Process for preparing sterol ester of fatty acid for food

A technology of fatty acid ester and manufacturing method, which is applied in the direction of fatty acid esterification, edible oil/fat, fatty acid production, etc., can solve the problems of unoptimized safety, high price, no consideration of quality and safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

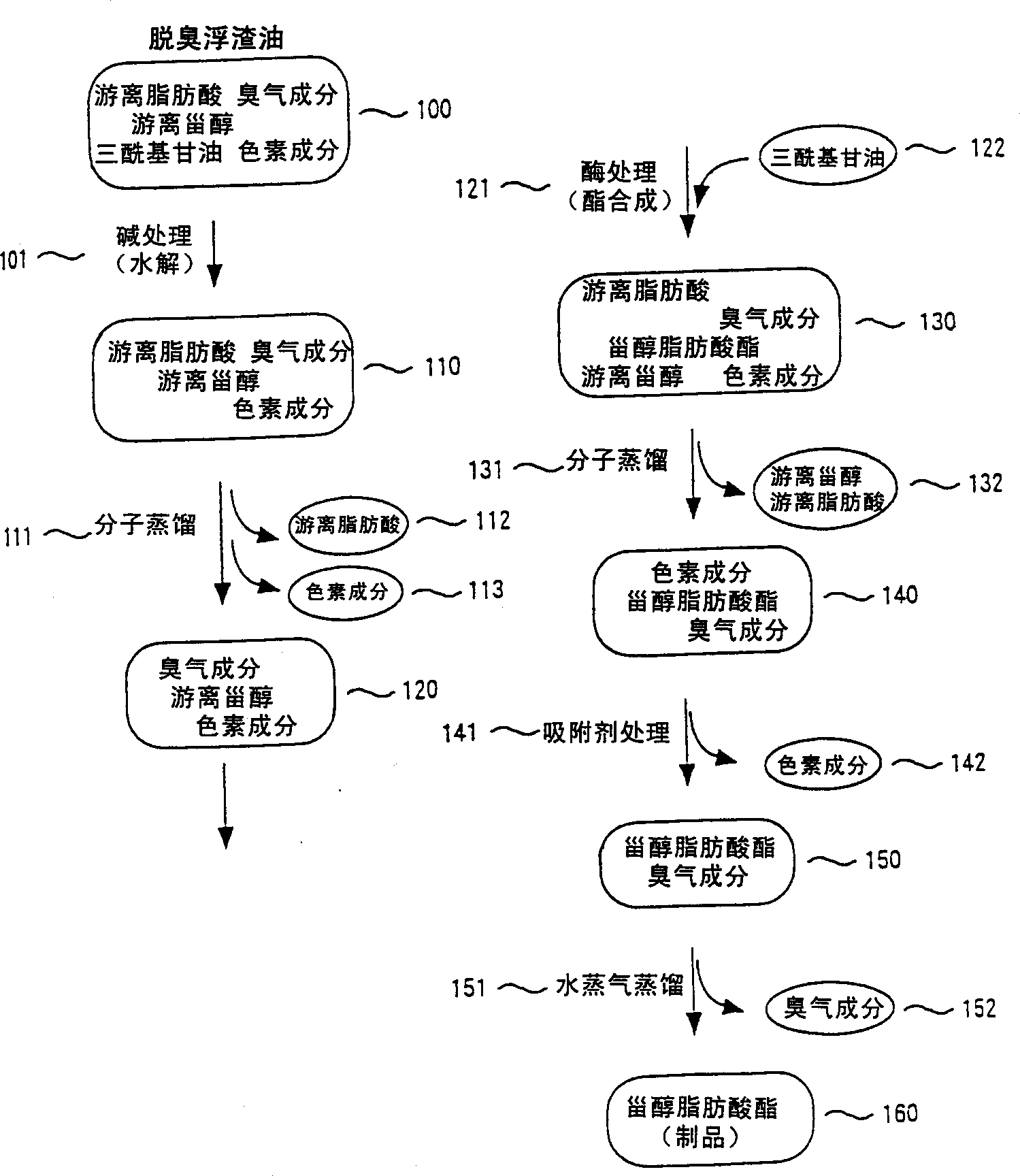

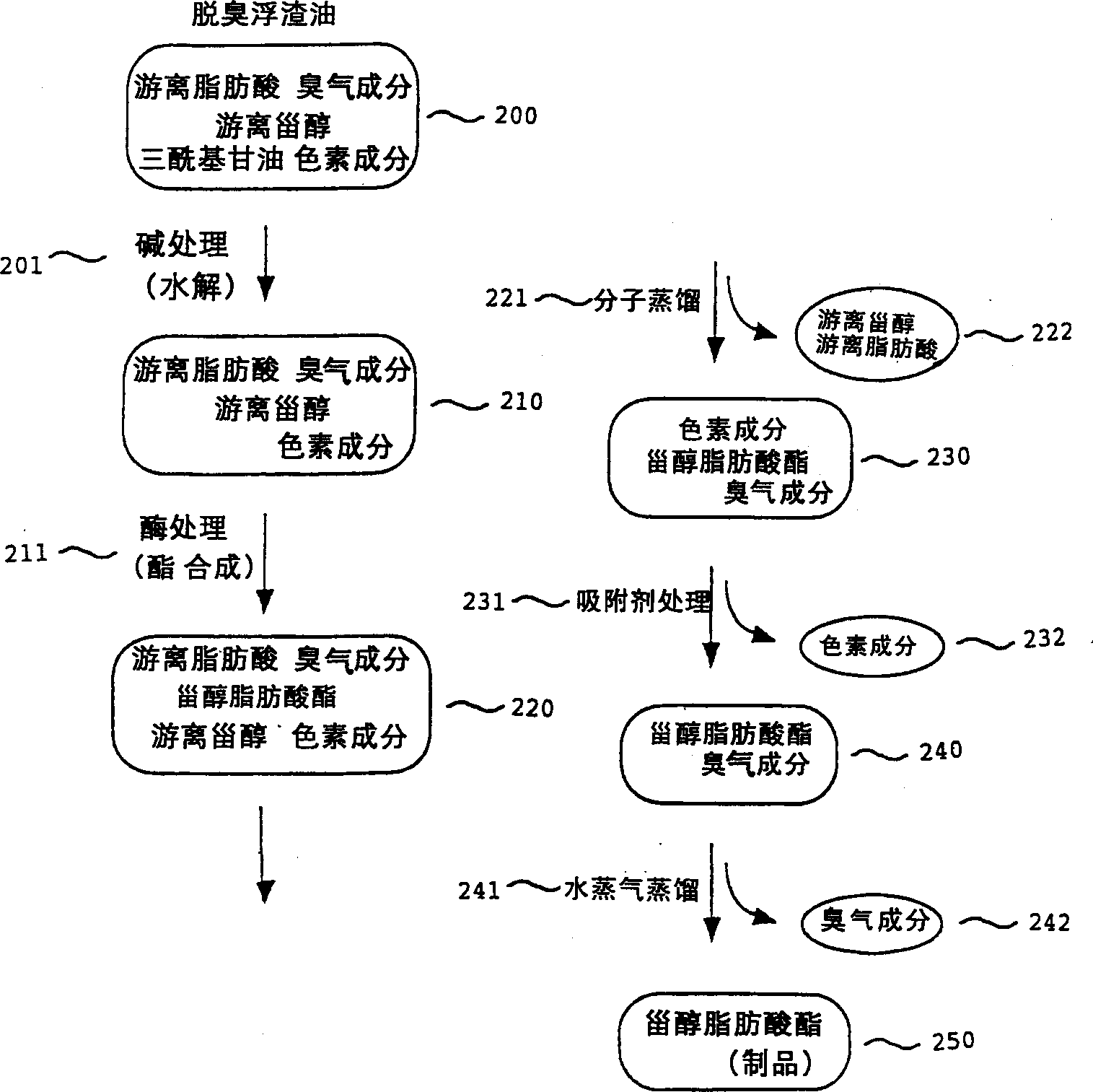

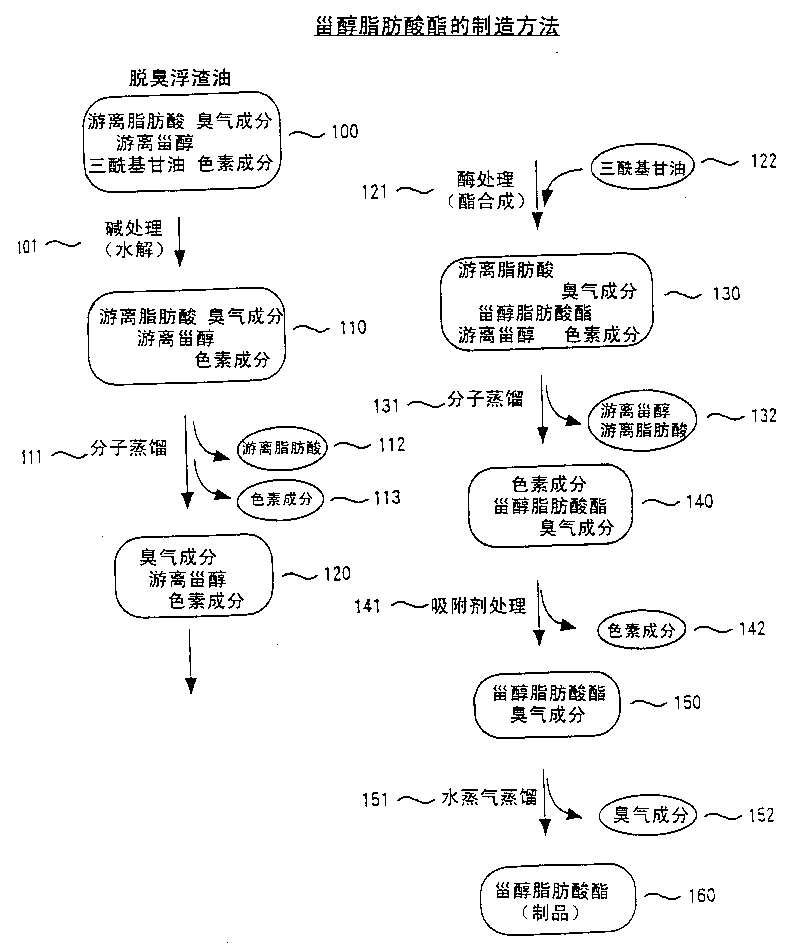

Method used

Image

Examples

Embodiment 1

[0200] 100 g of water was added to 200 g of soybean deodorized scum oil (sterol content 13% by weight), and while mixing at 40° C., lipase powder (360,000 units / g) derived from Candida was added (Lipase OF, Meito Sangyo Co., Ltd.) 2.0 g. After performing the reaction while stirring at 40° C. for 24 hours, enzyme inactivation was performed by stirring at 80° C. for 30 minutes. After performing dehydration treatment at 80° C. under reduced pressure, 1.0 g of diatomaceous earth was added, stirred, and filtered to remove enzyme protein. Next, molecular distillation was carried out using a centrifugal molecular distillation apparatus with a vacuum degree