Nano-scale high-precision additive manufacturing equipment

An additive manufacturing and high-precision technology, applied in the field of additive manufacturing, can solve the problems of difficulty in pulling ultra-fine droplets, inaccurate deposition of droplets, and limited printing accuracy, avoiding complex secondary weaving and small gaps. , Improve the effect of printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

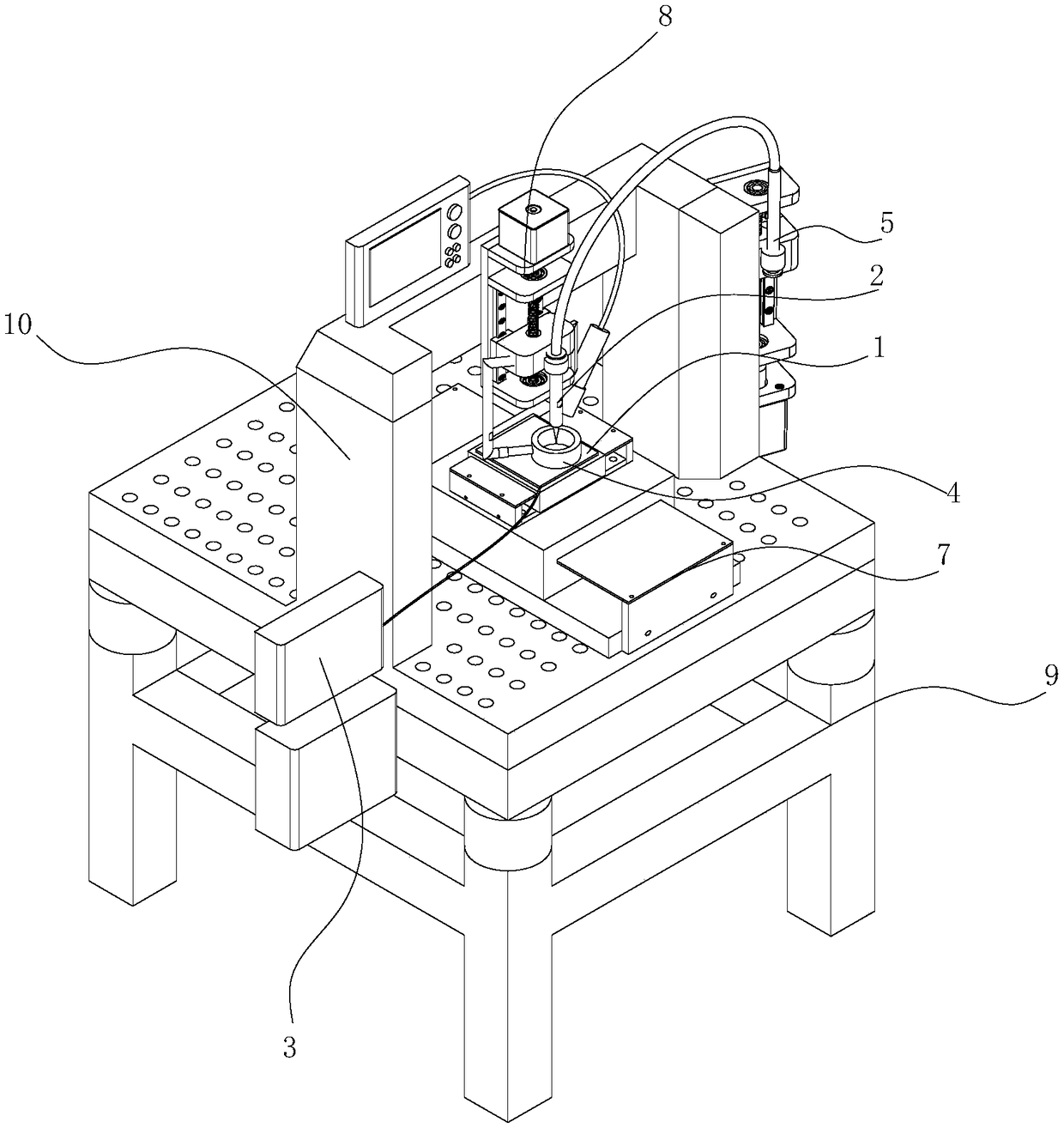

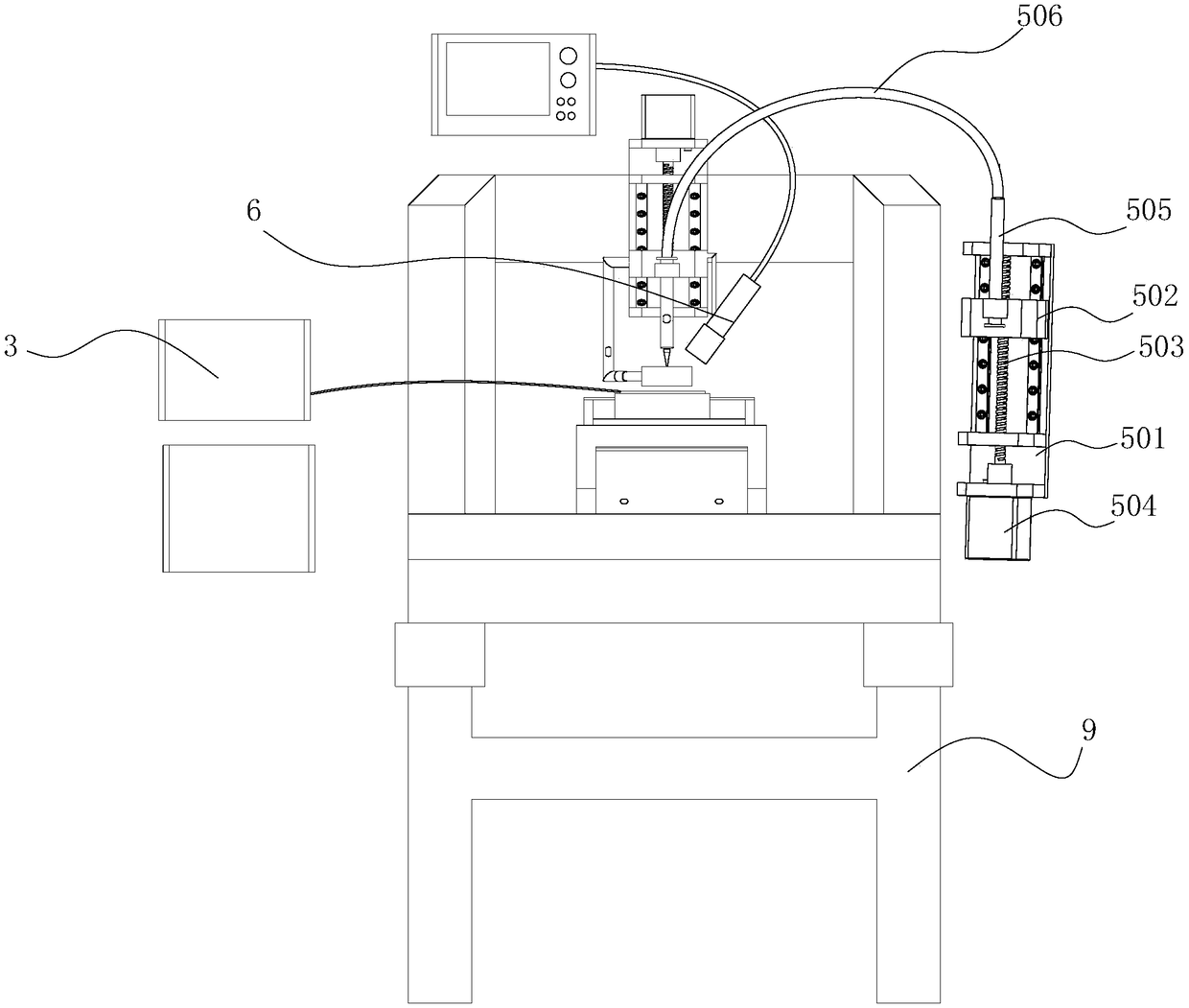

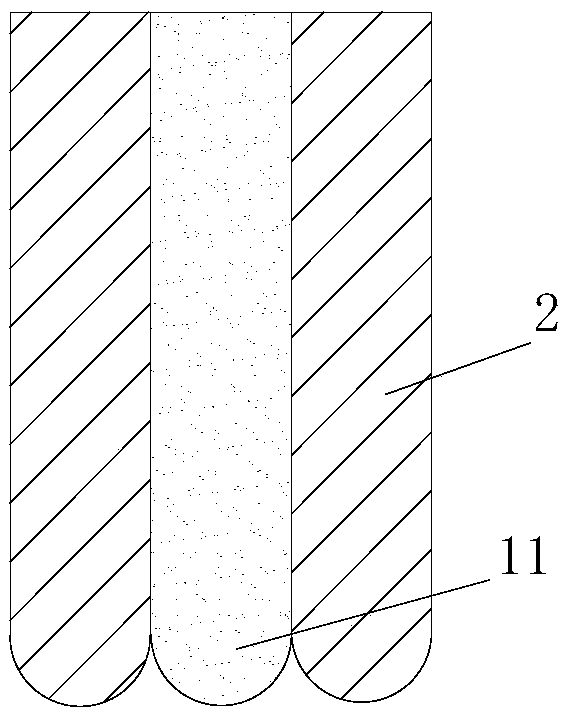

[0047] see figure 1 and figure 2 , in one embodiment, the nanoscale high-precision additive manufacturing equipment includes a printing platform 1 and a printing nozzle 2, the printing nozzle 2 is arranged above the printing platform 1 and the nozzle is facing the printing platform 1, and the conductive nozzle of the printing nozzle 2 A high-voltage pulse power supply is applied between the printing platform 1. There is also a uniform magnetic field (not shown in the figure) perpendicular to the printing platform between the printing platform 1 and the printing nozzle 2, the direction of the magnetic field line is facing the printing platform 1, and the distance D between the printing platform 1 and the printing nozzle 2 satisfies the following relationship Mode:

[0048] D=N×T×V 平

[0049] in,

[0050] m is the mass of each drop of pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com