Oxidized partially hydrogenated oil

A technology of oil and peroxide value, applied in fatty acid oxidation, edible oil/fat, fatty acid production, etc., can solve the problems of losing unique hydrogenated aroma and flavor, reducing trans fatty acids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The above-mentioned oxidized and partially hydrogenated oil can be prepared by the following preparation method, the method comprising: partially hydrogenating the oil until the C18:2 trans isomer content reaches 10 to 60 wt% based on the fatty acid content of the entire composition; and Oxidation until a peroxide value of 8 to 350 meq / kg is reached.

[0040] The above-mentioned step of partially hydrogenating oil and fat and the step of oxidizing oil and fat are performed in any order. Preferably, the oil is first partially hydrogenated until the C18:2 trans isomer content reaches 10 to 60 wt% based on the fatty acid content of the entire composition, and then the resulting partially hydrogenated oil is oxidized until the peroxide value reaches 8 to 350meq / kg. Therefore, the above-mentioned oxidized and partially hydrogenated fats and oils are preferably prepared by partially hydrogenating fats and oils and oxidizing the resulting hydrogenated fats and oils. According...

Embodiment 1-16

[0064] [Example 1-16] (Preparation and evaluation of oxidized and partially hydrogenated fats and oils)

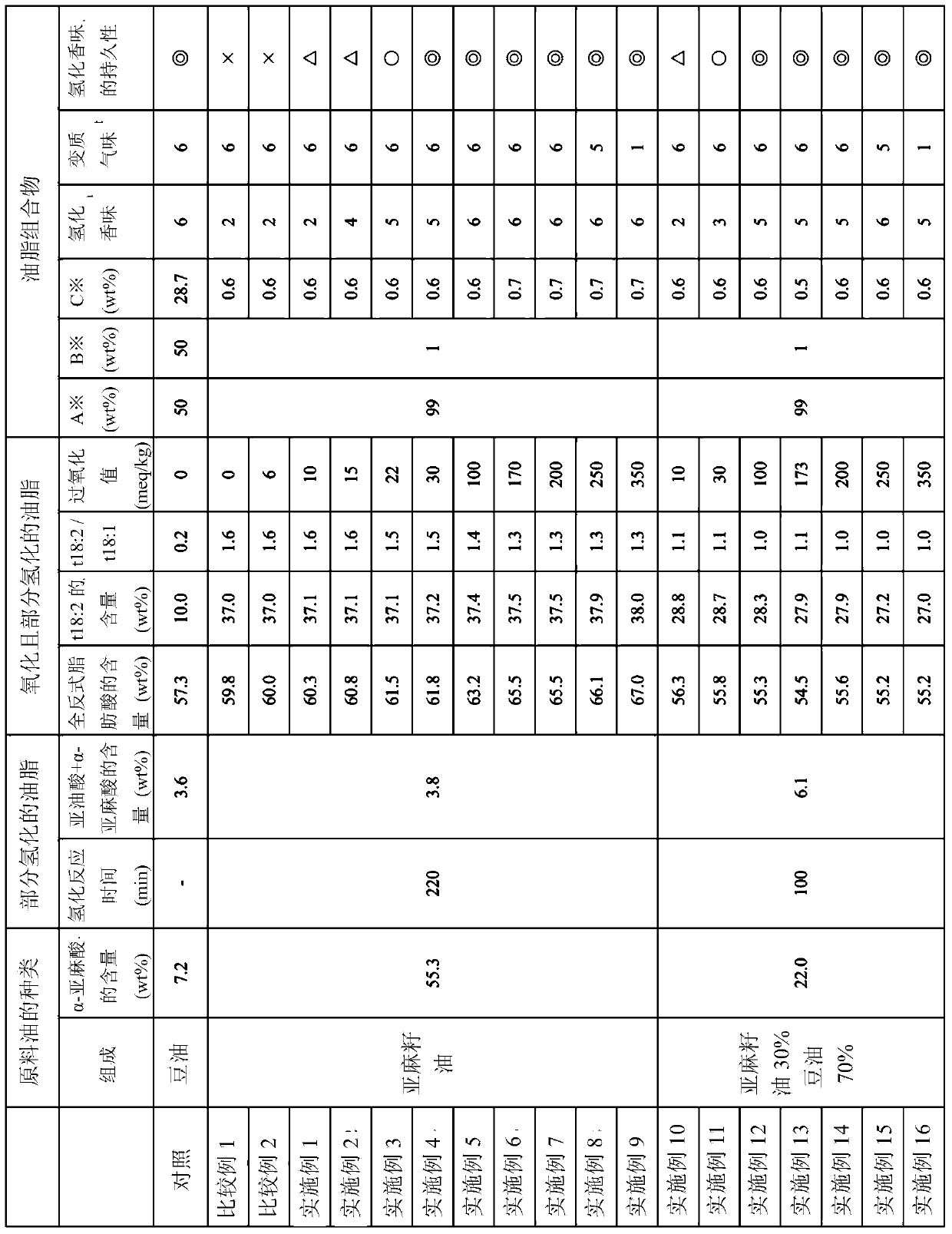

[0065] Change the peroxide value of two oxidized and partially hydrogenated oils with t18:2 contents of 37.0wt% and 28.8wt%, respectively, and detect the effect of peroxide value on hydrogenated aroma.

