Deodorizing method for reducing trans-fatty acid content in vegetable oil

A trans fatty acid and vegetable oil technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of deodorization and thermal decolorization that are not as good as trays, long deodorization time, and high operating temperature (260-270℃, etc.) To achieve the effect of benefiting human health, improving the quality of vegetable oil and reducing trans-isomerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

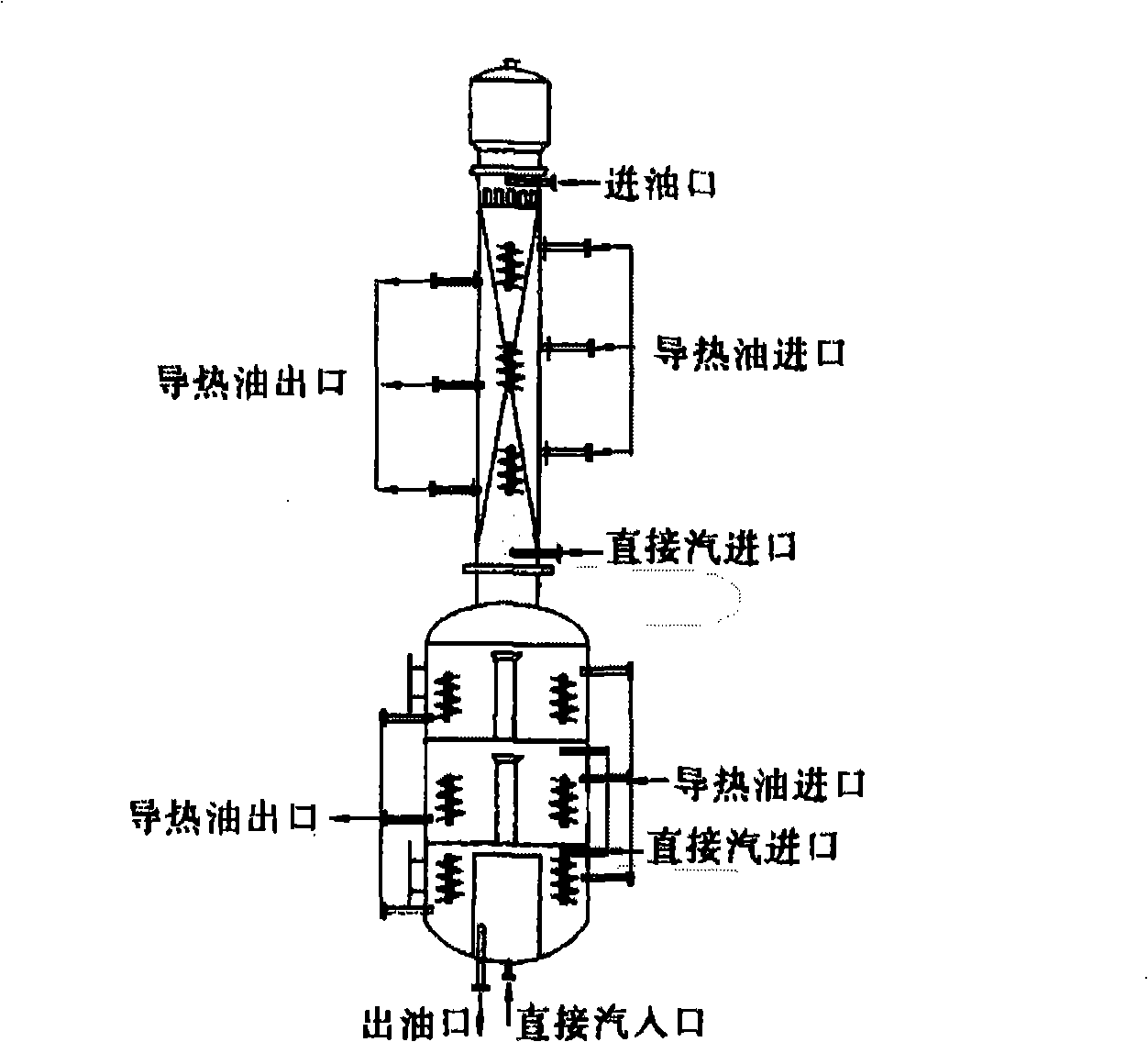

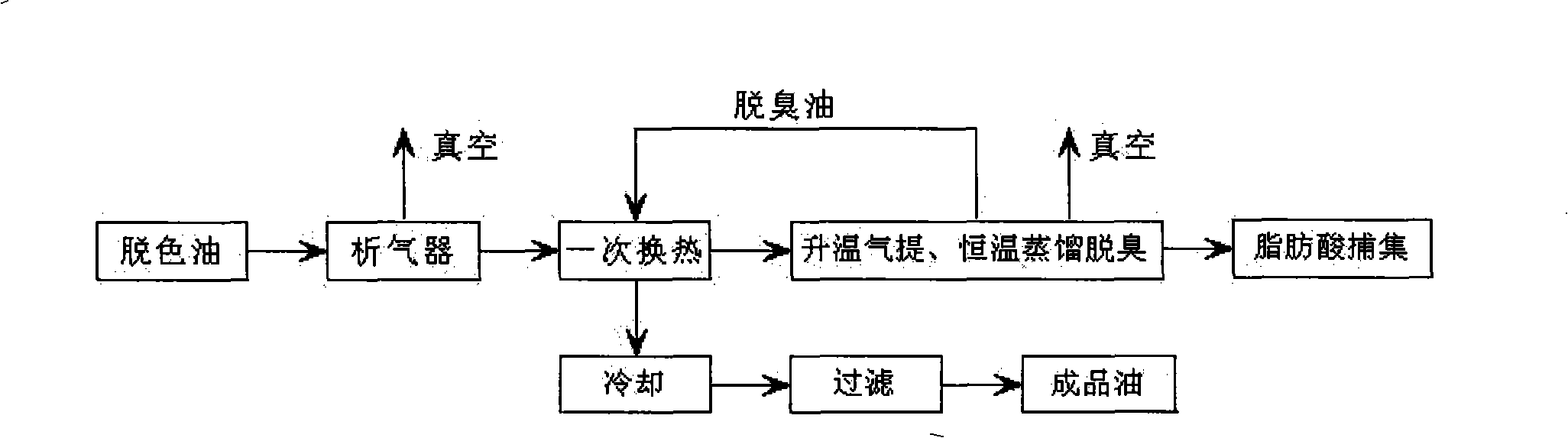

[0040] Under the conditions of 130°C and vacuum degree of 2Torr, the decolorized soybean oil is deoxygenated by the degasser, then the temperature is raised to 185°C through a heat exchange, and the oil flow rate is 18m 3Enter the deodorization tower under the condition of / h, heat up to 240°C step by step in the packed tower section, and use direct steam (0.2% steam volume) to strip for 12 minutes, then enter the plate tower section, use direct steam (0.6% steam volume) constant temperature drum Soak and distill for 45 minutes, cool to 45°C and fine filter to obtain deodorized soybean oil with low trans fatty acid. Determination of trans fatty acid, acid value and color in deodorized oil.

[0041] The content of trans fatty acid in the obtained final deodorized soybean oil was 0.89%, the content of free fatty acid was 0.032%, and the color was Y9R0.8.

Embodiment 2

