Mini popcorn and making method thereof

A popcorn and miniature technology, applied in the field of food processing, can solve the problems of soft taste, poor brittleness, and large popcorn particles, and achieve the effects of sweet taste, good brittleness, good popping rate and puffing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

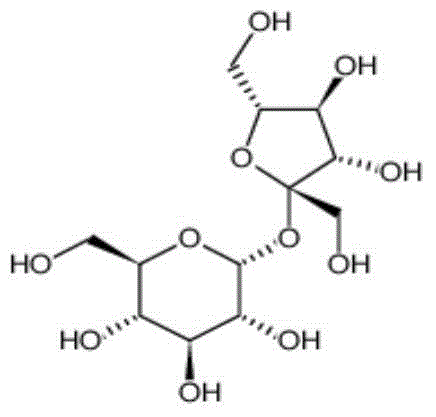

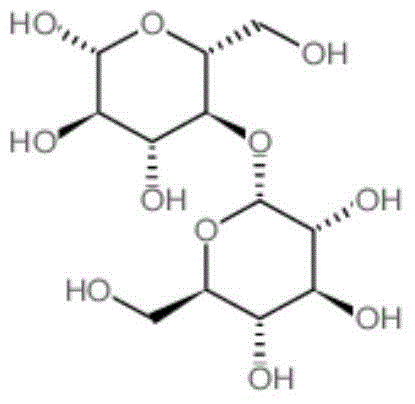

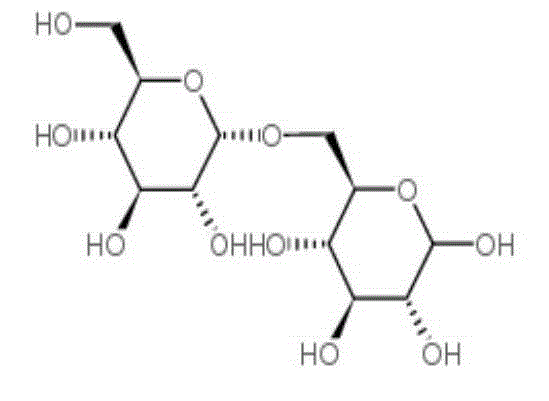

Image

Examples

Embodiment 1

[0041] Raw materials for mini popcorn: 10kg of corn, 7kg of palm oil, 11kg of white sugar, 6kg of maltose, 5kg of low-sodium salt, and 0.055kg of β-carotene.

[0042] The preparation method of miniature popcorn comprises the following steps:

[0043] (1) Soak the corn kernels in water so that the moisture content in the corn kernels is 24wt%;

[0044] (2) Add palm oil into an open pot, heat to 180°C, then add the soaked corn kernels in step (1), stir at 300 rpm for 30 seconds, then add white sugar, maltose, low sodium salt, β- Carotene, the material temperature is controlled at 190° C., and the stirring is continued in an open pot for 3 minutes, and the corn kernels are popped to obtain the miniature popcorn.

Embodiment 2

[0046] Micro-popcorn raw materials: corn 10kg, palm oil 7kg, white sugar 11kg, maltose 2kg, isomaltose 2kg, isomaltose 2kg, low sodium salt 5kg, β-carotene 0.055kg.

[0047] The preparation method of miniature popcorn comprises the following steps:

[0048] (1) Soak the corn kernels in water so that the moisture content in the corn kernels is 24wt%;

[0049](2) Add palm oil into an open pot, heat to 180°C, then add the soaked corn kernels in step (1), stir at 300 rpm for 30 seconds, then add white sugar, maltose, isomaltose, and isomalt Sugar, low-sodium salt, β-carotene, the material temperature is controlled at 190° C., and the stirring is continued in an open pot for 3 minutes, and the corn kernels are popped to obtain the miniature popcorn of Example 2.

Embodiment 3

[0051] Raw materials for mini popcorn: 10kg of corn, 7kg of palm oil, 11kg of white sugar, 3kg of maltose, 3kg of isomaltose, 5kg of low-sodium salt, and 0.055kg of β-carotene.

[0052] The preparation method of miniature popcorn comprises the following steps:

[0053] (1) Soak the corn kernels in water so that the moisture content in the corn kernels is 24wt%;

[0054] (2) Add palm oil into the open pot, heat to 180°C, then add the soaked corn grains in step (1), stir at 300 rpm for 30 seconds, then add white sugar, maltose, isomaltose, and low-sodium salt , β-carotene, control the material temperature to be 190° C., continue to stir in an open pot for 3 minutes, pop the corn kernels, and obtain the miniature popcorn of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com