Interlayer reinforcement technology for 3D printing of fiber reinforced composite

A technology of interlayer enhancement and 3D printing, applied in the direction of additive processing, 3D object support structure, additive manufacturing, etc., can solve the problems of poor interlayer bonding force, no improvement, and limited development, etc., to achieve good intralayer performance, Improve the effect of weak inter-layer performance and expand the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

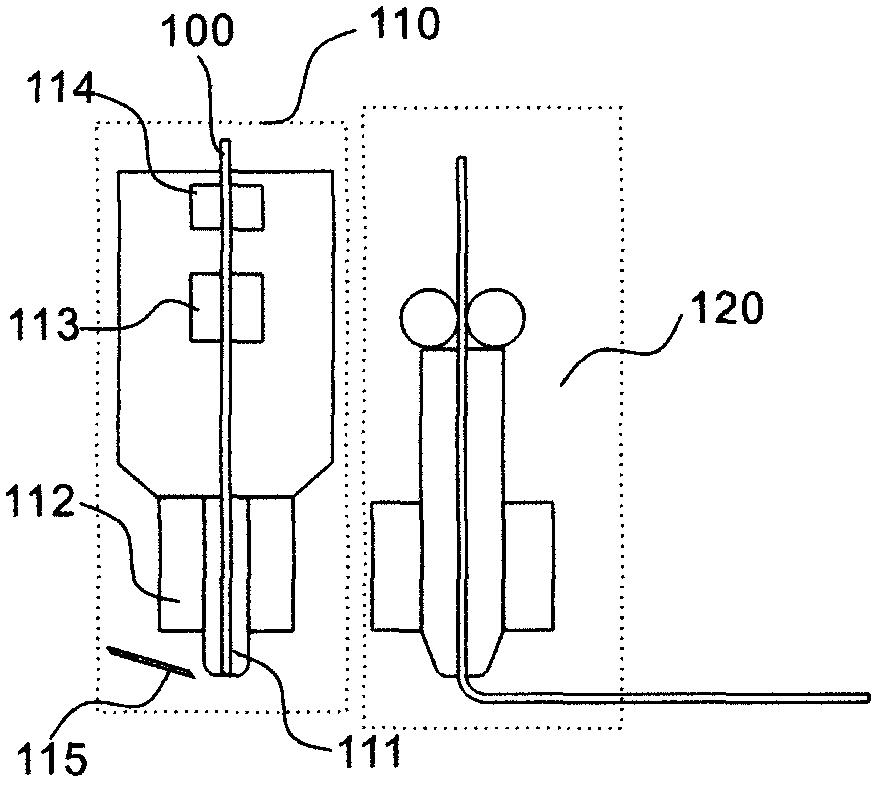

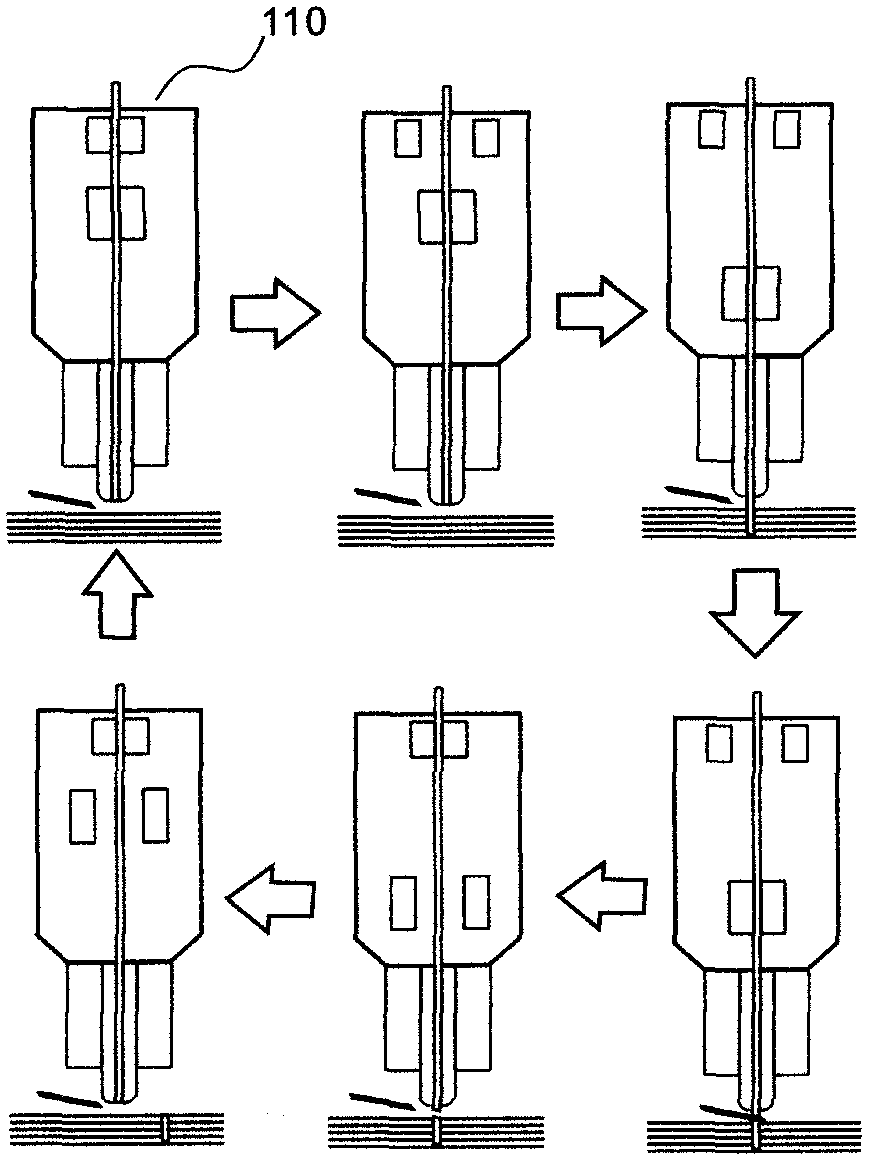

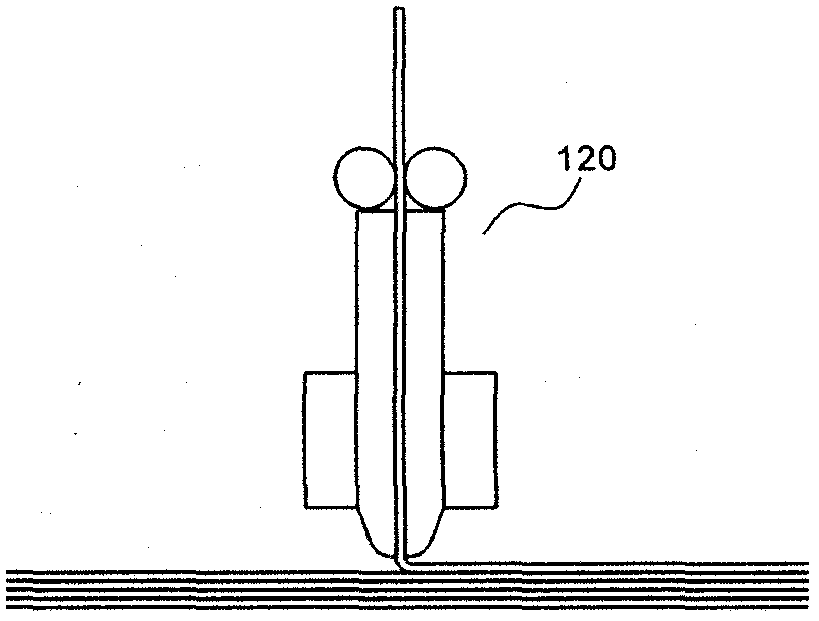

[0021] The fiber-reinforced thermoplastic 3D printer in this embodiment has two nozzles, one nozzle is used to print continuous fiber-reinforced thermoplastic materials in the plane of the product (referred to as in-plane nozzle 120), and the other nozzle is a special nozzle for interlayer reinforcement (referred to as reinforcement nozzle 110). The interlayer reinforcement of 3D printed products is realized in the process of printing multiple layers of two-dimensional laminated intralayer materials by the 3D printer. The reinforcement nozzle 110 includes a heating device (guiding tube 111 and heating tube 112), a pushing mechanism (pushing block 113 and clamping block 114) and cutting mechanism (cutting knife 115), such as figure 1 As shown, wherein, the heating tube 112 heats the guide tube 111, and the guide tube 111 can transfer heat to the reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com