Method for achieving mutual conduction of inner and outer surfaces of plastic component

A technology of inner surface and outer surface, applied in the direction of radiating element structure, chassis/cabinet/drawer parts, antenna grounding switch structure connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

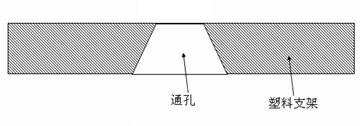

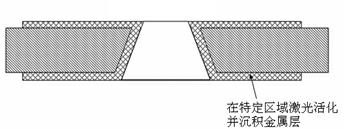

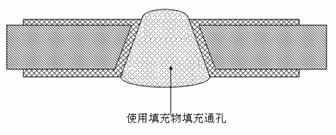

[0039] see Figure 2A - Figure 2C A method for realizing mutual conduction between the inner surface and the outer surface of a plastic part, comprising the following steps:

[0040] Drill through holes at predetermined positions of the plastic parts, the diameter of which is about 0.02-0.5MM, preferably, the diameter of the holes is about 0.05-0.3; The method of forming via holes includes at least one of laser drilling, ultrasonic drilling and mechanical drilling.

[0041] Activate and deposit the metal layer 12 in a specific area, realize the electrical conduction between the inner surface and the outer surface of the plastic part through the metal layer 12 and do not use fillers to block the hole, the specific area includes at least the inner wall of the hole and the inner surface of the plastic part connected to the inner wall of the hole and the inner surface of the plastic part. outer surface area.

[0042] The holes are generally conical, smaller at one end and larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com