of 1.5 Pa, an evaporation surface temperature of 230° C., and a flow rate of 2.0 L / hour to remove impurities mainly composed of free fatty acids to obtain 33 g of sterol fatty acid esters. Then, as an adsorbent treatment, hexane in an amount 5 times the amount of the remaining components was added, mixed, 20% of activated clay was...

Embodiment 2

[0203] 50 g of water was added to 200 g of soybean deodorized scum oil (sterol content 13% by weight), and while mixing at 40° C., heat-resistant lipase powder (10,000 units / g) derived from Rhizopus was added (タリパゼ, Tian Bian Pharmaceutical Co., Ltd.) 3.0 g. After performing the reaction while stirring at 50° C. for 24 hours, the enzyme was inactivated by stirring at 90° C. for 30 minutes. After performing dehydration treatment at 80° C. under reduced pressure, 1.0 g of diatomaceous earth was added, stirred, and filtered to remove enzyme protein. Next, molecular distillation was performed using a centrifugal molecular distillation apparatus with a vacuum degree of 1.5 Pa, an evaporation surface temperature of 230° C., and a flow rate of 2.0 L / hour to remove impurities mainly including free fatty acids to obtain 31 g of sterol fatty acid esters. Then, as an adsorbent treatment, hexane in an amount 5 times the amount of the remaining components was added, mixed, 20% of silica g...

Embodiment 3

[0205] 100 g of water was added to 200 g of rapeseed deodorized scum oil (sterol content 8%), and while mixing at 40° C., lipase powder (360,000 units / g) derived from Candida was added (Lipase OF, Meito Sangyo Co., Ltd.) 2.0 g. After performing the reaction while stirring at 40° C. for 24 hours, enzyme inactivation was performed by stirring at 80° C. for 30 minutes. After performing dehydration treatment at 80° C. under reduced pressure, 1.0 g of diatomaceous earth was added, stirred, and filtered to remove enzyme protein. Next, molecular distillation was carried out using a centrifugal molecular distillation apparatus at a vacuum degree of 1.5 Pa, an evaporation surface temperature of 230° C., and a flow rate of 2.0 L / hour to remove impurities mainly composed of free fatty acids to obtain 28 g of sterol fatty acid esters. Then, as an adsorbent treatment, hexane in an amount 5 times the amount of the remaining components was added, mixed, 20% of activated carbon relative to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com