Plasma processing apparatus

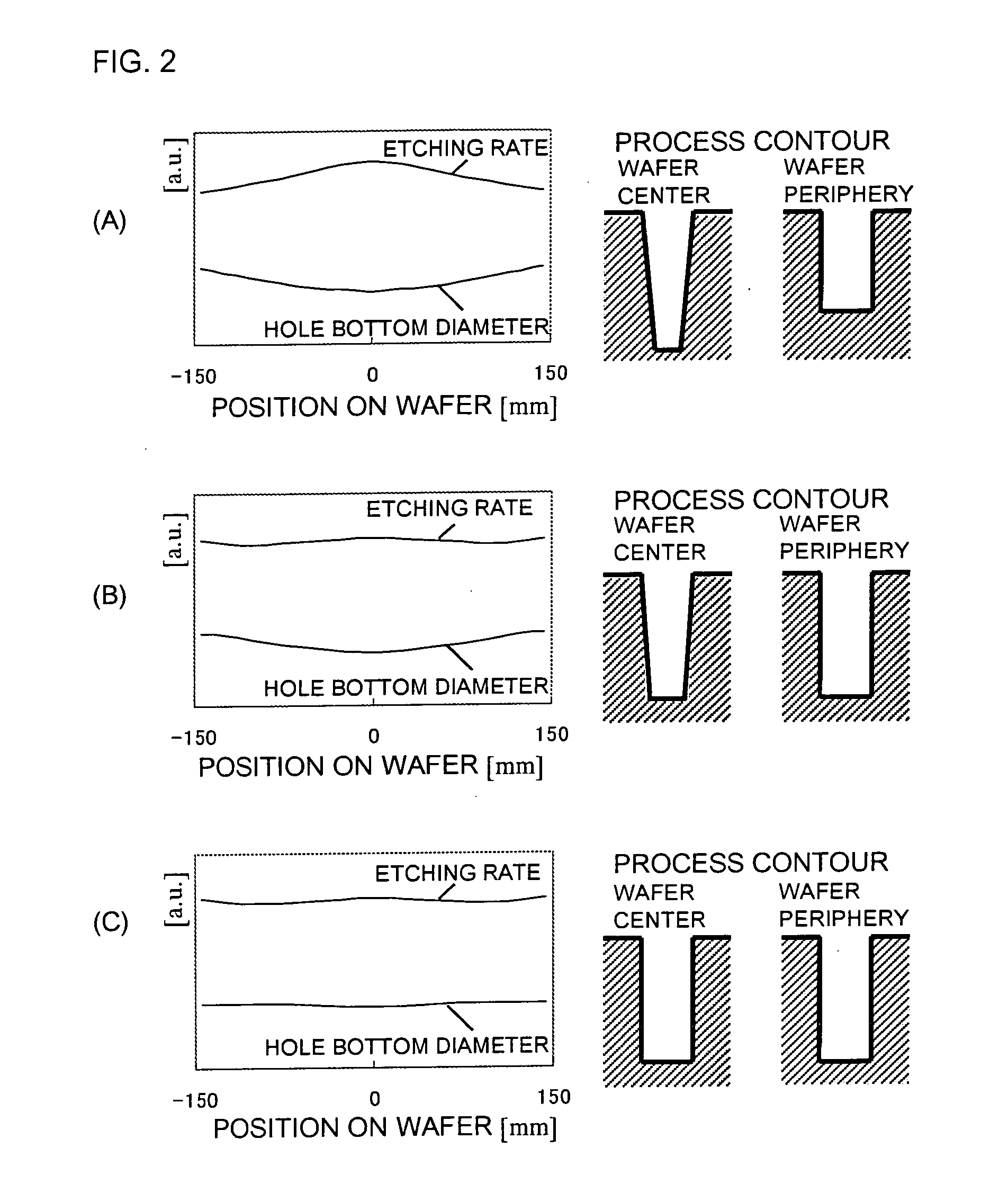

a processing apparatus and plasma technology, applied in the direction of chemical vapor deposition coating, transportation and packaging, coatings, etc., can solve the problem that the critical dimension of the bottom portion of the hole and trenches cannot be easily reached by the interface between the deposition film and the object to be processed, and the etching rate is deteriorated or the etching is stopped before it is completed, so as to improve the uniformity of both the process depth and the critical dimension across the plane of the obj

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

third embodiment

[0060]FIG. 7 is an enlarged view showing the portion where the gas dispersion plate 10 is divided into two areas, one area for dispersing the processing gas introduced through the inner gas holes into the processing chamber, and the other area for dispersing the processing gas introduced through the outer gas holes into the processing chamber. two gas dispersion plates 10-1 and 10-2; one superposed on the other, are used to disperse the processing gas. The gas dispersion plates 10-1 and 10-2 are divided into two areas, respectively, with ring-shaped partitions (for example, O-rings) 12-1 and 12-2. Moreover, the gas dispersion plates 10-1 and 10-2 are screwed using as crew 32 onto the antenna 3 via an aluminum spacer 33, for example, in order to prevent the gas dispersion plates 10-1 and 10-2 from being bent by the thickness of the O-rings. Furthermore, the gas dispersion plates 10-1 and 10-2 and the antenna 3 are separated via an insulator 31 so as to enable different RF power to b...

fourth embodiment

[0064] Next, the present invention will be described with reference to FIG. 9. According to the apparatus of the present embodiment, two RF power supplies 5A and 5C with different frequencies are connected to the electrode 4 via matching networks 6A and 6C, respectively. The present apparatus generates plasma through the RF power supplies from the RF power supplies 5A and 5C and controls the distribution of plasma by the balance of power output from the RF power supplies 5A and 5C.

[0065] In order to perform uniform etching across the plane of the object according to the present apparatus, for example, the balance between the output power of RF power supply 5A and the output power of RF power supply 5C is adjusted to control the plasma distribution and to uniformize the process depth across the plane of the object. Thereafter, by controlling the flow ratio of O2 or N2 supplied via gas outlets 36-1 and 36-2 of the top plate and through the inner gas holes and the outer gas holes of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com