Treatment technology of automobile wheel assembly before painting primer

A treatment process and wheel technology, which can be used in surface pretreatment, devices for applying liquid to surfaces, coatings, etc., which can solve the problems of difficult wastewater treatment, large footprint, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

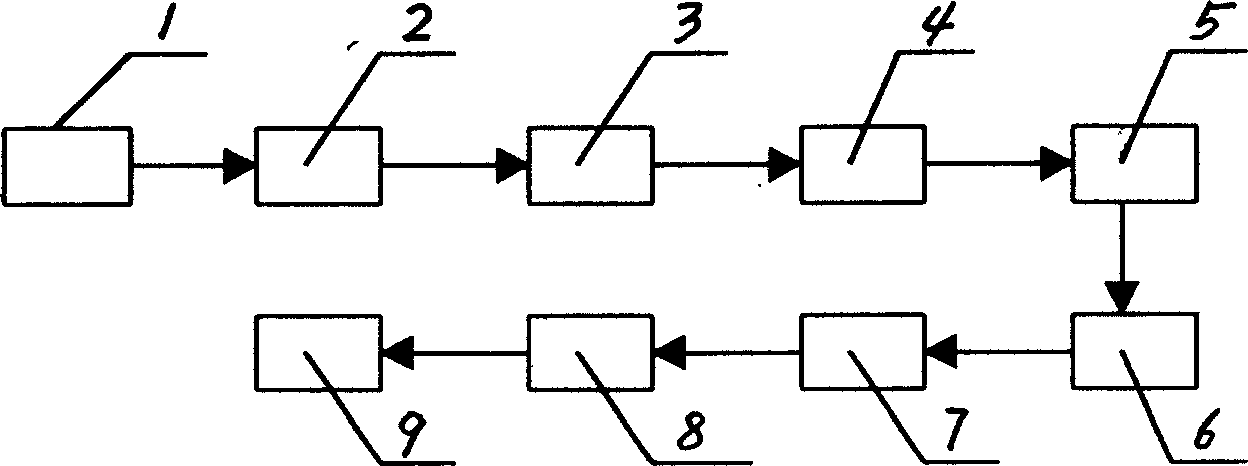

[0017] Example: As shown in the accompanying drawings, the treatment process before the primer coating of the automobile wheel assembly is: shot blasting 1, pre-cleaning 2, on-line 3, degreasing 4, primary washing 5, secondary washing 6, phosphating 7 , three washings 8 and clean deionized water washing 9.

[0018] Include the following nine steps:

[0019] a. Hang the wheel assembly with the corresponding shot blasting hanger into the shot blasting machine for shot blasting;

[0020] b. Use compressed air to clean the floating ash and steel shots on the surface of the workpiece;

[0021] c. Hang the workpiece with a swimming paint hanger;

[0022] d. Enter the alkali washing tank for degreasing treatment;

[0023] e. Perform a water wash;

[0024] f. Carry out secondary washing;

[0025] g. Phosphating the workpiece;

[0026] h, wash three times;

[0027] i. Wash with clean deionized water.

[0028] The present invention no longer adopts the general strong acid pickli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com