Industrialized production method of high-quality low-cost chocolate

A production method and chocolate technology, applied in cocoa, food science, application and other directions, can solve problems such as the influence of chocolate taste, and achieve the effects of reducing heat, reducing production costs, and maintaining quality and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

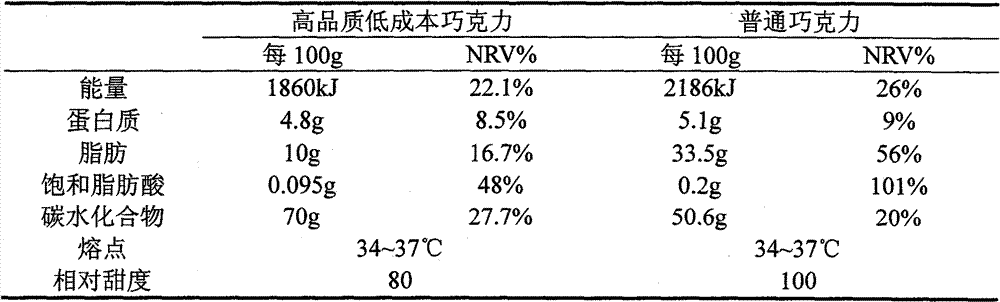

Embodiment 1

[0027] 15kg of whole milk powder, 70kg of sucrose, and 3g of sweetness inhibitor 2-(4-methoxyphenoxy)sodium propionate were added in a mixer, at a temperature of 35°C, at a speed of 30r / min and mixed for 10min, After mixing evenly, add 10 kg of melted cocoa slurry containing 55% cocoa butter and 3 g of triterpene glycoside natural sweetness inhibitor, and mix for 10 min at a temperature of 35° C. and a speed of 30 r / min. Under the condition of 40MPa, the homogeneously mixed material is homogenized under high pressure once to obtain material particles of 10 μm. Then, after the material was refined at 50°C for 10 hours at 80r / min, 4kg of cocoa butter, 0.99kg of lecithin and 4g of 2-(4-methoxyphenoxy)sodium propionate were added, and at 40r / min After mixing evenly at low temperature, refine at 45°C for 36h. After the refining is completed, the material enters the temperature adjustment stage. After cooling down to 20°C at a rate of 10°C / min, the temperature is raised to 33°C. A...

Embodiment 2

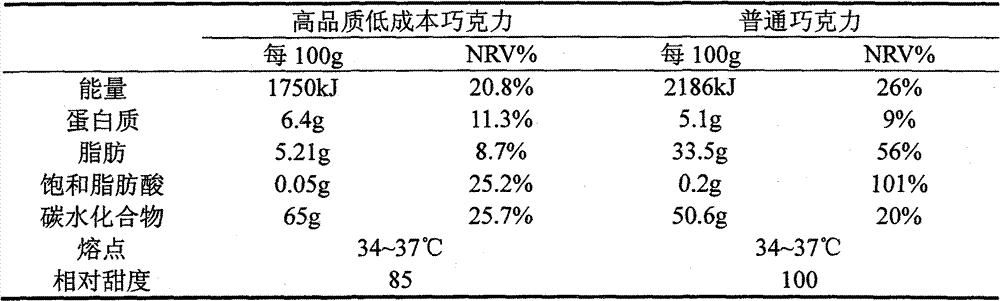

[0032] 20kg of whole milk powder, 65kg of sucrose, and 3g of triterpene glycoside natural sweetness inhibitor were added in a mixer, at a temperature of 35°C and a speed of 40r / min, and mixed for 10min. After mixing evenly, 10kg of melted 55% The cocoa slurry of cocoa butter and 3g of triterpene glycoside natural sweetness inhibitor were mixed for 10 minutes at a temperature of 35° C. and a rotation speed of 40 r / min. Under the condition of 50MPa, the homogeneously mixed material is homogenized under high pressure once to obtain material particles of 10 μm. Then, the material was refined at 50°C for 10 hours at 100r / min, then 4kg of cocoa butter, 0.99kg of lecithin and 4g of triterpene glycoside natural sweetness inhibitor were added, and after mixing evenly at 60r / min, the Refining for 36 hours at 45°C. After the refining is completed, the material enters the temperature adjustment stage. After cooling down to 15°C at a rate of 8°C / min, the temperature is raised to 33°C at a...

Embodiment 3

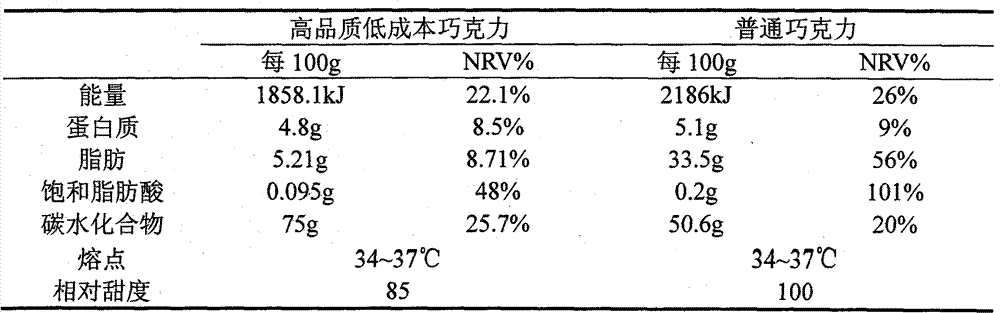

[0037] 15kg of whole milk powder, 75kg of sucrose, and 3g of forest spoon gymnemic acid were added to the mixer, and mixed for 10min at a temperature of 35°C and at a speed of 30r / min. After mixing evenly, 9kg of melted cocoa containing 55% cocoa butter was added The slurry and 3 g of gymnemic acid were mixed for 10 min at a temperature of 35° C. and a rotational speed of 30 r / min. Under the condition of 40MPa, the homogeneously mixed material is homogenized under high pressure once to obtain material particles of 10 μm. Then, the material was refined at 50°C for 10 hours at 80r / min, then 0.99kg of lecithin and 4g of Gymnemic acid were added, mixed evenly at 40r / min, and refined at 45°C for 36h. After the refining is completed, the material enters the temperature adjustment stage. After cooling down to 15°C at a rate of 5°C / min, the temperature is raised to 33°C. After the temperature adjustment is completed, the material is poured into a mold. After the mold is poured, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com