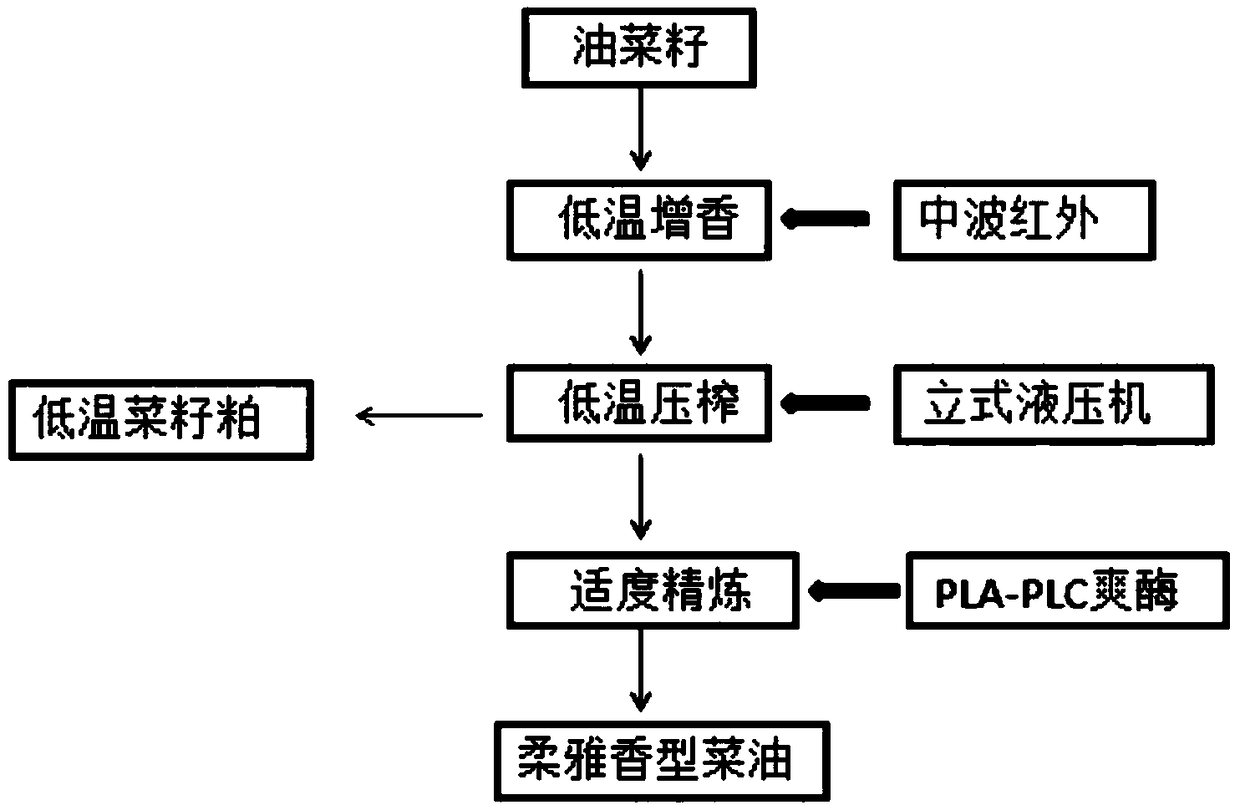

Method for preparing high-quality rapeseed oil through integration of low-temperature technologies

A kind of rapeseed oil, high-quality technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of not being affected by time and space, taste, appearance and nutritional components, low equipment requirements, etc. , to achieve the effect of ensuring nutritional quality and value, improving development and utilization value, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

