Refining method of low trans-fatty acid compound oil

A low-trans fatty acid and compound oil technology, applied in the field of daily life, can solve the problems of insufficient supply capacity and high price of compound nutritional oil raw materials, and achieve the effect of reducing production costs and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

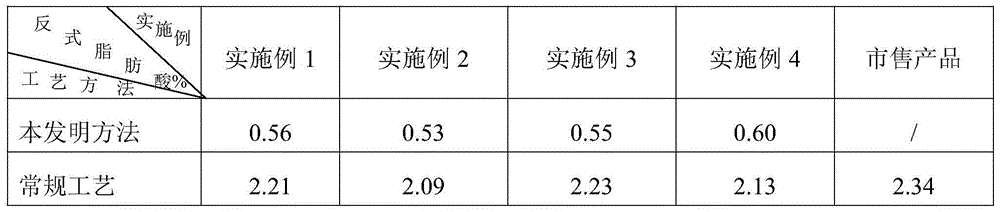

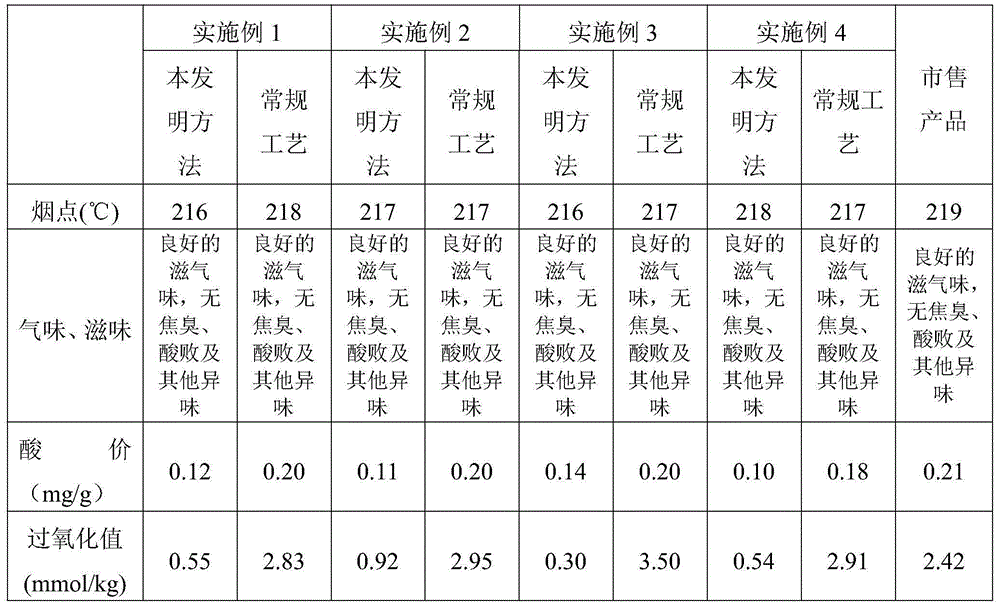

Examples

Embodiment 1

[0018] Add 20 tons of soybean oil, 5 tons of corn oil, and 60 tons of rapeseed oil into the raw material batching tank, fully stir and mix, and quantitatively enter the refining process for conventional degumming, deacidification, and decolorization treatments.

[0019] Degumming: Use medium temperature or high temperature hydration degumming method. First take a sample to test the content of phospholipids in the oil so as to determine the amount of water added. The oil is heated to 80°C, demineralized water with 3.5 times the amount of phospholipids is added, mixed thoroughly and centrifuged after a delay.

[0020] Deacidification: The acid value of the oil is determined by sampling to determine the amount of alkali to be added. Heat the oil to 80°C, add 20 Baumé lye according to the acid value, mix thoroughly and centrifuge after a delay. Then add hot water at the same temperature with 10% oil weight, mix well, wash and centrifuge. The deacidified oil is heated to 95°C fo...

Embodiment 2

[0026] Add 25 tons of soybean oil, 7 tons of corn oil, and 65 tons of rapeseed oil into the raw material batching tank, fully stir and mix, and quantitatively enter the refining process for conventional degumming, deacidification, and decolorization treatments.

[0027] Degumming: Use medium temperature or high temperature hydration degumming method. First take a sample to test the content of phospholipids in the oil so as to determine the amount of water added. The oil is heated to 80°C, demineralized water with 3.5 times the amount of phospholipids is added, mixed thoroughly and centrifuged after a delay.

[0028] Deacidification: The acid value of the oil is determined by sampling to determine the amount of alkali to be added. Heat the oil to 85°C, add 20 Baumé lye according to the acid value, mix thoroughly and centrifuge after a delay. Then add hot water at the same temperature with 20% oil weight, mix well, wash and centrifuge. The deacidified oil is heated to 95°C fo...

Embodiment 3

[0034] Add 30 tons of soybean oil, 8 tons of corn oil, and 70 tons of rapeseed oil into the raw material batching tank, fully stir and mix, and quantitatively enter the refining process for conventional degumming, deacidification, and decolorization treatments.

[0035] Degumming: Use medium temperature or high temperature hydration degumming method. First take a sample to test the content of phospholipids in the oil so as to determine the amount of water added. The oil is heated to 80°C, demineralized water with 3.5 times the amount of phospholipids is added, mixed thoroughly and centrifuged after a delay.

[0036] Deacidification: The acid value of the oil is determined by sampling to determine the amount of alkali to be added. Heat the oil to 90°C, add 20 Baumé lye according to the acid value, mix thoroughly and centrifuge after a delay. Then add hot water at the same temperature with 30% oil weight, mix well, wash and centrifuge. The deacidified oil is heated to 95°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com