Production method of refined colza oil, refined colza oil produced by using the method, and acid emulsion food containing the above mentioned colza oil

A manufacturing method and technology of rapeseed oil, applied in the fields of fat oil/fat refining, food science, edible oil/fat, etc., can solve the problems of reducing the content of trans fatty acids, etc., and achieve the effect of reducing the content of trans fatty acids and inhibiting the reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

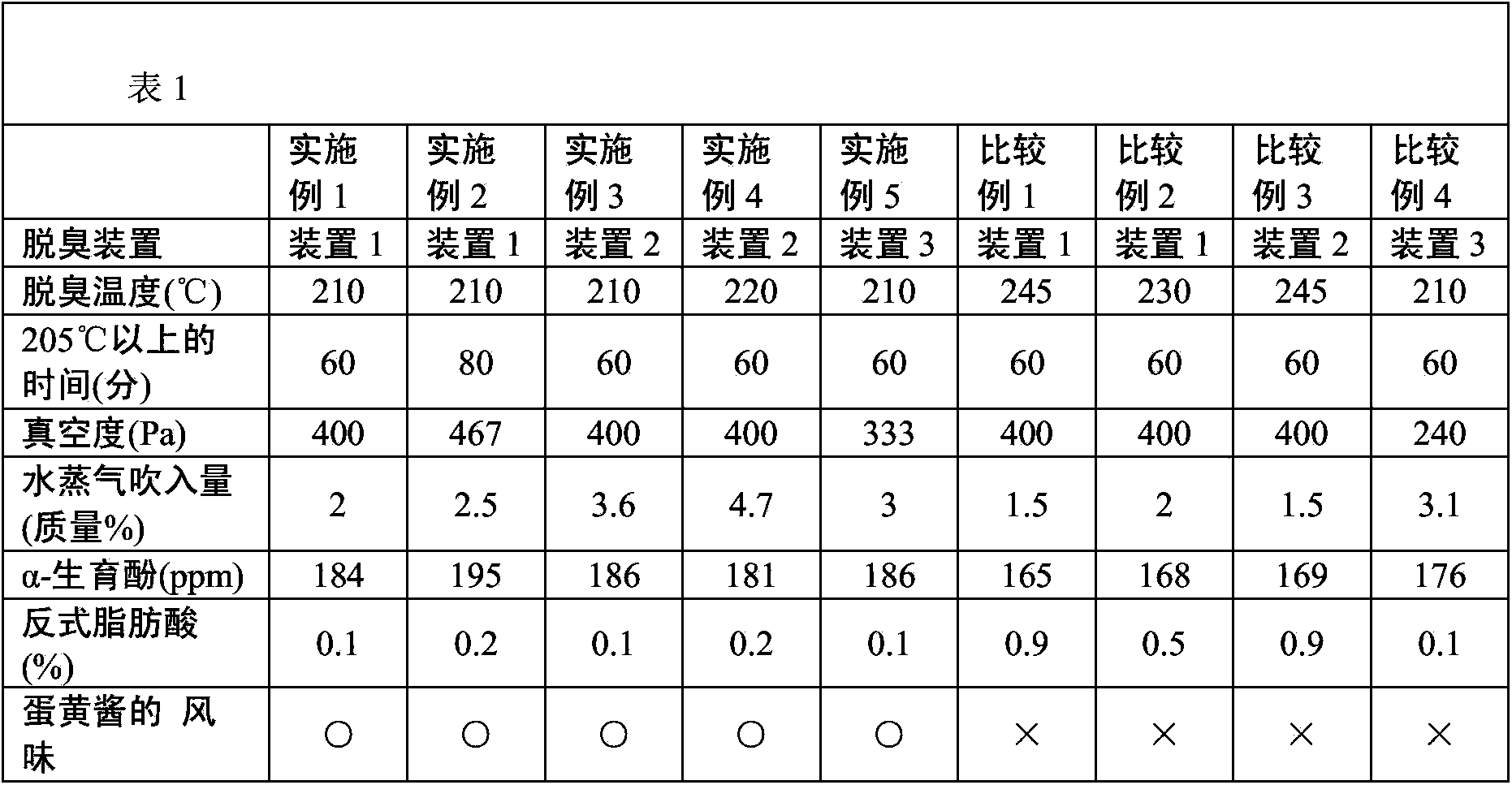

Embodiment 1~5、 comparative example 1~4

[0059] Using a deodorizer, the decolorized rapeseed oil (manufactured by Nisshin Oiliyo Group Co., Ltd.) was deodorized under the conditions described in Table 1 to obtain the purified rapeseed oil of each Example and Comparative Example.

