Production process of low-oil-fume sunflower seed oil

A sunflower oil and production process technology, applied in the field of sunflower edible oil production process, can solve the problems of trans fatty acid, improper oil cooling, adding antioxidants, etc., to achieve low trans fatty acid content, low oil smoke, The effect of high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

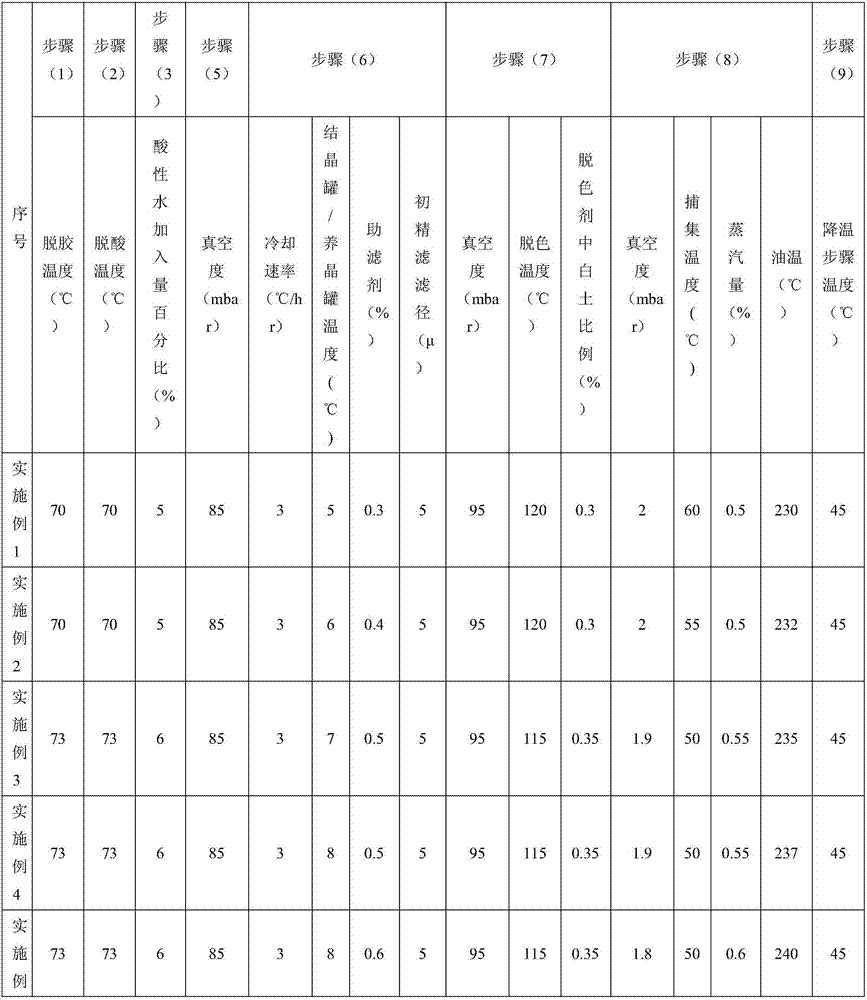

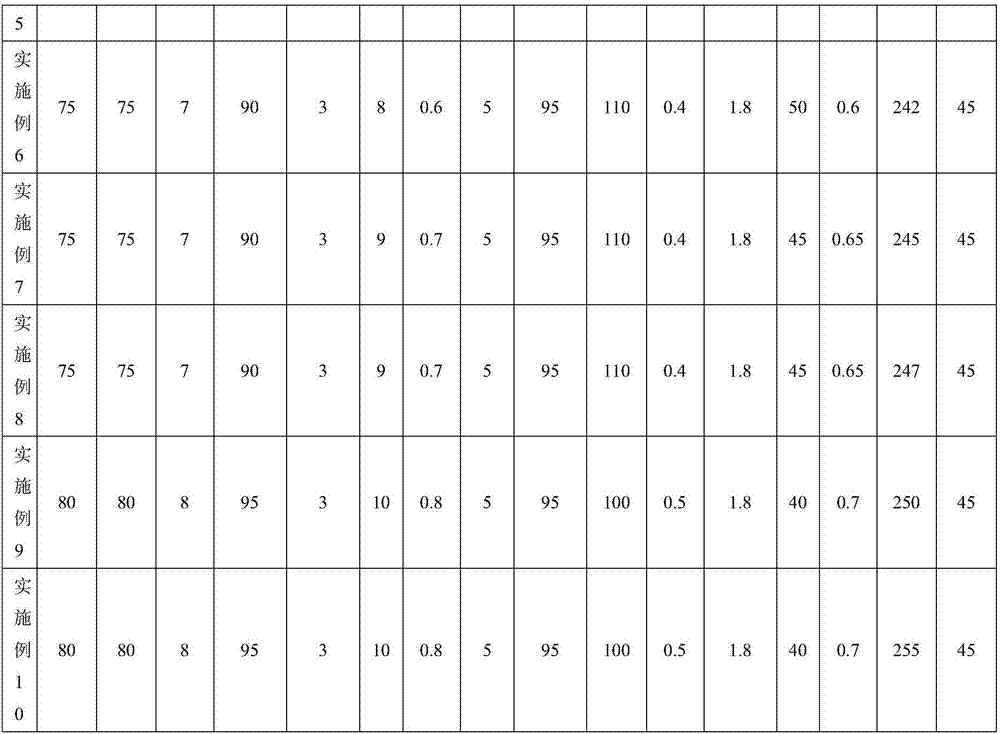

Embodiment 1-10

[0033] The sunflower seed crude oil selected in Examples 1-10 has an FFA value of ≤4%, a water and volatile matter content of ≤0.5%, an insoluble impurity content of ≤0.5%, a phosphorus content of ≤500ppm, and a residual solubility of ≤100ppm.

[0034] The production and processing of the above-mentioned crude sunflower oil into low-smoke sunflower oil comprises the following steps:

[0035] (1) Degumming: the temperature of degumming is controlled at 69°C to 81°C;

[0036] (2) Deacidification: the temperature of deacidification is controlled at 69°C to 81°C;

[0037] (3) Washing: use acidic water for washing, and the amount of acidic water added is 5% to 8% of the oil weight;

[0038] (4) centrifugation: centrifugation after washing;

[0039] (5) Vacuum drying: the vacuum degree of vacuum drying is not more than 100mbar;

[0040] (6) Winterization: pump the dried oil out of the storage tank, adjust the temperature, enter the crystallization tank and crystal growth tank, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com