Preparation method of 1,2-propane diamine

A technology of propylene diamine and isopropanolamine, applied in 1 field, can solve the problems of high cost of raw materials, backward technology and high pressure, and achieve the effects of reducing investment and production efficiency, simplifying process steps, and no pollution discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

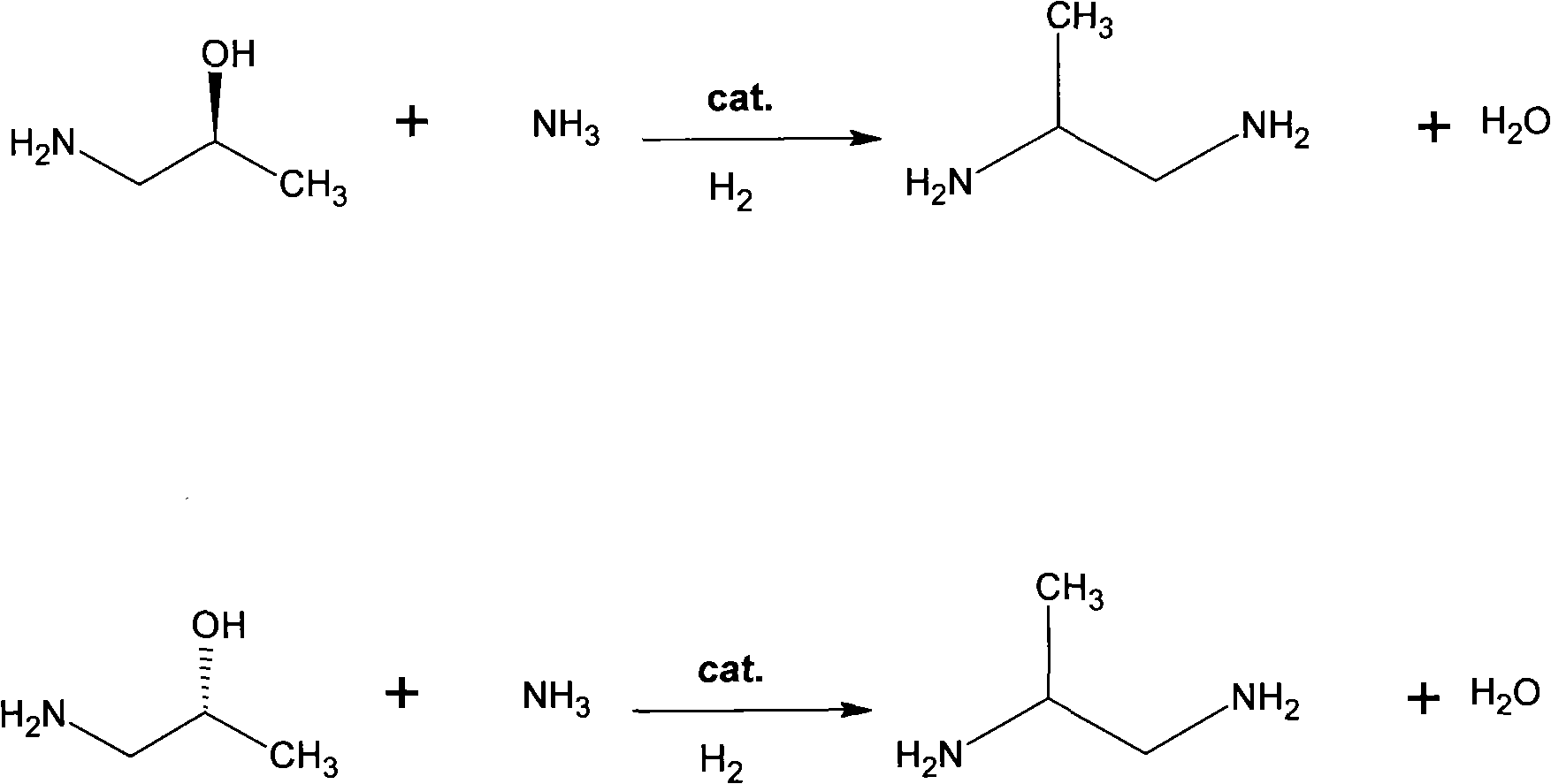

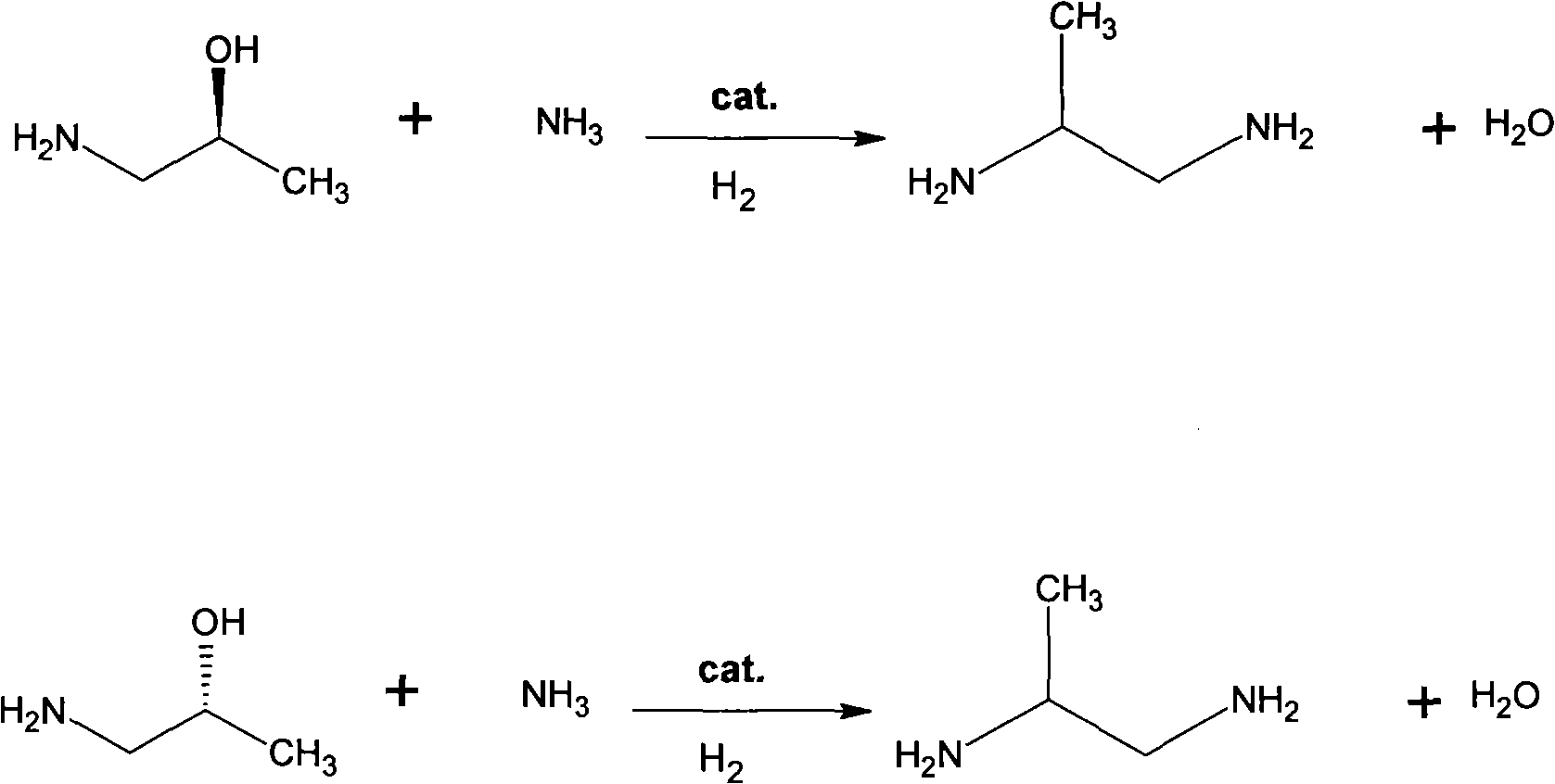

Image

Examples

Embodiment 1

[0027] Weigh 150g of one isopropanolamine, 150g of deionized water, Cu-Co / Al 2 o 3 Add 1.5 g of the catalyst into a 1L autoclave, replace with nitrogen and hydrogen respectively, then feed 150 g of anhydrous liquid ammonia, then feed 0.5 Mpa hydrogen, start stirring, raise the temperature to 180°C and keep it for 8 hours. Cool down and vent to normal pressure, discharge the material, filter the catalyst, and rectify the clear liquid to obtain 119g of the product.

Embodiment 2

[0029] Weigh 150g of isopropanolamine, 150g of deionized water, 1.5g of Cu-Co / diatomaceous earth catalyst into a 1L autoclave, replace with nitrogen and hydrogen respectively, and then introduce 170g of anhydrous liquid ammonia, and then introduce 1.0 Mpa hydrogen, start stirring, raise the temperature to 150°C and keep it for 6 hours. Cool down and vent to normal pressure, discharge the material, filter the catalyst, and rectify the clear liquid to obtain 114g of the product.

Embodiment 3

[0031] Weigh 150g of one isopropanolamine, 150g of deionized water, Cu-Co / Al 2 o 3 - Add 1.5 g of diatomite catalyst into a 1L autoclave, replace with nitrogen and hydrogen respectively, then feed 160 g of anhydrous liquid ammonia, then feed 0.5Mpa hydrogen, start stirring, raise the temperature to 170°C and keep it for 6 hours. Cool down and vent to normal pressure, discharge the material, filter the catalyst, and rectify the clear liquid to obtain 121g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com