Multi-material digital light processing (DLP) three-dimensional printing method and printing equipment thereof

A technology of 3D printing and 3D printer, which is applied in metal processing equipment, additive processing, 3D object support structure, etc. It can solve the problems that restrict the popularization and application of technology, and cannot use multiple photosensitive resin materials to print at the same time, so as to broaden the application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The core of the present invention is a multi-material DLP three-dimensional printing method and its printing equipment. In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

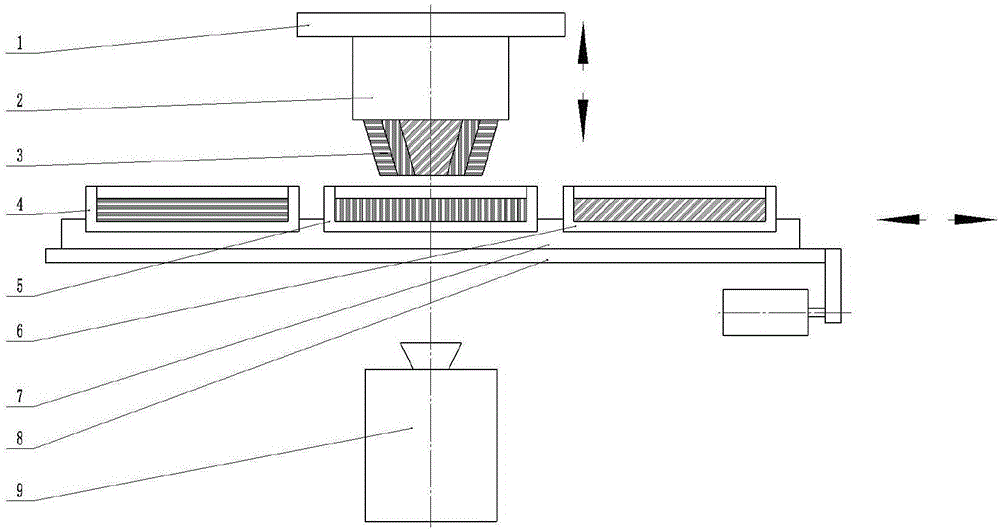

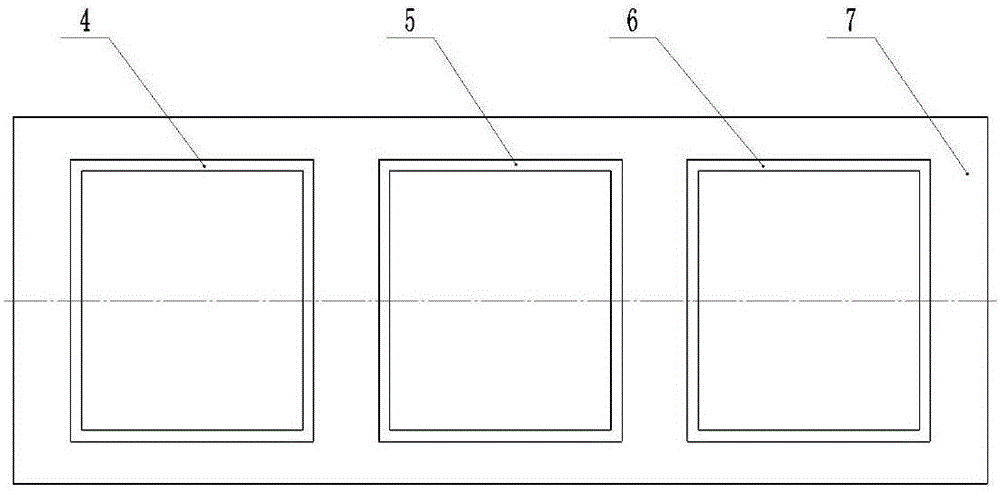

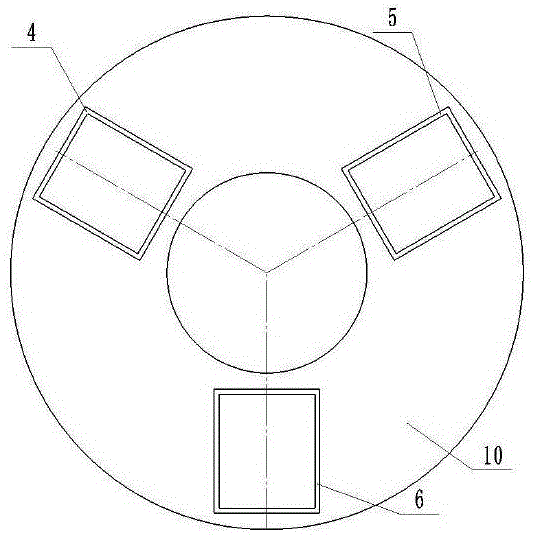

[0019] refer to figure 1 , figure 1 It is a front structural view of a preferred embodiment of a multi-material DLP three-dimensional printer. Since the multi-material DLP three-dimensional printer proposed by the present invention can print two or more photosensitive resin materials, the number of specific resin tanks installed can be adjusted according to the needs of actual model printing. In this embodiment, three resin tanks are taken as an example for illustration.

[0020] A multi-material DLP three-dimensional printer, the printer includes a vertical motion platform 1, a model building table 2, a first resin tank 4, a second re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com