Hydrogenation catalyst with low trans-acid grease and preparation method thereof

A low-trans-acid oil and hydrogenation catalyst technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve problems such as inability to apply industrial production, Achieve the effects of improving catalyst activity, reducing trans fatty acid content, and increasing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

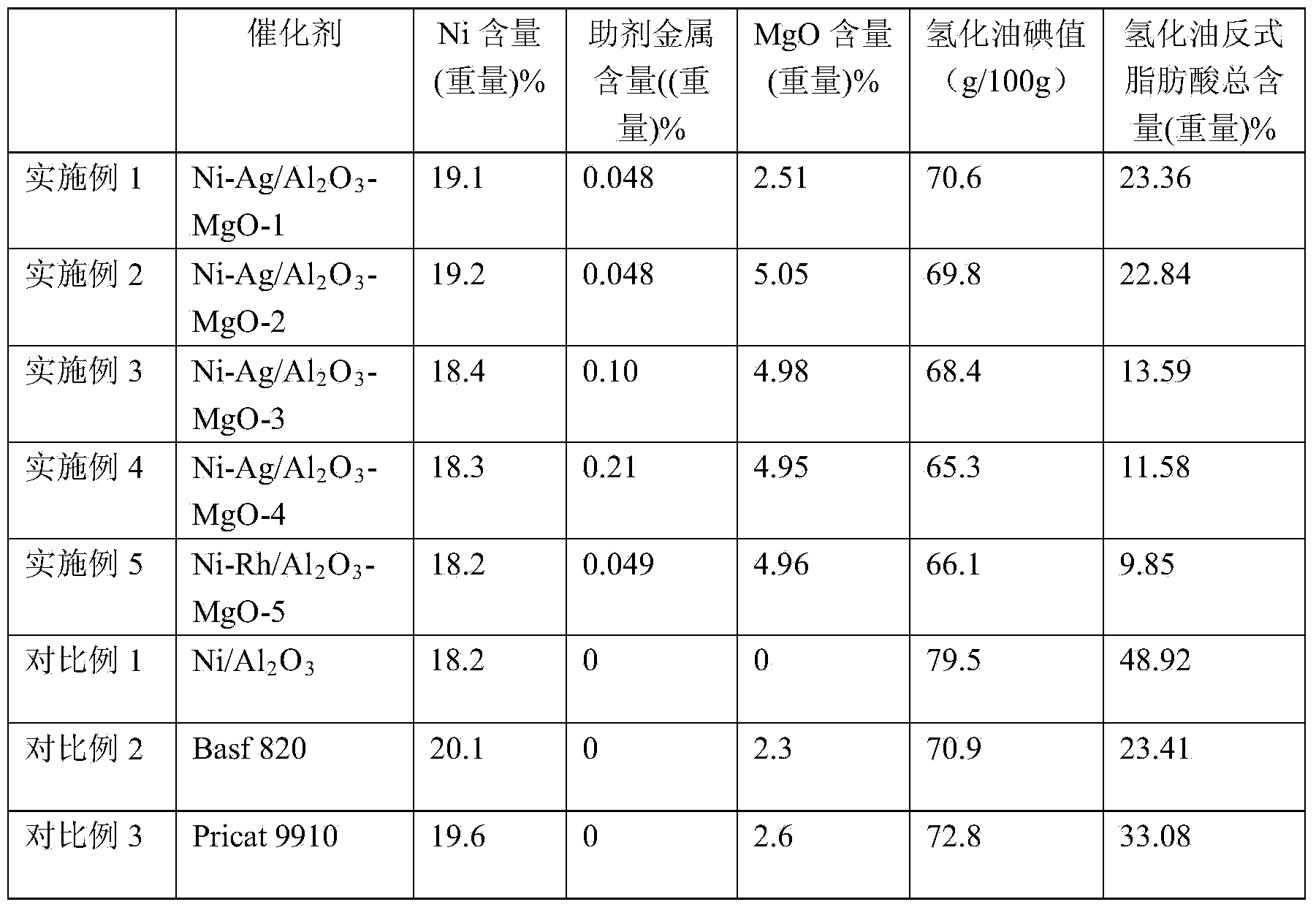

Examples

Embodiment 1

[0018] Take 5 g of magnesium oxide powder and add it to 200 ml of distilled water, stir evenly, add it into the neutralization kettle as the reaction bottom liquid, and heat it up to 85°C. Add 150mL of aluminum sulfate solution with a concentration of 1.00mol / L and 220mL of sodium metaaluminate solution with a concentration of 4.00mol / L into the neutralization reactor in parallel, and keep the reaction temperature at 85°C under mechanical stirring for the entire reaction system . After 1 hour, the neutralization reaction was completed, and the reaction liquid was aged, and the aging time was controlled for 60 minutes. After aging, the slurry was filtered, the filter cake was washed with deionized water and absolute ethanol, and dried at 110° C. for 4 hours to obtain an alumina-magnesia composite carrier.

[0019] At room temperature, soak the dried carrier in an aqueous solution containing 0.16 g of silver nitrate, stir and impregnate for 4 hours, then dry and roast. Soak th...

Embodiment 2

[0023] In Example 1, the magnesium oxide powder addition was changed to 10g, the aluminum sulfate solution was changed to 135mL, and the sodium metaaluminate solution was changed to 200mL, and others were the same as in Example 1. Table 1 shows the reaction results of the catalyst's soybean oil hydrogenation performance evaluation.

Embodiment 3

[0025] The silver nitrate add-on in embodiment 1 is increased to 0.32g, and other is with embodiment 1. Table 1 shows the reaction results of the catalyst's soybean oil hydrogenation performance evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com