Method for refining hot-dipping coating material by employing laser heat treatment

A technology of laser heat treatment and layer material, which is applied in the field of heat treatment of material surface and heat treatment of material surface coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

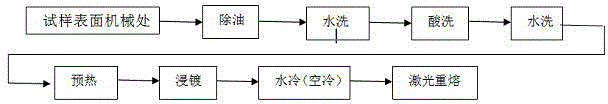

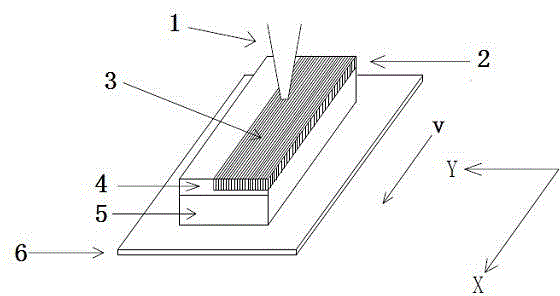

[0025] In this example, see figure 1 and figure 2 , a method for laser remelting to refine hot-dip coating alloy grains, the specific steps are as follows: Mechanical treatment on the surface of the device-degreasing-washing-pickling-washing-preheating-dip-plating-water cooling. Fix the hot-dipped plate on the X-Y moving plate 6, and the laser beam 1 with the set power is emitted from the laser and hits the surface of the substrate 5 of the device to form a circular spot on the surface. Due to the thermal action of the laser, a molten pool 3 is formed on the surface of the substrate 5 . At the same time, the X-Y moving plate 6 drives the substrate 5 to move in the X and Y directions, so that the laser forms a melting channel on the substrate along the scanning direction v, and the overlapping part between the previous melting channel and the subsequent melting channel is the overlapping area. , and finally form a new layer of alloy layer 2 on the surface of the substrate, s...

Embodiment 2

[0031] This embodiment is basically the same as Embodiment 1, especially in that:

[0032] In the present embodiment, hot-dip plating experiment is as follows:

[0033] The surface of the sample is mechanically treated, degreasing, washing with water, pickling, washing with water, preheating, immersion plating, and water cooling. The specific steps are:

[0034] (1) This step is the same as in Example 1; (2) This step is the same as in Example 1; (3) This step is the same as in Example 1; (4) The weighed aluminum-zinc-silicon ingot (the composition is 55% Al-43.3%Zn-1.6%Si) was placed in a crucible, and the crucible was placed in a self-made dipping furnace, and 5L / min of 10%H 2 +N 2 Mix the gas to ensure a slight positive pressure in the furnace body, heat the crucible to 600°C, and perform the hot-dip plating experiment after the alloy ingot is completely melted; (5) This step is the same as that of Example 1.

[0035] Then the GL hot-dip coating is remelted by laser. Th...

Embodiment 3

[0037] This embodiment is basically the same as the previous embodiment, and the special features are:

[0038] Hot-dip plating experiments are as follows:

[0039] The surface of the sample is mechanically treated, degreasing, washing with water, pickling, washing with water, preheating, immersion plating, and water cooling. The specific steps are:

[0040] (1) This step is the same as in Example 1; (2) This step is the same as in Example 1; (3) This step is the same as in Example 1; (4) The weighed aluminum-zinc ingot (composition is 5%Al , 0.03% RE, and the balance is Zn) placed in the crucible, and put the crucible into a self-made dipping furnace, and passed 5L / min of 10%H 2 +N 2 Mix the gas to ensure the slight positive pressure of the furnace body, heat the crucible to 430°C, and perform the hot-dip plating experiment after the alloy ingot is completely melted; (5) This step is the same as that of Example 1.

[0041] Then the Galfan hot-dip coating is remelted by la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com