Waste paper regeneration environmental protection device and method

An environmental protection equipment and technology for waste paper, applied in the field of papermaking methods and equipment, can solve the problems of low quality of recycled paper, low fiber utilization, difficulty in automatic control, etc. The effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

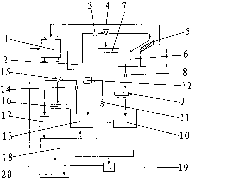

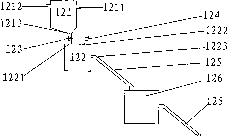

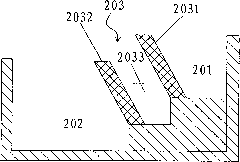

[0026] Such as figure 1 , figure 2 , image 3 As shown, the recycling process: after the recovered waste paper is cleaned, it is sent to the hydropulper 1 with water in a ratio of 1:1 to 2.0 to decompose into pulp. Then the pulp is pumped into the first desander 4 through the pump 3 for desanding. The pulp after desanding is divided into 5 parts by inclined sieving, and its water is returned to the hydraulic pulper 1, and its pulp is introduced into the second pulp pool 6. A sand sinking ditch 7 is arranged below the first desander 4 and is connected with the second slurry tank 6 . In the sand sinking ditch 7, the heavier sand will sink to the bottom, and the lighter pulp will float up and flow into the second slurry tank 6 together with the water. The pulp in the second pulp tank 6 is pumped into the refiner 9 through the water pump 8 for refining. The pulp after refining is introduced into the third stock chest 10 . The paper pulp in the 3rd stock pool 10 enters head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com