it. The prepared thickness was 2mm PVA / AgNO 3 Composite panels;

[0055] Wherein, the plasticizing system comprises the following components:

[0056] 60 parts of water,

[0057] 100 parts of silver nitrate;

[0058] (2) PVA / AgNO obtained in step (1) 3 Composite sheet prepared by supercritical carbon dioxide autoclave pressure foaming method to obtain PVA / AgNO 3 Composite foam material, wherein the process parameters of the supercritical carbon dioxide autoclave pressure foaming method are: the foaming process pr...

Embodiment 3

[0064] The method for preparing foam silver catalyst based on supercritical carbon dioxide foaming technology, in parts by weight, comprises the following steps:

[0065] (1) Using 40 parts of silver nitrate (AgNO 3 ) and 100 parts of polyvinyl alcohol (PVA) were mixed and stirred for 48 hours. After the plasticization was complete, the mixed material obtained after plasticization was heated and melted, and the molding method was used to make it evenly mixed and shaped, and the prepared thickness was 1mm PVA / AgNO 3 Composite panels;

[0066] Wherein, the plasticizing system comprises the following components:

[0067] 40 parts of water,

[0068] 20 parts of ethylene glycol,

[0069] 40 parts of silver nitrate;

[0070] (2) PVA / AgNO obtained in step (1) 3 Composite sheet prepared by supercritical carbon dioxide autoclave pressure foaming method to obtain PVA / AgNO 3 Composite foam material, wherein the process parameters of the supercritical carbon dioxide autoclave pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com