Industrialization reutilization device of environment protection type organic refuse and manufacturing technique thereof

A technology of organic waste and production process, which is applied in the field of industrial recycling equipment and production process of environment-friendly organic waste, which can solve the problems of secondary environmental pollution, difficult decomposition of landfill parts, secondary pollution, etc. The effect of advanced technology, remarkable social and ecological benefits, and stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

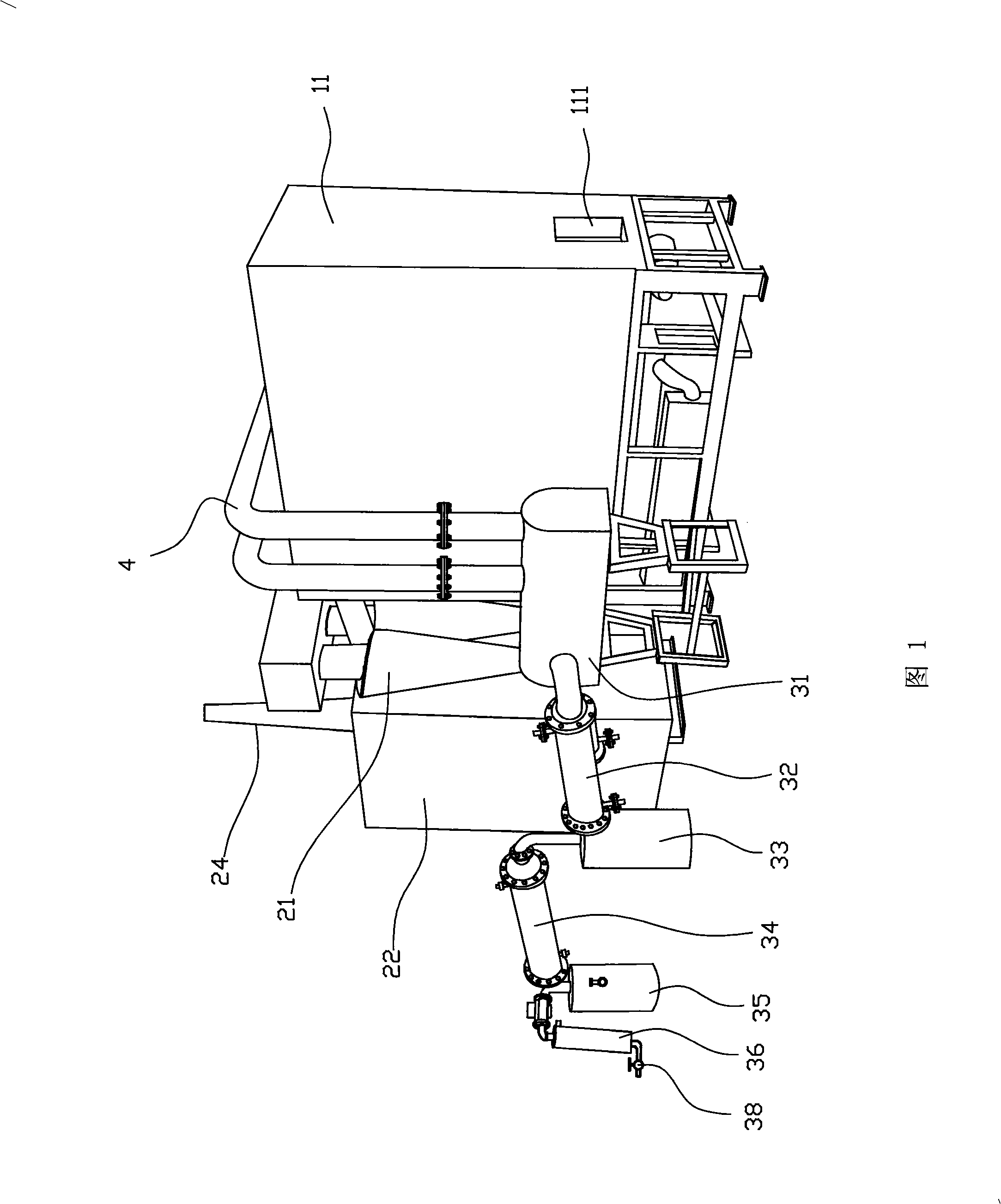

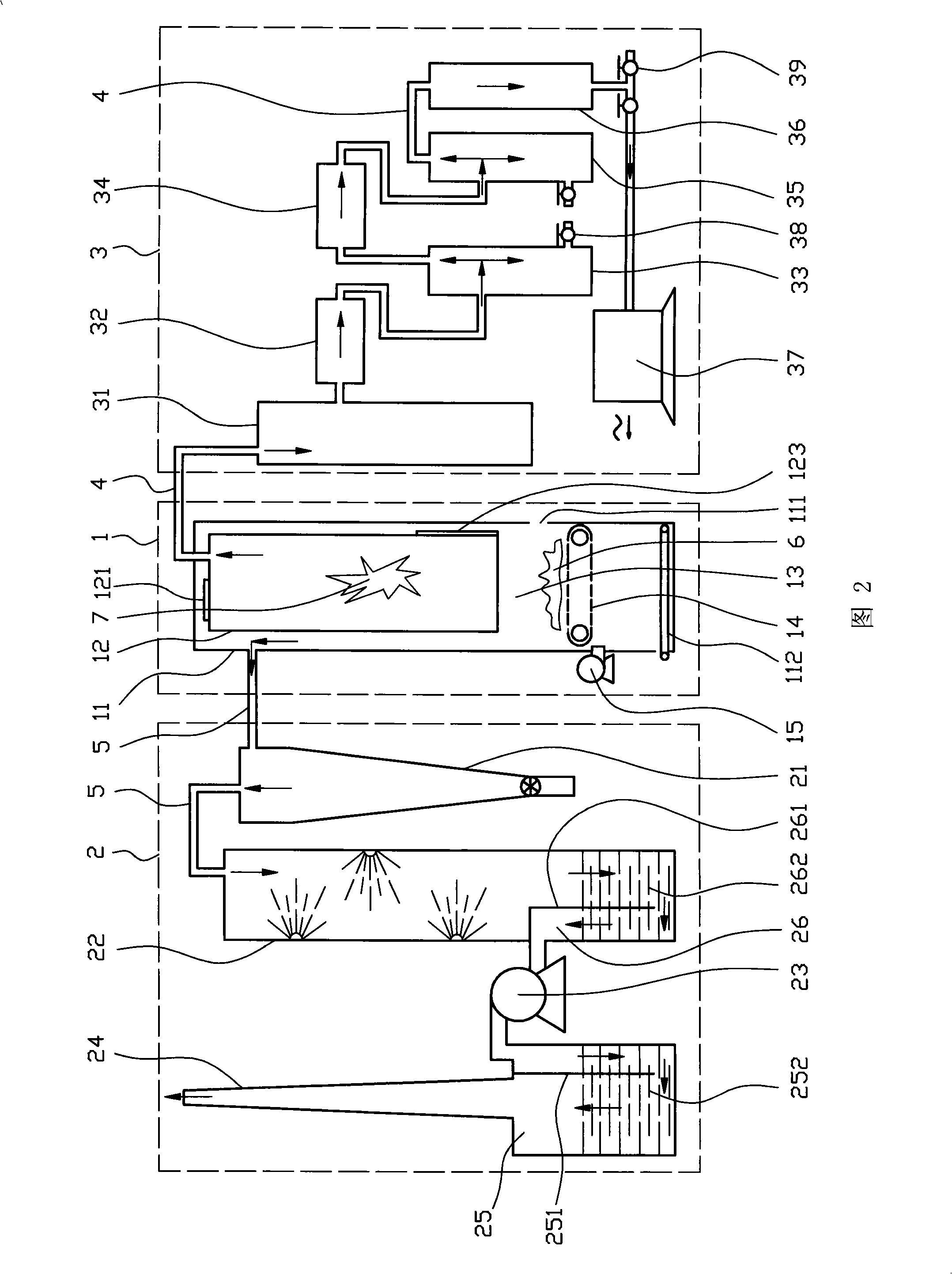

[0027] The present invention will be further described below with specific embodiments in conjunction with the accompanying drawings, see Fig. 1-2;

[0028] The industrial recovery and utilization equipment of environment-friendly organic waste includes: an atmospheric pressure heating reaction device 1, a flue gas purification device 2 and a gas recovery device 3, the flue gas purification device 2 communicates with the furnace 13 at the upper part of the inner cavity of the furnace body 11, The gas recovery device 3 communicates with the inner cavity of the reaction kettle 12 at the upper part of the inner cavity of the furnace body 11, wherein:

[0029] Atmospheric pressure heating reaction device 1: including a furnace body 11 made of heat-insulating material, a reactor 12 is arranged on the upper part of the inner cavity of the furnace body 11, a furnace 13 for heating the reactor is arranged in the middle, and a fuel delivery device is arranged on the lower part of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com