Connector for laundry rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As a preliminary matter, references to upper, lower, right, left, forward and rear are for convenience and are not meant to limit the scope of the aspects of the laundry rack.

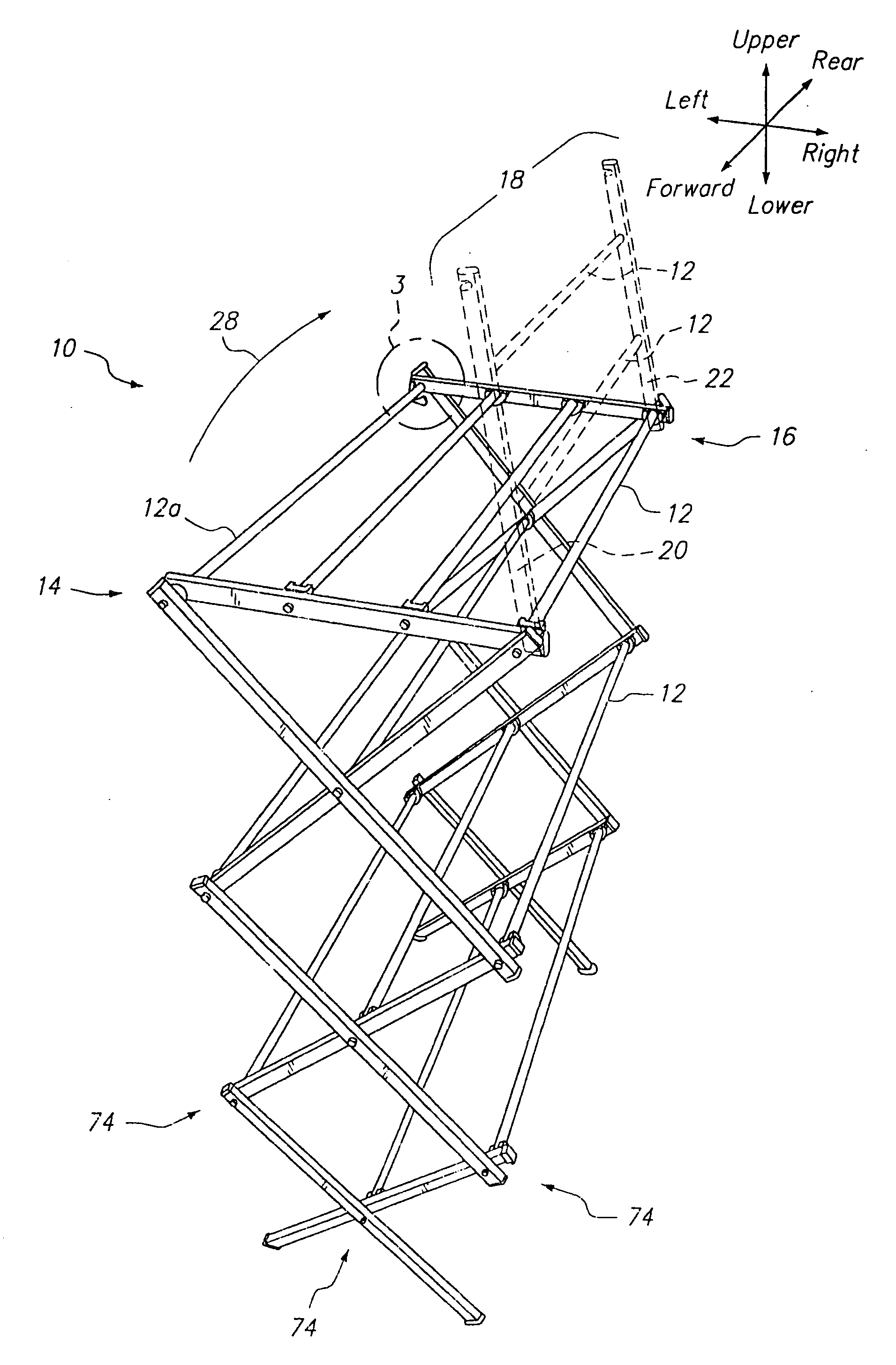

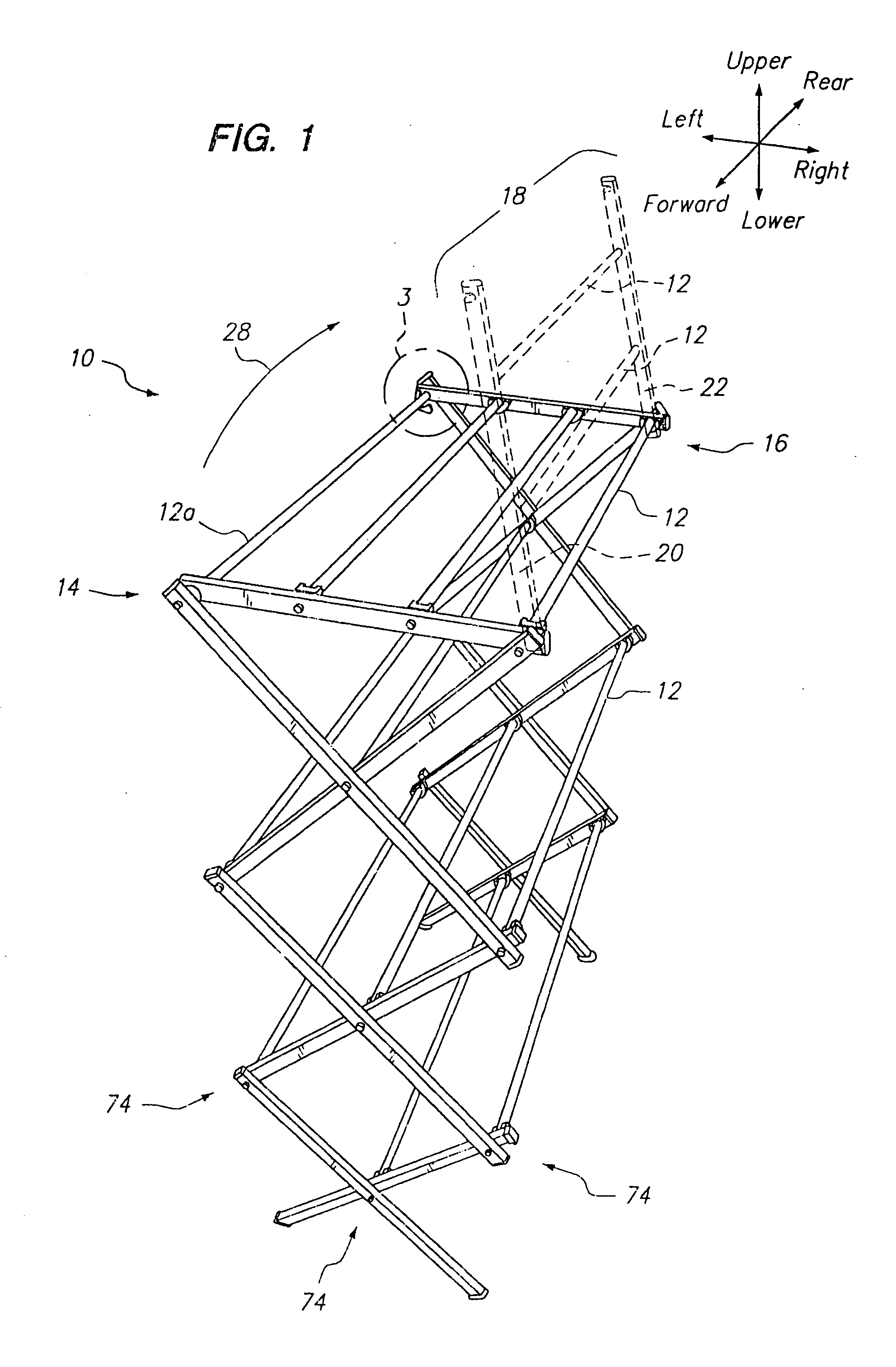

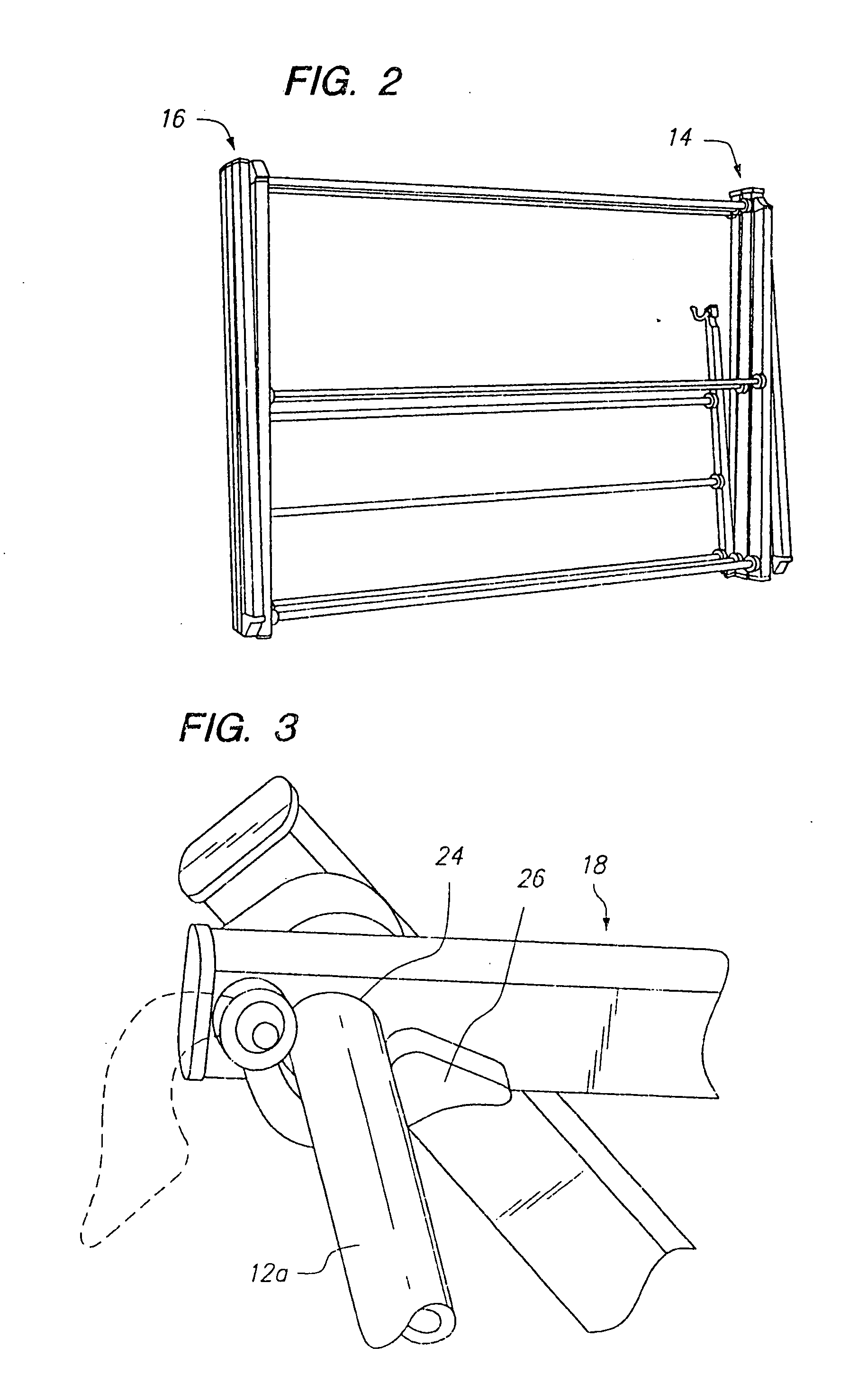

[0030] Referring now to the drawings which are for the purposes of illustration and not for the purposes of limiting the laundry rack 10 which will be described herein, FIG. 1 shows a perspective view of a laundry rack 10 which is collapsible into a folded position (See FIG. 2) and expandable to an upright position (See FIG. 1). Cross members 12 are disposed apart from each other such that laundry (e.g., shirts, pants, etc.) may be hung over the cross members 12 for air drying. After the clothes are air-dried, the user may remove the clothes and traverse the laundry rack 10 to the folded position (See FIG. 2) for compact storage. The laundry rack 10 provides a convenient mode of storage by being collapsible to the folded position so as to occupy a minimal amount of space. The folded laundry rack may the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com