Refined plant oil and preparation method thereof

A technology for refining vegetable oils and plants, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of high trans fatty acid content, increased vitamin E loss, incomplete degumming and alkali refining, etc., and achieve low trans fatty acid content. , The loss rate of vitamin E is low, and the effect of avoiding high deodorization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

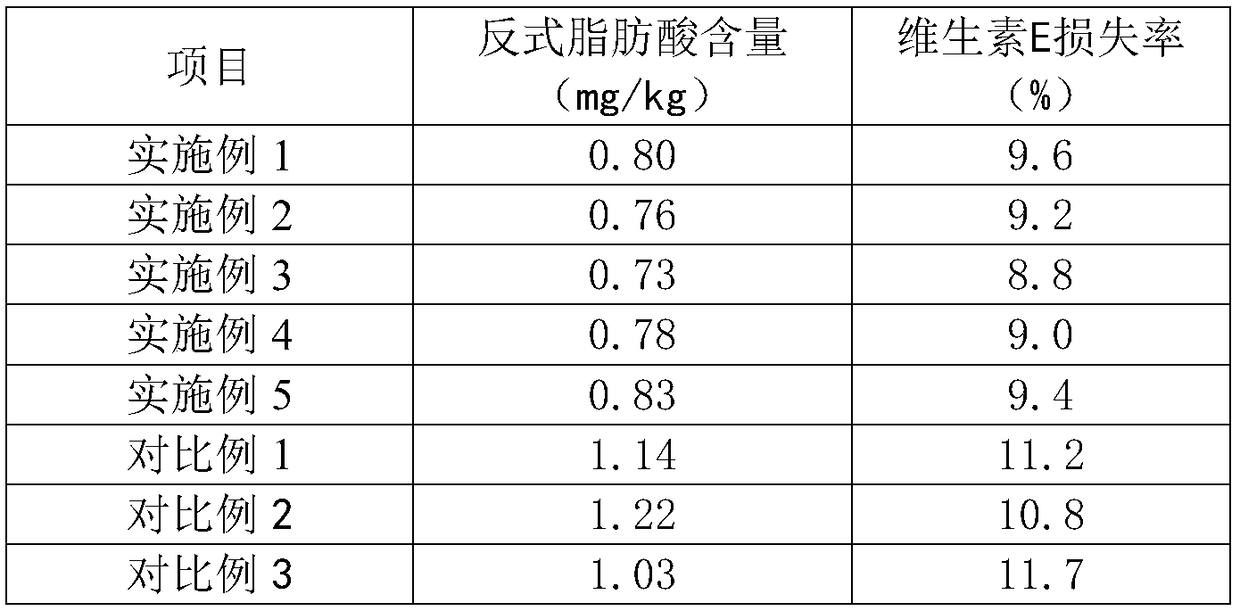

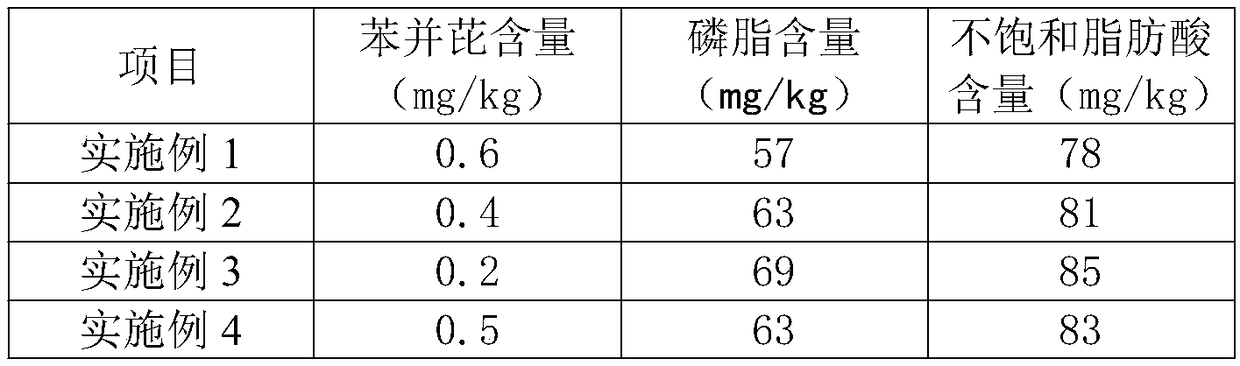

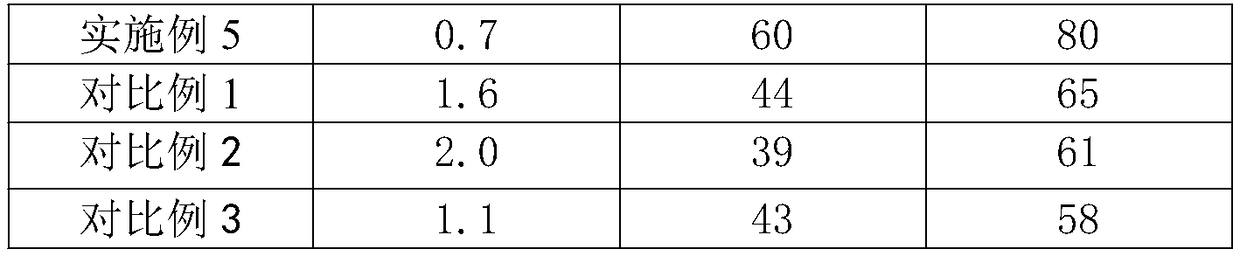

Examples

Embodiment 1

[0032] The preparation method of the refined vegetable oil of the present embodiment may further comprise the steps:

[0033] (1) Impurity removal: insert the ultrasonic probe into the vegetable crude oil, ultrasonically treat it for 20 minutes, and then put the ultrasonically treated vegetable crude oil into the foam ceramic filter plate for filtration;

[0034] (2) Degumming:

[0035] 2A, a degumming neutralization reaction: add the vegetable crude oil after the impurity removal in step (1) into the neutralization reactor, first heat the crude oil to 45°C, and then add 0.1% of the crude oil weight and a concentration of 75% Phosphoric acid, after fully mixing, after staying for 10 minutes, add the prepared edible alkali solution, stir for 30 minutes, let it stand for 3 hours, open the bottom valve, and discharge the bottom sediment;

[0036] 2B. Secondary degumming and neutralization reaction: put the crude vegetable oil treated in 2A into another neutralization reaction ke...

Embodiment 2

[0050] The preparation method of the refined vegetable oil of the present embodiment may further comprise the steps:

