Fresh shrimp flavor sauce and preparation method thereof

A seasoning sauce and flavor technology, which is applied in the field of fresh shrimp characteristic flavor sauce and its preparation, can solve the problems of similar method steps, single means, lack of flavor and nutrient content, etc., achieve small loss of nutrients, solve environmental pollution, The effect of reducing the content of trans fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

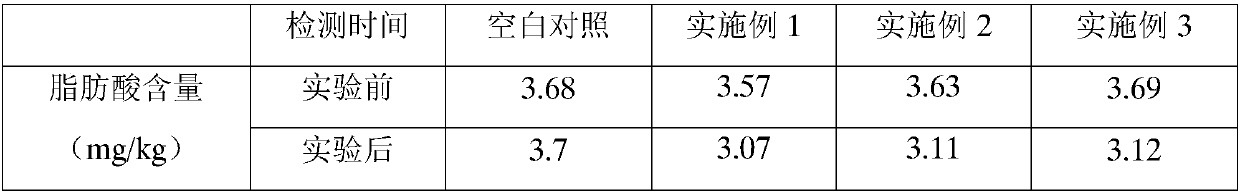

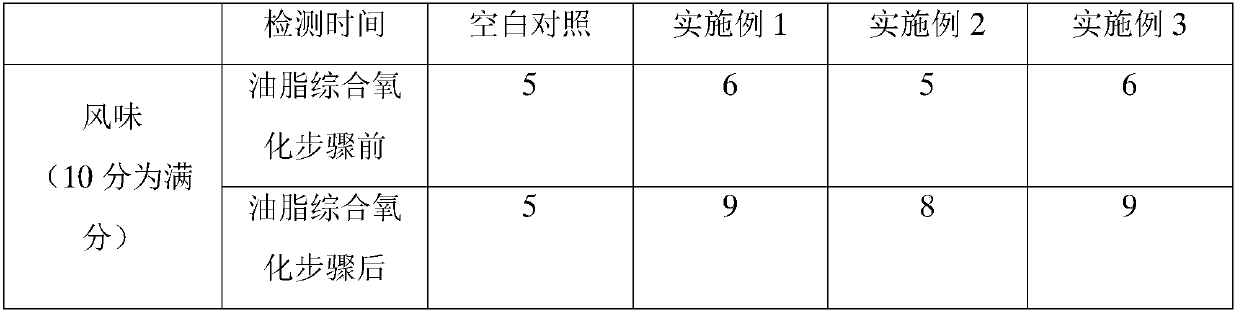

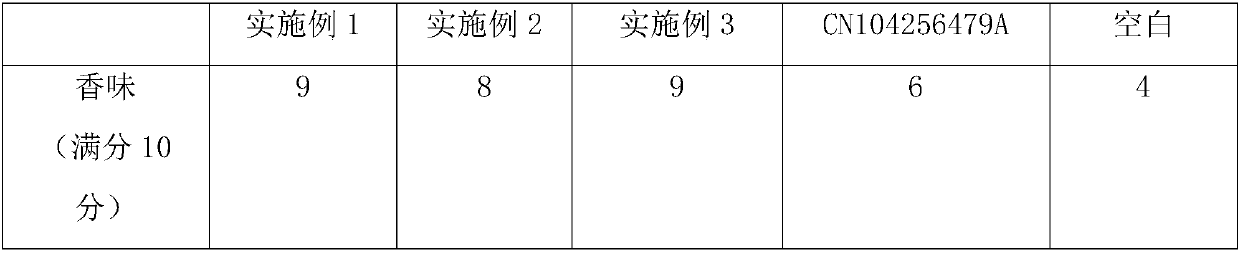

Examples

Embodiment 1

[0025] A fresh shrimp characteristic flavor seasoning sauce and a preparation method thereof, comprising the following steps

[0026] Step 1 comprehensive oxidation of oil

[0027] 50mL soybean oil, 100mL purified water, 8g salt, 8g sucrose, 100g shrimp processing residue (shrimp head and shrimp skin), 20g leek (cut into 0.5cm long segments), 20g ginger (cut into 0.5cm side length pieces). Take 50mL oil and heat it to 160°C in an iron pan, add 20g diced ginger and stir-fry for 10s, then add 100g shrimp processing residue and 8g sucrose, stir-fry for 40s, then add 20g leek segments and 100mL water, stir-fry for 1min, then add 8g salt, stir well, cool to room temperature, set aside.

[0028] Step 2 Biological enzymatic hydrolysis

[0029] Remove the chives from the sample of oil comprehensive oxidation, add water at a mass ratio of 1:1, mix evenly, and beat to obtain a slurry. Take 100 g of the slurry, and when heated to 50° C., add 0.2% animal protease and 0.3% flavor protea...

Embodiment 2

[0036] A fresh shrimp characteristic flavor seasoning sauce and a preparation method thereof, comprising the following steps

[0037] Step 1 comprehensive oxidation of oil

[0038]40mL of soybean oil, 80-120 of purified water, 6g of salt, 6g of sucrose, 80g of shrimp processing residue (shrimp head and shrimp skin), 15g of leek (cut into 0.5cm long sections), 15g of ginger (cut into 0.5cm side length pieces) ). Heat 40mL of oil in an iron pan to 150°C, add 15g of diced ginger and stir-fry for 10s, then add 80g of shrimp processing residue and 6g of sucrose, stir-fry for 30s, then add 15g of leek segments and 80mL of water, stir-fry for 50s, then add 6g salt, stir well, cool to room temperature, set aside.

[0039] Step 2 Biological enzymatic hydrolysis

[0040] Remove the chives from the sample of oil comprehensive oxidation, add water at a mass ratio of 1:1, mix evenly, and beat to obtain a slurry. Take 100 g of the slurry, and when heated to 45° C., add 0.15% animal prot...

Embodiment 3

[0047] A fresh shrimp characteristic flavor seasoning sauce and a preparation method thereof, comprising the following steps

[0048] Step 1 comprehensive oxidation of oil

[0049] 60mL of soybean oil, 120mL of purified water, 10g of salt, 10g of sucrose, 120g of shrimp processing residue (shrimp head and shrimp skin), 25g of leek (cut into 0.5cm long segments), 25g ginger (cut into 0.5cm side length pieces). Take 60mL oil and heat it to 180°C in an iron pan, add 25g diced ginger and stir-fry for 15s, then add 120g shrimp processing residue and 10g sucrose, stir-fry for 50s, then add 25g leek segments and 120mL water, stir-fry for 70s, then add 10g salt, stir well, cool to room temperature, set aside.

[0050] Step 2 Biological enzymatic hydrolysis

[0051] Remove the chives from the sample of oil comprehensive oxidation, add water at a mass ratio of 1:1, mix evenly, and beat to obtain a slurry. Take 100 g of the slurry, and when heated to 60° C., add 0.3% animal protease a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com