[0060] The deodorizing device used is any one of the following devices. The girdler-type deodorizer 1 is a continuous deodorizer, and has a structure in which all the trays are connected together by piping provided between the trays, and fats and oils are continuously supplied into the apparatus. The girdler-type deodorizer 2 is a semi-continuous deodorizer, and has a structure in which valves are provided on each tray, so that fats and oils between the trays are less likely to mix.

[0061] Device 1: girdler type deodorization device 1

[0062] Device 2: girdler type deodorization device 2

[0063] Device 3: batch type deodorization device

[0064] In addition, in the following table, "the time of 205 degreeC or more" means the total ti...

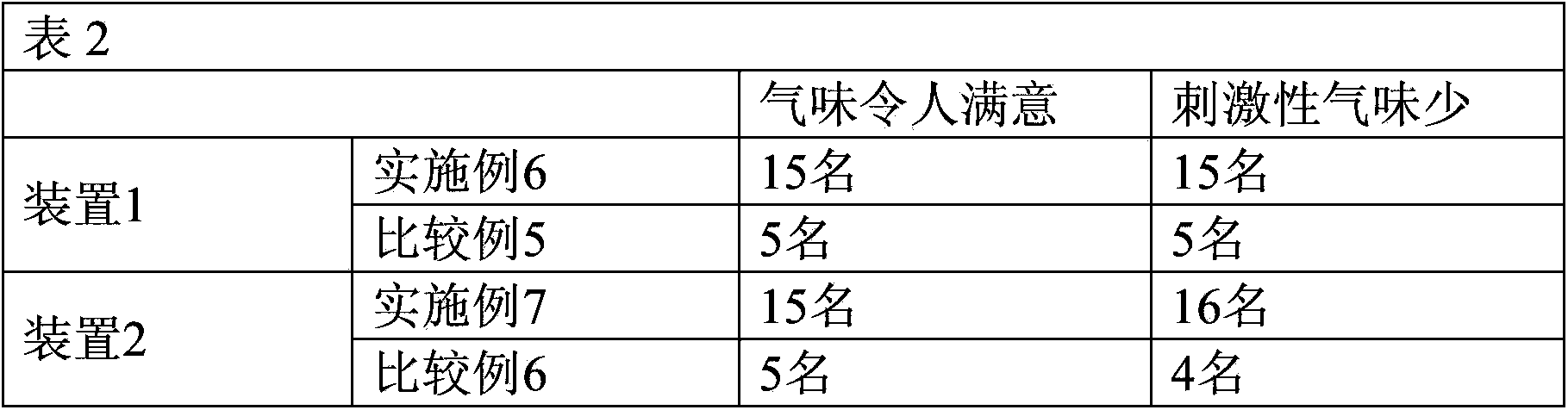

Embodiment 6 and Embodiment 7

[0082] [Example 6 and Example 7, Comparative Example 5 and Comparative Example 6]

[0083] The decolorized rapeseed oil (manufactured by Nisshin Oillio Group Co., Ltd.) was deodorized under the following conditions using a deodorizer to obtain purified rapeseed oils in Examples and Comparative Examples. In addition, "apparatus 1" and "apparatus 2" mentioned below mean the same apparatuses as "apparatus 1" and "apparatus 2" used in Examples 1-5 and Comparative Examples 1-4, respectively.

[0084] Example 6 and Example 7: "Apparatus 1" was used in Example 6, "Apparatus 2" was used in Example 7, at 220°C, vacuum degree 400Pa (3torr), 60 minutes, water vapor blowing amount 3.4 The decolorized rapeseed oil was brought into contact with water vapor under the condition of mass %. This step corresponds to the "contacting step" in the present invention.