[0051] (1) Impurity removal: Insert the ultrasonic probe into the vegetable crude oil, ultrasonically treat it for 30 minutes, and then put the ultrasonically treated vegetable crude oil into the foam ceramic filter plate for filtration;

[0052] (2) Degumming:

[0053] 2A, a degumming neutralization reaction: add the vegetable crude oil after the impurity removal in step (1) into the neutralization reactor, first heat the crude oil to 55°C, and then add 0.5% of the crude oil weight and a concentration of 75% Phosphoric acid, after fully mixing, after staying for 20 minutes, add the prepared edible alkali solution, stir for 50 minutes, let it stand for 5 hours, open the bottom valve, and discharge the bottom sediment;

[0054] 2B. Secondary degumming and neutralization reaction: Put the crude vegetable oil treated in 2A into another neutralization reaction ke...

Embodiment 3

[0068] The preparation method of the refined vegetable oil of the present embodiment may further comprise the steps:

[0069] (1) Impurity removal: Insert the ultrasonic probe into the vegetable crude oil, ultrasonically treat it for 25 minutes, and then put the ultrasonically treated vegetable crude oil into the foam ceramic filter plate for filtration;

[0070] (2) Degumming:

[0071] 2A, a degumming neutralization reaction: add the vegetable crude oil after the impurity removal in step (1) into the neutralization reactor, first heat the crude oil to 50°C, and then add 0.3% of the crude oil weight and a concentration of 75% Phosphoric acid, after fully mixing, after staying for 15 minutes, add the prepared edible alkali solution, stir for 40 minutes, let it stand for 4 hours, open the bottom valve, and discharge the bottom sediment;

[0072] 2B. Secondary degumming and neutralization reaction: put the crude vegetable oil treated in 2A into another neutralization reactor thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com