Method for producing bean products

A soybean product and dry method technology, which is applied in the field of whole soybean dry method to produce soybean products, can solve the problems of reducing shelf life and increasing production cost, and achieves the effects of good storage, improved utilization rate and low water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

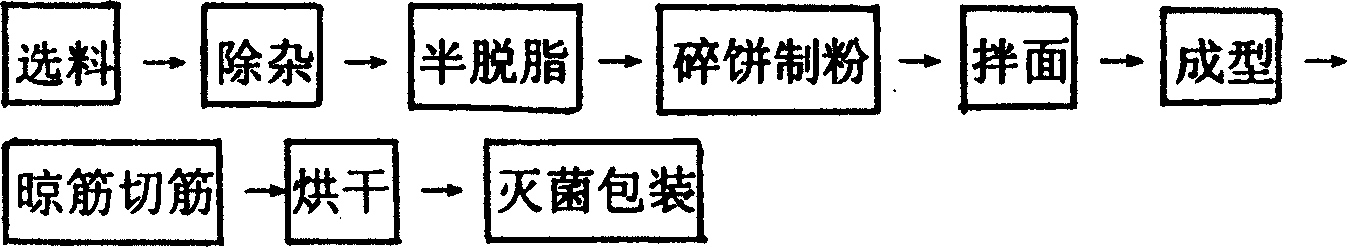

[0046] The present embodiment provides the method that whole bean dry method produces soybean gluten, and its specific technological process is as follows figure 1 As shown, the specific process is as follows:

[0047] 1. Material selection

[0048] Choose high-quality soybeans as raw materials, preferably high-quality soybeans from Heilongjiang Hailun Agricultural Greening. The bean gluten made from this kind of soybean has good color and high nutritional value.

[0049] 2. Remove impurities

[0050] Pick out bad beans, variegated beans, mildewed beans and pods, soil blocks, stones and other sundries, and then clean or wipe the outside of the soybeans.

[0051] 3. Semi-skimmed

[0052] Soybeans are pressed and degreased with an oil press. Soybeans generally contain 18.4-20% fat, and about 50% of the fat is reduced by semi-skimming. The semi-skimmed bean cake is tile-like, yellowish-white, with no oil stain on the surface, and the oil content remains about 7-9%.

[0053]...

Embodiment 2

[0074] The present embodiment provides the technology of making spicy instant bean product, wherein, the technology before extrusion molding is the same

[0075] Example 1, thereafter,

[0076] a. Place the extruded wet bean product in the natural environment to dry, fix the shape, and the drying time is 25 minutes;

[0077] b. Cut the fixed and formed soybean products into sections according to the requirements of finished products;

[0078] c. Add powdered seasoning, mix well,

[0079] d. Pour hot vegetable oil into the soy products and mix well. The temperature of the vegetable oil is 250-300°C.

[0080] The weight ratio with bean products is 100:1.5-2.

[0081] e. Put the bean product mixed with seasoning into a packaging bag or a packaging bottle, vacuumize and seal the packaging.

[0082] To make spicy bean products, the above-mentioned condiments can include salt, sugar, chili powder, soy sauce, etc., and the consumption of various condiments is formulated according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com