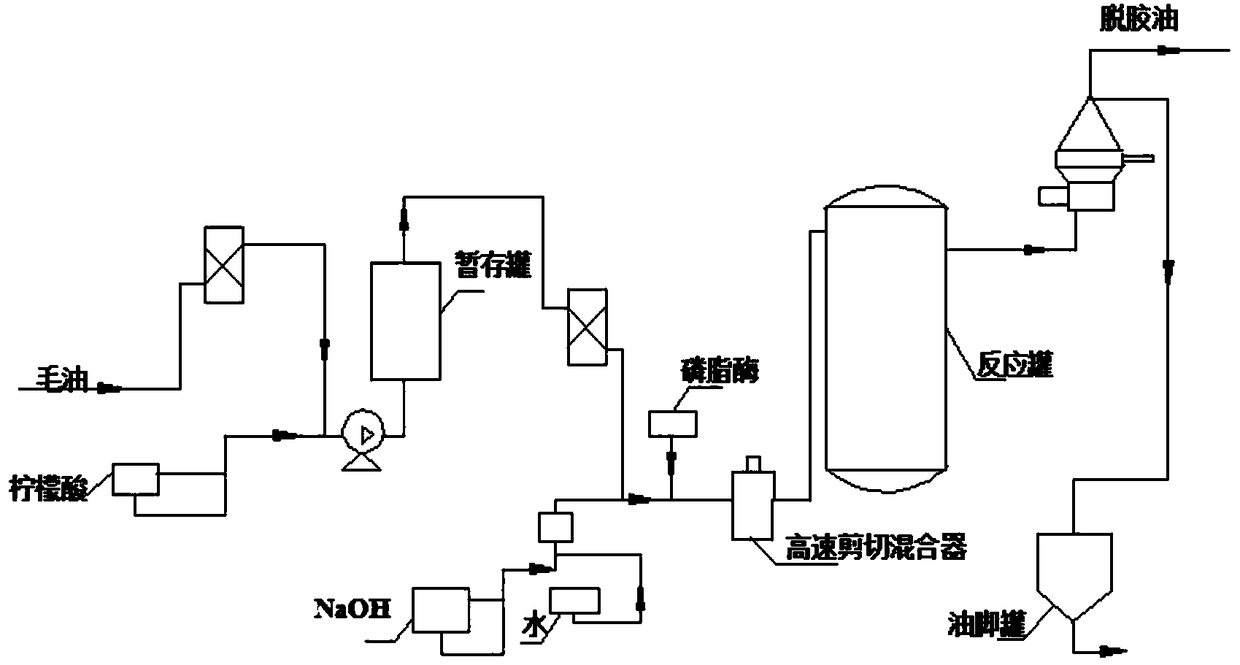

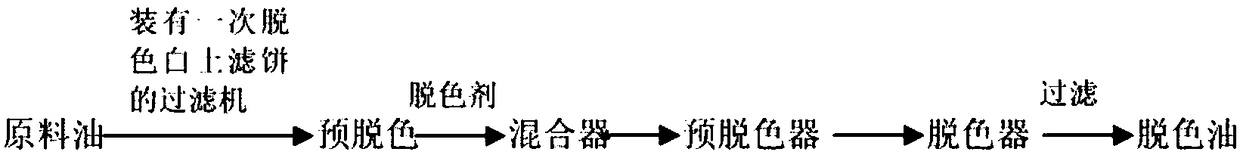

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 rapeseed oil

[0032] (1) Take 25kg of rapeseed, put the screened rapeseed into the infrared heating machine for processing by vacuum suction (heating at 130°C for 40min, processing distance 20cm, material thickness 5cm, infrared wavelength about 2.5μm)

[0033] (2) Utilize a three-column hydraulic oil press to extract oil from the rapeseed after step (1) infrared treatment, and gradually increase the pressure to prepare rapeseed oil:

[0034] The first stage: 10 ~ 12bar treatment for 30mins;

[0035] The second stage: 25~28bar treatment for 30mins;

[0036] The third stage: 45 ~ 48bar treatment for 30 minutes;

[0037] The fourth stage: 95~98bar treatment for 30mins;

[0038] The fifth stage: 290~295bar treatment for 30mins;

[0039] The sixth stage: 570~585bar treatment for 30mins.

[0040] Rapeseed crude oil is obtained by centrifugal separation at room temperature at 4500 r / min in a centrifuge.

[0041] (3) Add 1% PLA-PLC and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com