[0043] The decolorized rapeseed oil is at 130°C and the vacuum degree is 2 Torr. After being deoxygenated by the degasser, the temperature is raised to 190°C through a heat exchange. 3 Enter the deodorization tower under the condition of / h, heat up to 245°C step by step in the packed tower section, and use direct steam (0.2% steam volume) to strip for 8 minutes, then enter the plate tower section, use direct steam (0.6% steam volume) constant temperature drum Soak and distill for 40 minutes, cool to 45°C, and fine filter to obtain deodorized rapeseed oil with low trans fatty acids. Measure the trans fatty acids, acid value and color in the deodorized oil.

[0044] The content of trans fatty acid in the obtained final deodorized rapeseed oil was 1.02%, the content of free fatty acid was 0.030%, and the color was Y6R0.6.

Embodiment 3

[0046] Under the conditions of 130°C and vacuum degree of 2 Torr, the decolorized corn oil is deoxygenated by the degasser, then the temperature is raised to 190°C through a heat exchange, and then the temperature is raised to 260°C through a second heat exchange. 3 Enter the deodorization tower under the condition of 1 / h, strip in the packed tower section for 10 minutes, then enter the plate tower section, use direct steam (0.8% steam volume) bubbling distillation for 50 minutes, cool to 45°C and fine filter to obtain low-trans fatty acid Deodorized corn oil, determination of trans fatty acid, acid value and color in deodorized oil.

[0047] The content of trans fatty acid in the obtained final deodorized corn oil was 2.17%, the content of free fatty acid was 0.026%, and the color was Y5R0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com