Method for optimizing blend oil performance by utilizing response surface method and matrix method

A response surface method and oil blending technology, applied in the field of edible oil, can solve the problems of different sources, etc., and achieve the effects of low oil fume, simple operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

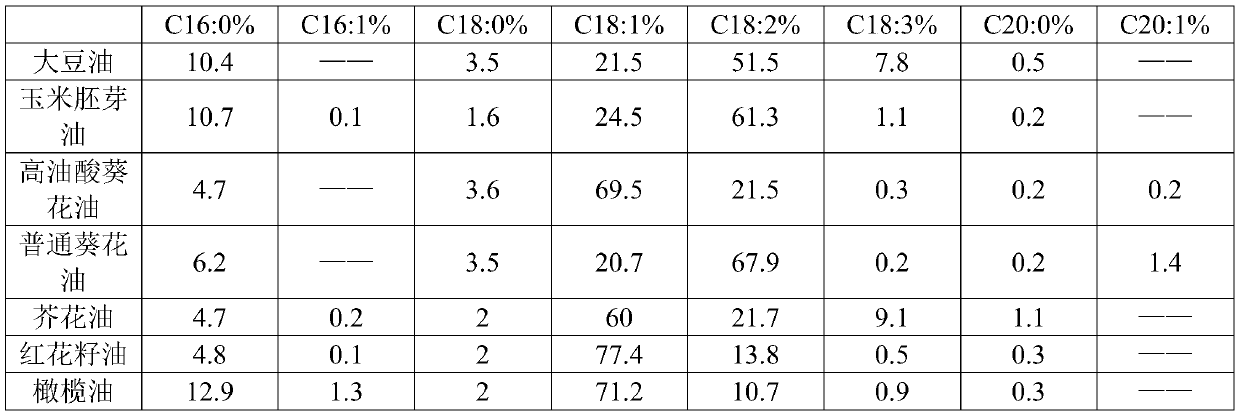

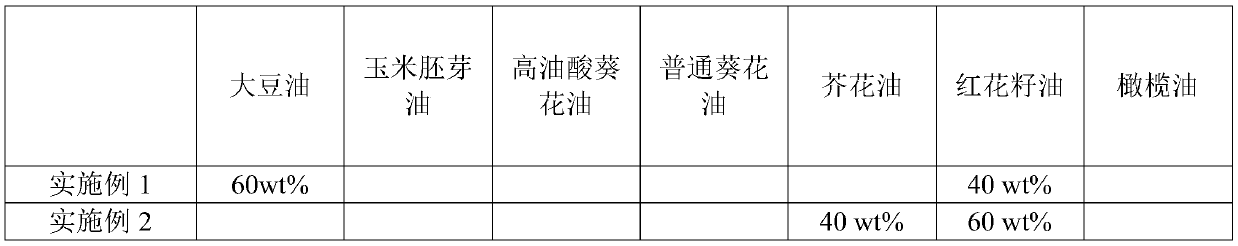

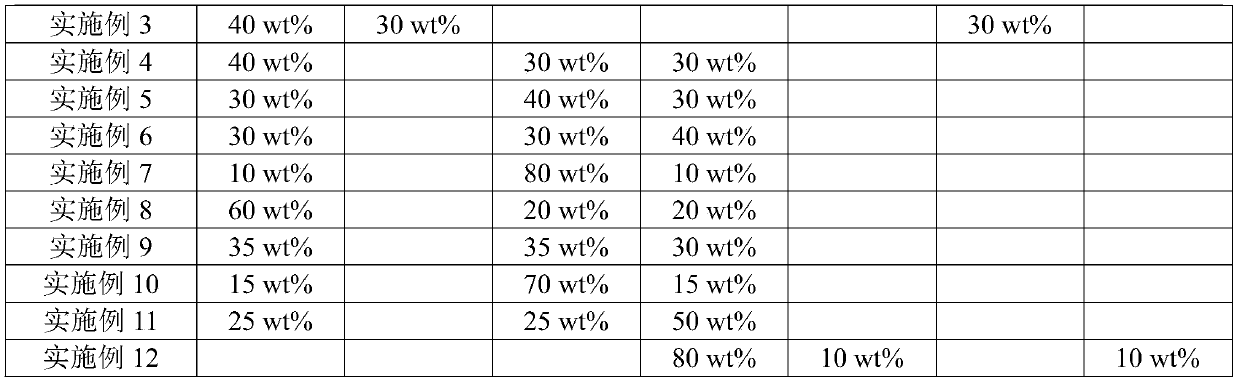

[0019] 1. Select soybean oil, corn germ oil, high oleic sunflower oil, ordinary sunflower oil, canola oil, safflower oil and olive oil to prepare different blended oils as research objects, and test the blended oils respectively The fatty acid composition and oxidation stability index OSI value of the fatty acid are as sample data; Sample data are as shown in table 1;

[0020] 2. According to the relationship between the fatty acid composition and the OSI value of the oxidation stability index, use the response surface method to perform regression analysis on the above sample data, fit the model, analyze and optimize, and establish the regression equation;

[0021] OSI value==13.284+(0.128×F 1 )-(0.255×F 2 )-(0.0401×F 3 )-(0.151×F 4 )-(0.475×F 5 );

[0022] In the formula, F 1 is the mass percentage of saturated fatty acids with 16 carbon atoms in the blended oil; F 2 is the mass percentage of saturated fatty acids with 18 carbon atoms in the blended oil; F 3 is the ma...

Embodiment 2

[0026] 1. Select soybean oil, corn germ oil, high oleic sunflower oil, ordinary sunflower oil, canola oil, safflower oil and olive oil to prepare different blended oils as research objects, and test the blended oils respectively The fatty acid composition and soot amount of the sample data are used as sample data; the sample data are shown in Table 1;

[0027] 2. According to the relationship between the composition of fatty acids and the amount of soot, use the response surface method to perform regression analysis on the above sample data, fit the model, analyze and optimize, and establish a regression equation;

[0028] Soot amount=-0.390+(0.0294×F 1 )+(0.0193×F 2 )+(0.00238×F 3 )+(0.00182×F 4 )+(0.00697×F 5 );

[0029] In the formula, F 1 is the mass percentage of saturated fatty acids with 16 carbon atoms in the blended oil; F 2 is the mass percentage of saturated fatty acids with 18 carbon atoms in the blended oil; F 3 is the mass percentage of unsaturated fatty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com