Three-dimensional scanning forming device and method based on laser forming

A three-dimensional, laser forming technology, applied in the direction of manufacturing auxiliary devices, solid material additive processing, additive manufacturing, etc., can solve the problems of restricting technology promotion and application, low scanning efficiency, etc., to improve printing efficiency, improve printing accuracy, The effect of avoiding interlayer errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

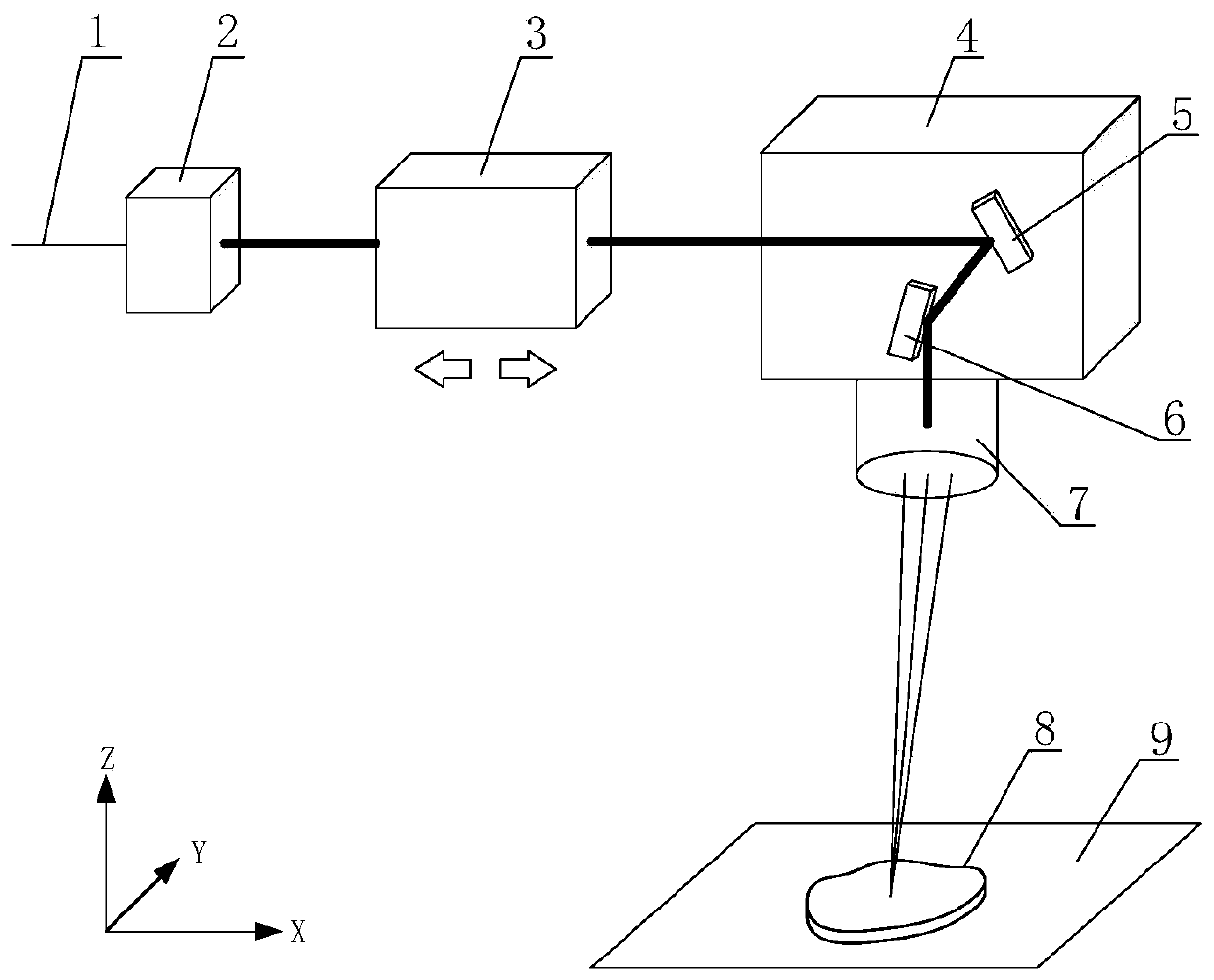

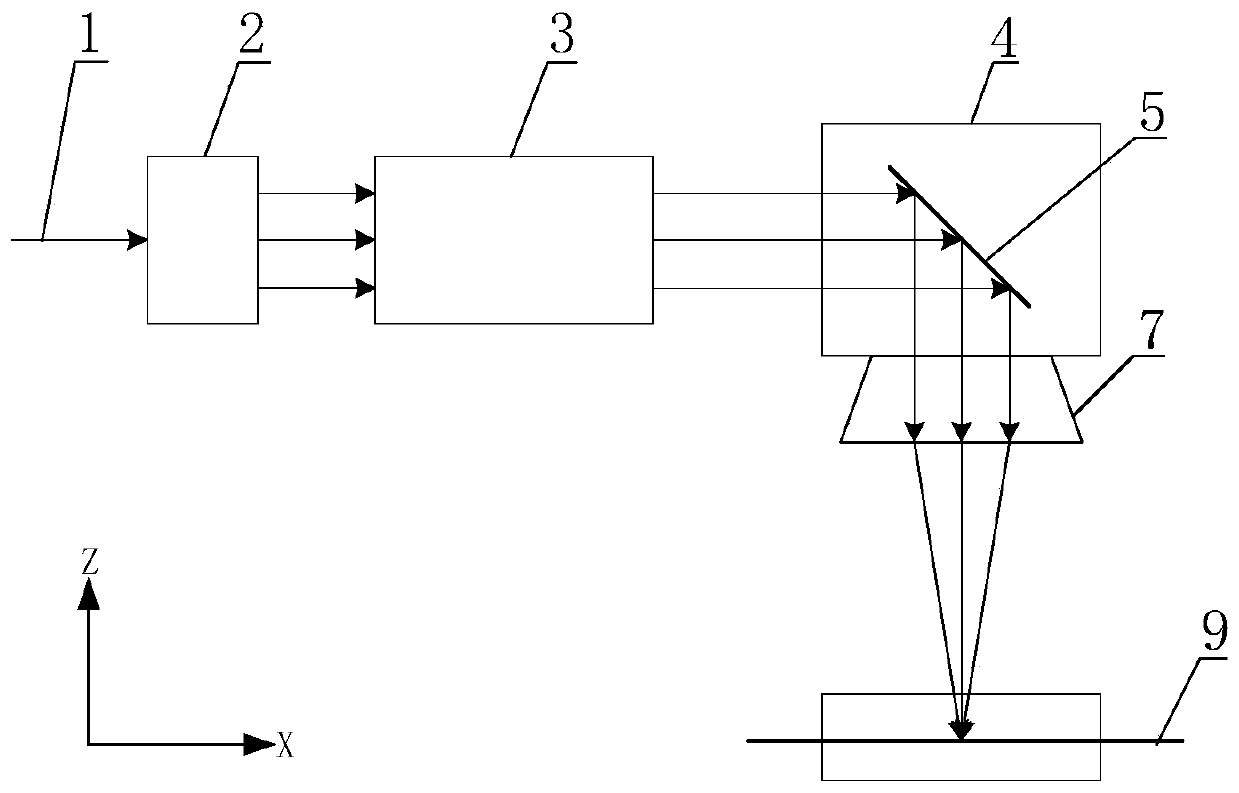

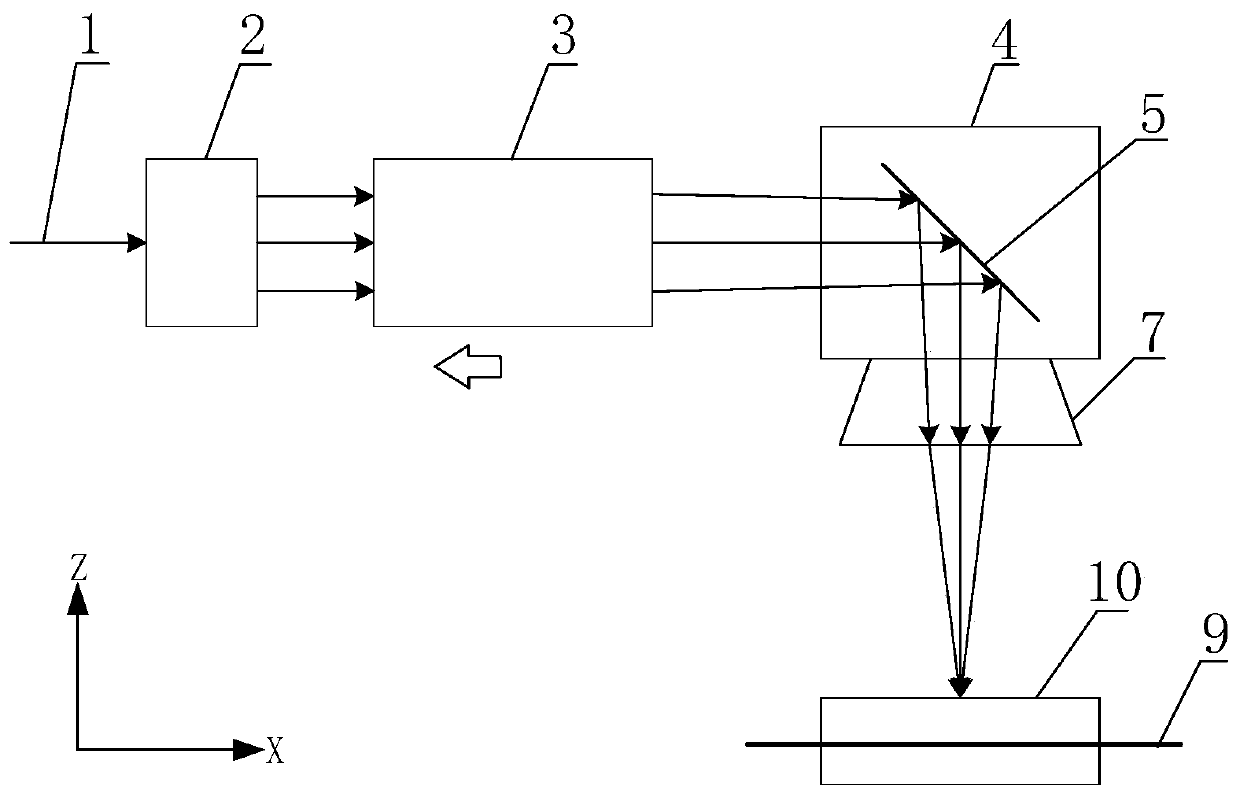

[0032] Such as figure 1 As shown, a three-dimensional scanning forming device based on laser forming includes a collimating beam expander 2, an adjusting mirror 3, a vibrating mirror 4 and a field mirror 7; the collimating beam expanding mirror 2, the adjusting mirror 3, and the vibrating mirror 4 are in On a straight line, the positions of the collimator beam expander 2 and the galvanometer 4 are fixed, the adjustment mirror 3 can move in a straight line between the collimator beam expander 2 and the galvanometer 4, and the field lens 7 is arranged on the galvanometer 4 to deflect light On the exit path, the light exit of the field lens 7 is provided with a printing platform 9, and the distance between the printing platform 9 and the field lens 7 remains constant; the printing platform 9 is used to place molding materials; the thickness of the molding material of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com