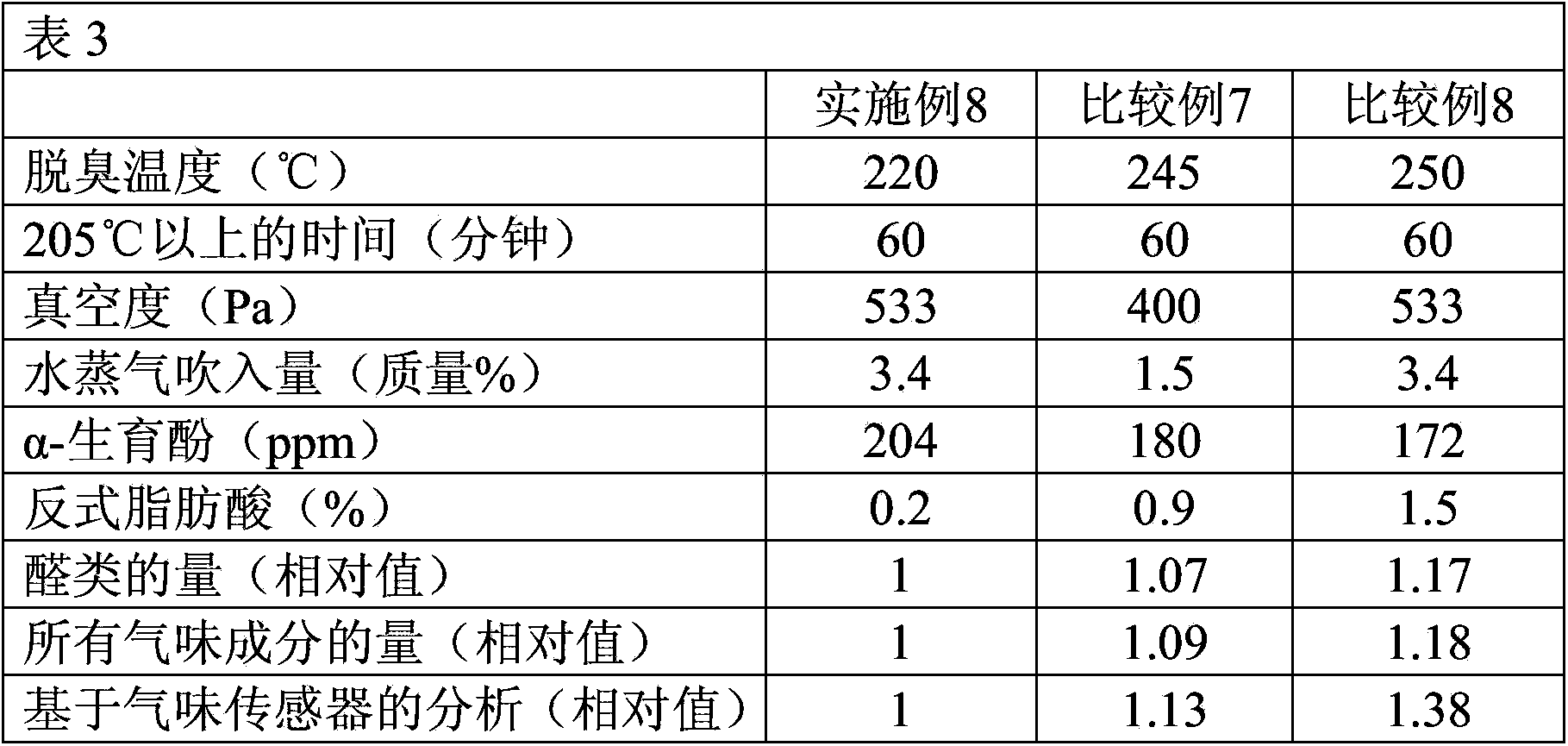

Embodiment 8、 comparative example 7 and comparative example 8

[0093] Using a deodorizer, the decolorized rapeseed oil (manufactured by Nisshin Oiliyo Group Co., Ltd.) was deodorized under the conditions described in Table 3 to obtain the refined rapeseed oil of each Example and Comparative Example. Next, 800 g of each refined rapeseed oil was poured into a fryer, and each refined rapeseed oil was subjected to a frying process by raising the temperature to 180°C. When the temperature reached 180° C., a portion of the purified rapeseed oil was collected and the following evaluations were performed.

[0094] [Evaluation]

[0095] (α-tocopherol content and trans fatty acid content)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com