[0066] 1. Preparation of oxidized and partially hydrogenated oils

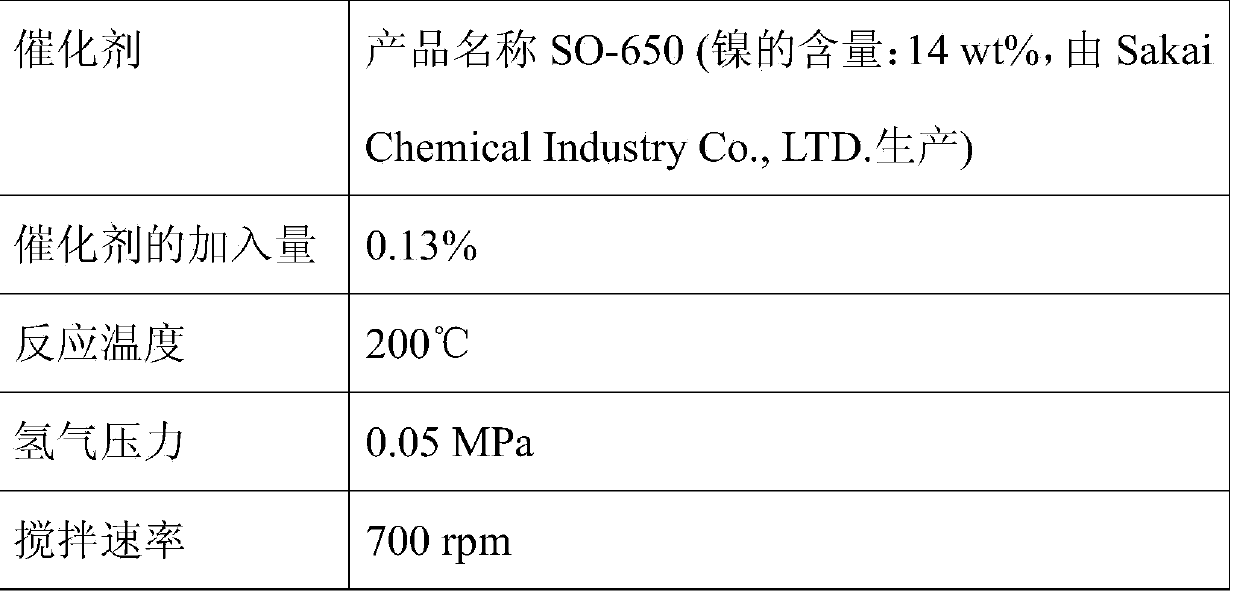

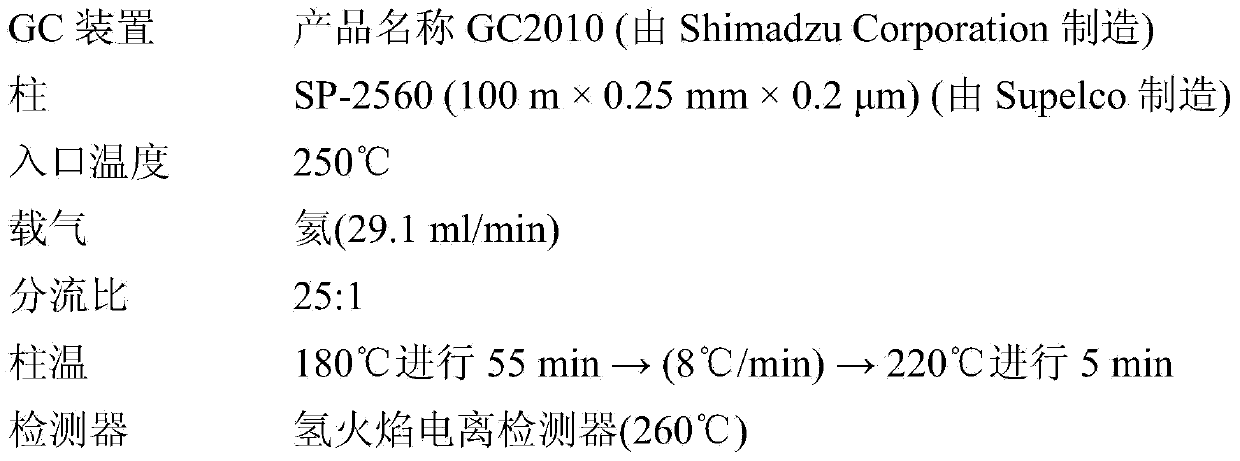

[0067] Under the conditions shown in Table 1, 700 g of linseed oil (manufactured by J-OIL MILLS, INC.) containing 55.3 wt% α-linolenic acid based on the constituent fatty acid content was partially hydrogenated for 220 minutes. This partial hydrogenation treatment is repeated several times until the desired amount of partially hydrogenated oil is produced. Also, under the conditions shown in Table 1, 700 g of soybean oil (product name: Daizu Sirasameyu (soybean soybean oil) containing 7.2 wt% α-linolenic acid based on the constituent fatty acid content was mixed with the above-mentioned linseed oil at a w...

Embodiment 17-24

[0112] [Example 17-24] (Content of C18:2 trans isomer)

[0113] The following procedure was used to examine the effect of t18:2 content on hydrogenated aroma in oxidized and partially hydrogenated fats and oils with a peroxide value of 170 meq / kg.

[0114] 1. Preparation of oxidized and partially hydrogenated oils

[0115] Except that under the same conditions as shown in Table 1, 700 g of the above-mentioned linseed oil or perilla seed oil (containing 65.4 wt% of α-linolenic acid based on the total composition fatty acid content, produced by OHTA OIL MILL CO., LTD. ) hydrogenation for various reaction times shown in Table 3, and then oxidize it until the peroxide value reaches beyond 170meq / kg, prepare oxidized and partially hydrogenated fats and oils with the same steps as described in Example 1. Table 3 shows the fatty acid composition of each of the obtained fats and oils.

[0116] 2. Preparation and evaluation of oil composition

[0117] The obtained oxidized and parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com